What WPC Flooring Is

WPC flooring stands for Wood Plastic Composite flooring. It’s a modern type of engineered floor for homes and businesses. The core blends recycled wood fibers or wood flour with thermoplastic resins like PVC, PE, or PP. Wood makes up 30%–70% of the plank’s mass. The result? A dense, waterproof core. It has the warmth and strength of wood plus the flex and toughness of plastic.

Key Components and Structure of WPC Foloring

Understanding how WPC planks are built: A typical plank has several layers stacked together:

Backing Layer: This is the foundation. It’s often made of foam or cork. It gives stability, dampens sound, and blocks moisture. This layer helps the plank lay flat. It also creates a softer, quieter feel under your feet.

Core Layer (WPC Core): This is the heart of the plank. It mixes wood fibers, plastics, and additives. These additives include foaming agents, binders, UV stabilizers, and colorants. The core is waterproof and strong. It resists swelling, shrinking, and warping.

Printed Vinyl Layer: This layer uses high-quality prints. It mimics wood, stone, or tile looks. You get a wide range of design choices.

Wear Layer: This is a tough, clear top coat. It’s made of urethane or ceramic beads. It protects against scratches, stains, and fading. Wear layers range from 6 mil to 20 mil. Thicker layers last longer and come with better warranties.

Properties and Performance

Here’s what WPC flooring delivers:

Water Resistance: WPC planks don’t swell or warp when exposed to moisture. I suggest them for kitchens, bathrooms, basements, and other damp spaces.

Durability: The rigid core and strong wear layer work together. They resist wear, scratches, and dents. This makes them great for busy commercial areas.

Comfort & Insulation: WPC feels softer and warmer underfoot than tile or stone. It also blocks sound better and keeps heat in.

Installation Ease: Most WPC products have a simple click-lock system. You can install them as a floating floor over most subfloors. No glue or nails needed.

Low Maintenance: You don’t need to sand, polish, or refinish. Just sweep and mop when needed.

Sustainable Choices: Many WPC floors use recycled materials. This reduces environmental impact. But sustainability depends on how each brand sources and makes its products.

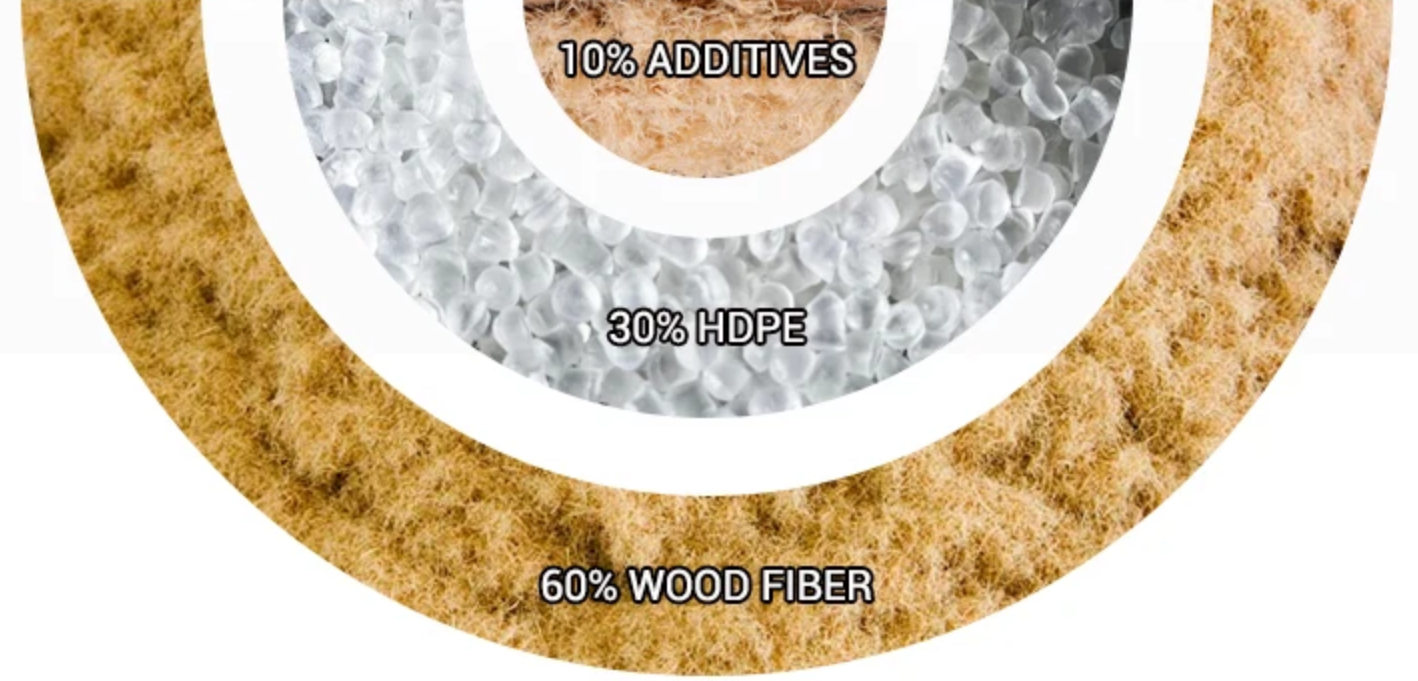

Typical Composition Example

A standard WPC plank might include:

– 50% wood fiber

– 40% PVC

– 10% additives (foaming agents, stabilizers, colorants, and sometimes antimicrobial agents)

Design Versatility

Advanced printing technology makes WPC flooring look like natural materials. It can mimic oak, maple, walnut, stone, and even tile. You get varied looks without the upkeep or limits of real wood or stone.

For specific technical specs or formulas, check with the manufacturer. Compositions and performance levels vary by brand and model.

Material Composition of WPC Flooring

WPC (Wood Plastic Composite) flooring is made from natural wood fibers and thermoplastic polymers. The main plastic used is PVC (polyvinyl chloride). Some manufacturers also use PE (polyethylene) or PP (polypropylene).

The wood content in a WPC plank ranges between 30% and 70% by mass. Many brands use recycled wood flour, sawdust, or bamboo fiber. This makes the product more sustainable. The plastic acts as a binder. It gives the floor water resistance, flexibility, and structural strength.

Key Ingredients and Additives

Wood fibers (30%–70%): Core reinforcement, providing a natural feel and texture.

Thermoplastic resin (PVC most common, also PE or PP): Delivers waterproofing, durability, and flexibility.

Calcium carbonate: A stabilizing filler that improves structural stability and reduces material cost.

Plasticizers: Enhance flexibility and resilience.

Foaming agents: Lighten the core and boost underfoot comfort.

UV stabilizers: Crucial for color retention and resistance to sunlight, particularly outdoors.

Colorants & antimicrobial agents: Add color variation and extra defenses against mold and bacteria.

Core Layer Breakdown

The WPC core is the heart of the composite. It combines these materials in layers. This design maximizes water resistance and durability. It also minimizes expansion, contraction, and warping. Real wood often suffers from these problems.

Typical composition ratios (by weight) for a high-quality WPC plank:

– 50% wood fiber (or bamboo)

– 40% PVC plastic

– 10% stabilizers, foaming agents, colorants, and other additives

Lower-quality versions use extra calcium carbonate as filler. This may lower cost. But it also reduces durability and performance. I recommend avoiding these cheaper options.

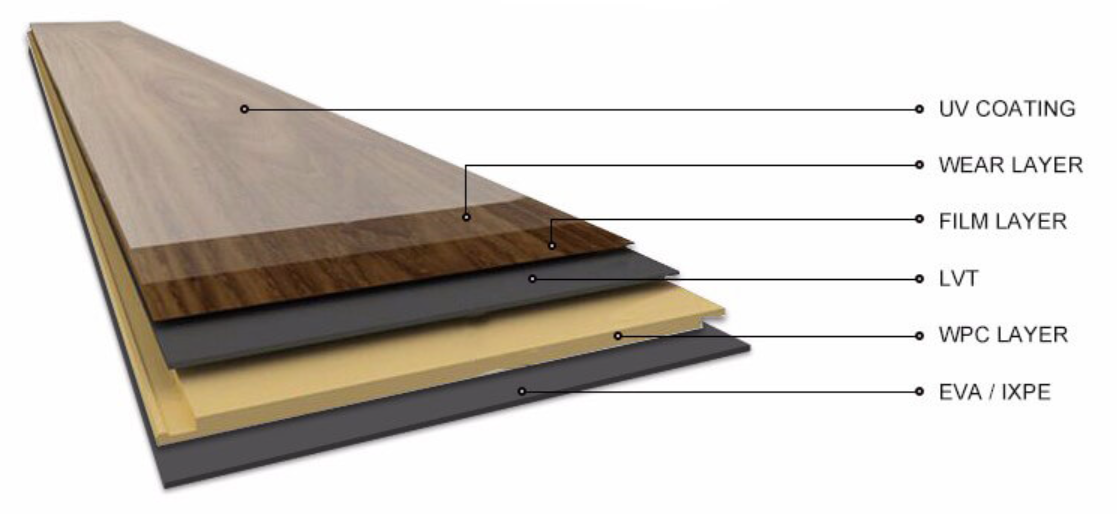

Layered Construction

A WPC flooring plank consists of four main layers:

Backing (underlayment) layer: Made from cork or foam. This layer handles sound dampening and minor moisture protection.

WPC core layer: Wood fibers and plastics (plus additives) are fused together. This creates superior strength. It also resists water and dents.

Printed vinyl décor layer: A high-resolution photographic film. It simulates the texture and patterns of real wood, stone, or tile.

Wear layer: A transparent, tough topcoat (often urethane or ceramic bead-reinforced). It protects against scratches, scuffs, stains, and UV fading. Wear layer thickness ranges from 6 mil up to 20 mil. This thickness affects lifetime and warranty coverage.

Layer Structure and Function of WPC Flooring

Why WPC (Wood Plastic Composite) flooring works so well. Understanding each layer helps you see what makes it perform, feel comfortable, and last long. Here’s what each layer does, what it’s made from, and how it helps you in real life. I’ve broken this down for both homeowners and business users.

WPC Flooring Layers: Construction and Key Roles

Wear Layer:

Material: Urethane, aluminum oxide

Thickness: 0.3mm–0.5mm (higher grades can reach up to 0.7mm for commercial use)

Function: This tough, clear layer protects against scratches, stains, and everyday wear. Advanced versions also have UV coatings to fight fading. A thicker wear layer resists dents better. It stands up to pet claws and high heels. This makes your floor last longer. I recommend it for busy areas.

Design (Decorative) Layer:

Material: High-resolution printed films

Function: This layer creates realistic visuals that look like hardwood, stone, or tile. Some use embossed textures and 3D printing for more authenticity. This gives WPC its visual flexibility. You can choose from classic oak to modern marble styles. Based on my experience, this variety meets most design needs.

LVT Core Layer (Optional):

Material: 100% PVC or a mix of PVC and plasticizers

Thickness: 2mm–5mm (varies by product)

Function: LVT provides a flexible, waterproof base. Its fully synthetic core allows for thinner construction while maintaining durability. It ensures dimensional stability, moisture resistance, and easy maintenance. LVT works well in high-traffic commercial and residential spaces and supports advanced locking systems. This layer is optional depending on product design or customer preference.

WPC Core Layer:

Material: Extruded composite of wood fibers (up to 60% cellulosic) and plastic polymers (PVC or PE, sometimes with recycled plastics)

Thickness: 4mm–8mm

Function: The core provides the waterproof foundation. It’s built for stability, shock absorption, and warmth underfoot. Some new versions use stone powder and virgin plastics instead of wood. This boosts moisture defense even more. WPC works great in kitchens, bathrooms, basements, or any humid place. I like this feature because it prevents water damage.

Backing Layer:

Material: IXPE/EVA foam or natural cork

Thickness: 1mm–2mm

Function: This layer insulates sound and adds comfort. It absorbs footsteps. It reduces impact noise by up to 19dB compared to harder surfaces. It also covers up subfloor imperfections. The result? You get quieter floors. They feel softer than regular options.

Detailed Layer Functions and Benefits

| Layer | Material / Design | Thickness | Key Function & Benefit |

|---|---|---|---|

| Wear | Urethane, aluminum oxide | 0.3–0.5mm | Shields from wear, stains, UV; provides durable, low-maintenance floor |

| Design | Printed decor film | Thin film | Provides realistic wood/stone looks; aesthetic flexibility |

| Core (WPC) | Wood fiber + plastic (PVC/PE) | 4–8mm | Delivers stability, waterproofing, warm/soft feel; prevents swelling |

| Backing | IXPE/EVA foam or cork | 1–2mm | Sound insulation, shock absorption, smooths subfloor |

| Core (LVT) (Optional) | 100% PVC or PVC + plasticizers | 2–5mm | Flexible, waterproof synthetic base; stable, easy to maintain; suitable for high-traffic areas |

Technical Highlights

Waterproof Performance: The extruded WPC core means zero wood swelling or warping. There’s no risk of mold. This makes WPC safer and longer-lasting in wet areas. I suggest this for anyone with moisture concerns.

Acoustic Comfort: Foamed backing materials cut noise transmission. This matters in apartments or offices. People value the quiet.

Durability and Maintenance: A strong wear layer handles commercial use. These floors withstand heavy traffic and stay easy to clean. I’ve seen them hold up well over time.

Fast & Flexible Installation: Click-lock systems let you install it yourself. Planks range from 6–9 inches wide and up to 48 inches long. This saves time and money.

How WPC Flooring Works

WPC stands for Wood Plastic Composite. It’s made from wood fibers mixed with thermoplastic polymers. This creates a strong, water-resistant floor. Here’s how it works and why I think it stands out:

Core Composition and Structure

Wood Fiber & Plastic Blend: The core mixes wood fibers (like sawdust or recycled wood) with polymers. These include PVC, polyethylene, or polypropylene. This blend makes the floor stronger. It also gives it a natural look and feel.

Thermoplastic Polymers: These polymers add water resistance and flexibility. WPC performs better than vinyl or laminate in wet areas. I’ve seen it handle humid conditions much better.

Key Functional Benefits

Strong and Stable: The composite core resists scratches and dents. It handles temperature changes well. It also manages humidity shifts without problems.

Waterproof Design: WPC flooring deals with spills and moisture easily. It won’t swell or warp. I recommend it for kitchens and bathrooms based on my experience.

Realistic Appearance: A printed vinyl layer sits on top. It mimics wood, stone, or tile. You can match it to any space you want.

Installation System

Interlocking Mechanism: Most WPC planks use a click-lock system. Some use tongue-and-groove. DIY installation is fast and simple. You don’t need glue or nails.

Advanced Locking Technologies: Some brands offer 5G locking systems. These lock planks on all four sides. This makes installation faster. It also creates a tight, clean finish.

Maintenance and Practical Advantages

Low Maintenance: WPC flooring needs regular sweeping and occasional mopping. That’s it. No sanding, waxing, or refinishing. I like how easy it is to care for.

Aesthetic Flexibility: Advanced printing gives you many wood and stone designs. You’ll find a wide selection to choose from.

Sound and Comfort: Some WPC planks have cork backing. This adds sound insulation. It also makes floors more comfortable to walk on. But note: cork can be sensitive to excess moisture in some settings.

Where WPC Flooring Excels

Residential Spaces: I suggest WPC for homes. It works well in living areas, kitchens, bathrooms, and basements. Its comfort and water resistance make it perfect.

Commercial Use: It’s also great for retail stores, offices, and high-traffic areas. It holds up to wear. It’s easy to maintain.

Innovative Product Features

Cork Backing for Noise Reduction: Some models use cork backing. This improves sound insulation. It makes rooms quieter. I’ve found this feature makes a real difference.

Variety of Designs: Realistic printing gives you options. You can get rustic oak or modern marble. There’s something for almost any interior style.

WPC flooring has a layered structure. It’s engineered for performance. I recommend it if you want flexibility in design, water resistance, and easy installation. It works for homes and businesses alike.