What Baier Offers Canadian Importers & Distributors

Baier serves as your complete manufacturing partner. We solve the common problems Canadian flooring businesses face when buying from Asia. Four key areas make up our value—each one impacts your profits and daily operations.

1. Compliance-First Manufacturing

We build regulatory readiness into every production run. Your laminate flooring ships with complete documentation. This includes formaldehyde emission certificates (CARB Phase 2/TSCA Title VI), floorscore certifications, and wear-layer performance data. CBSA or provincial regulators ask for verification? You have everything ready. No scrambling for missing papers. This protects you from expensive shipment delays. It also shields you from non-compliance penalties. Those penalties can hit thousands of dollars per container.

2. Duty-Smart Chain Structure

CBSA’s new “last sale” valuation rules will change how Canadian importers calculate Value for Duty. We work with your customs broker to structure deals that stay transparent. At the same time, we optimize your duty position. You get clear, auditable pricing at every step—from manufacturer to importer, then importer to distributor. This clarity saves money. Duty changes can shift your landed costs by 8-15%. That shift affects your competitive pricing in a market already hit by interprovincial trade barriers. Those barriers add similar cost burdens each year.

3. Flexible Order Economics

Our minimum orders start at 1,000 m² for stock collections. Custom designs require 3,000 m². Most laminate flooring manufacturers for Canadian importers and distributors ask for 10,000+ m² minimums. That locks up your capital. Baier’s setup lets you test what different regions want. Coastal markets prefer wide-plank oak visuals. Prairie buyers go for rustic textures. You can test these preferences without filling your warehouse.

4. National Distribution Support

Canada’s interprovincial barriers cost distributors real money. The economic friction adds up to CAD 2,900-5,100 per person each year. Baier reduces this through consolidated shipping documentation. It works across all provinces. We label pallets with bilingual compliance marks. You also get province-specific installation guides. Your trucks cross into Quebec, Alberta, or the Maritimes? The paperwork moves without issues.

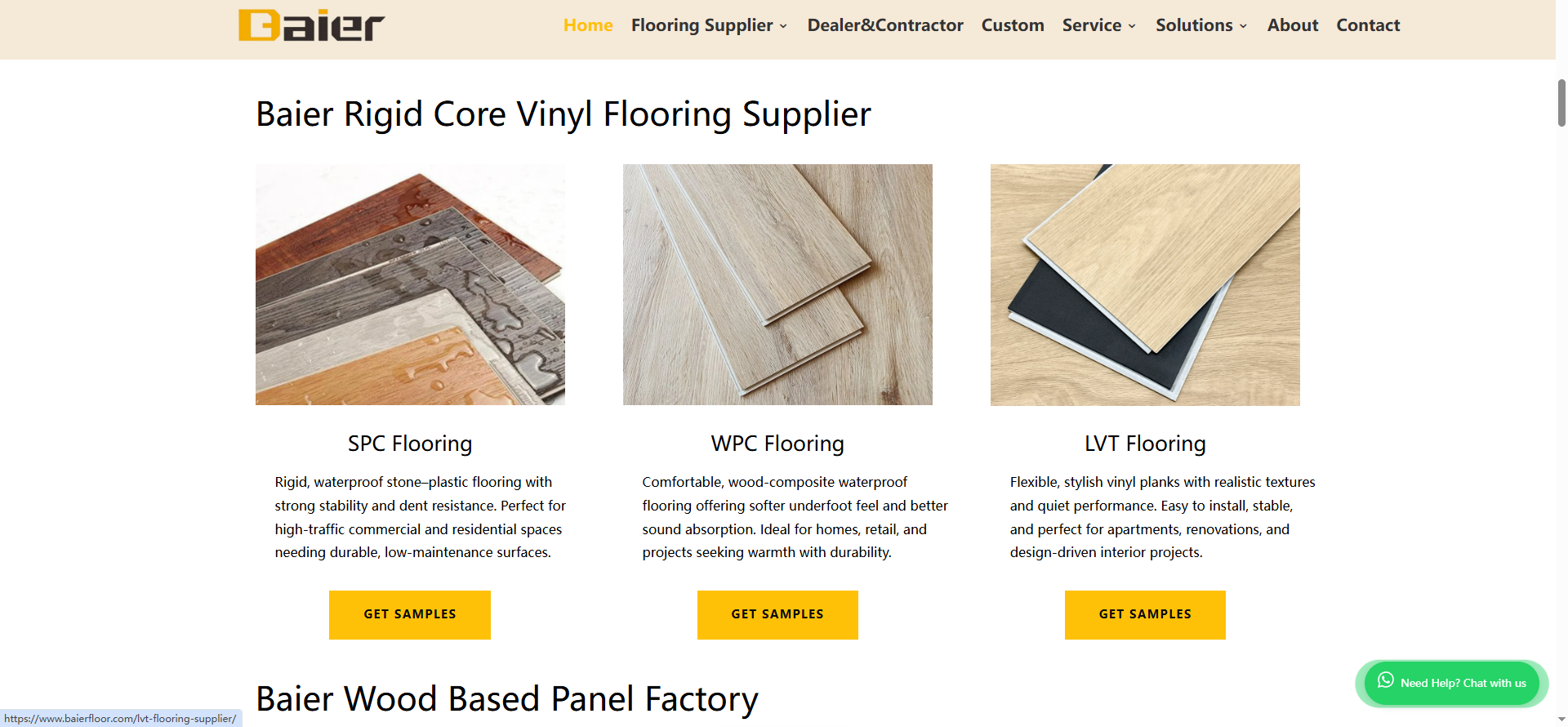

Product Range & Technical Specifications

Baier’s catalog splits into three core lines. Each line focuses on what Canadian buyers install most. Our laminate flooring manufacturer systems follow North American design trends. They meet strict provincial rules across your distribution area.

Residential Collections (AC3-AC4)

Nordic Series gives you wide-plank oak and maple looks in 8mm-12mm thickness. Planks measure 1,220mm × 196mm or 1,380mm × 193mm. These sizes match what Canadian installers prefer for faster coverage. Wear layer rates AC3 work for moderate traffic homes. AC4 handles busy areas like kitchens and family rooms. Each SKU includes:

-

Density : 850-880 kg/m³ HDF Core

-

Embossing : Texture syncs with wood grain visuals (depth variance ±0.2mm)

-

Edge profile : Double-click locking system; tensile strength >1,000 N

-

Formaldehyde emission : ≤0.05 ppm (CARB Phase 2 compliant)

-

Warranty : 25-year residential, with moisture barrier underlayment included

Urban Loft Series fits condo and apartment projects. You get concrete-look and stone-effect planks in 7mm profiles. These reduce floor height changes. Performance data : impact resistance >1,500 N , stain resistance Class 4 (ISO 26987), castor chair rating Pass (EN 425).

Commercial Collections (AC5)

ProTech Line serves retail, office, and hospitality distributors. Thickness 12mm with beveled edges. Wear layer AC5 certification means >6,500 revolutions (Taber test) before you see wear. Key specs:

-

Load capacity : 450 kg/m² static load

-

Slip resistance : R10 rating (DIN 51130)

-

Fire classification : CAN/ULC-S102 Class C

-

Sound reduction : IIC rating 67-72 with attached underlayment pad

-

Janka hardness : Surface resistance >4,000 N

Technical Documentation Package

Every shipment includes province-ready paperwork. You get bilingual installation guides (English/French per Quebec requirements). Also included: MSDS sheets , VOC emission reports (<10 μg/m³ total), warranty certificates with batch traceability codes, and maintenance specifications (cleaning pH range 6-8, no wax-based products). Need files for your compliance audit? They organize by SKU with QR code scanning for quick digital access.

Design, Collections & Market Fit for Canada

Baier’s design teams analyze what sells in Canadian homes and commercial spaces —not what’s trending in Shanghai showrooms. Our laminate flooring manufacturer process starts with regional buying data. We track what distributors move fastest across different provinces. Then we develop collections that match those demand patterns.

Regional Design Preferences & Collection Mapping

Western Canada (BC, Alberta, Saskatchewan) prefers wide-plank formats (193-196mm width). Natural oak and walnut visuals dominate here. Our Mountain Ridge Collection targets this market. You get 12mm thickness, medium-tone wood grains, and rustic wire-brushed textures. Alberta’s +13.2% retail growth in similar products proves one thing. Buyers want authentic wood looks without maintenance headaches.

Eastern provinces (Ontario, Quebec) split into two patterns. Ontario buyers lean toward contemporary grey-washed oak and light maple finishes. Our Metro Fusion Series answers this. It features 8mm profiles in cool tones—perfect for Toronto and Ottawa’s condo market. Quebec requires stricter bilingual labeling. But design-wise, Montreal distributors report steady sales in herringbone-pattern laminates and European-style narrow planks (120-140mm). Our European Classic Line addresses this niche. It offers 10mm chevron designs and matte finishes.

Atlantic provinces watch their budget but won’t sacrifice appearance. The Coastal Essential Collection offers AC3-rated planks at entry-level pricing. Visuals stay current—light beachwood, driftwood grey, soft pine. Cost per m² runs 15-20% below premium lines. You still get CARB Phase 2 compliance and 20-year warranties.

Commercial Project Fit

Your laminate flooring orders for commercial jobs need different performance data. Baier’s ProTech Commercial Range matches what Canadian architects specify. We monitor commercial flooring specs from major projects. Retail chains, office towers, senior living facilities. Three performance tiers cover 90% of project requirements:

-

Tier 1 (Light Commercial) : Medical offices, boutique retail—AC4 rating, 10mm thickness, 15-year warranty

-

Tier 2 (Moderate Commercial) : Chain restaurants, hotel corridors—AC5 rating, 12mm thickness, warranty coverage includes moisture damage from cleaning protocols

-

Tier 3 (Heavy Commercial) : Shopping mall zones, airport terminals—AC6 rating, 12mm+ thickness with reinforced locking system, certified for rolling load traffic (ISO 4918)

Each tier ships with LEED v4 contribution documentation . This helps contractors earn points under Materials & Resources credits. Indoor air quality test reports show TVOC emissions <100 μg/m³ at 24 hours post-installation. That’s well below CAN/CGSB requirements.

Trend Response & Collection Updates

Canadian fashion and interior design trends shift fast. Faster than 12-month product cycles allow. We run bi-annual collection refreshes instead of annual catalogs. Soft neutrals and earth tones dominate right now (2025 data confirms this). Our design team releases coordinating flooring palettes within 90 days. Recent additions include warm taupe oak and terracotta-undertone walnut visuals. Both align with the earthy color preferences retailers report across women’s and men’s apparel categories.

Textured finishes also follow broader consumer preferences. The 2025 shift toward textured fabrics in Canadian fashion creates flooring demand for embossed-in-register (EIR) surfaces . Our manufacturing line upgraded to synchronized pressing technology . Texture depth matches wood grain patterns within ±0.15mm tolerance. The result? Visuals that read authentic under LED lighting. This matters for high-end residential sales. Buyers compare samples against hardwood alternatives.

Market-Specific Customization Options

Private label programs let Canadian distributors build brand equity. No factory ownership risks. Minimum order quantities start at 3,000 m² for custom colorways within existing embossing patterns. Need proprietary designs? 5,000 m² unlocks custom visuals with exclusive distribution rights for your region. We provide marketing asset packages . professional photography, 3D room renderings, sample boxes with your branding.

Packaging customization addresses practical distribution needs. Bilingual carton printing comes standard (English/French per Quebec regulations). Provincial compliance marks print on packaging. No secondary labeling needed at your warehouse. Pallet configurations adjust for different truck sizes. Standard 1,200mm × 1,000mm for long-haul transport. Or compact 1,000mm × 800mm for urban delivery zones with tight loading docks.

Regional inventory strategies also benefit from our pre-positioned stock program . High-velocity SKUs (8-12 core designs representing 60-70% of sales) can ship from our Vancouver consolidation point. This cuts lead times from 45-60 days (container from China) down to 5-7 days for Western Canada orders. Your cash flow improves. You’re not financing 90-day inventory cycles for proven bestsellers.

OEM / ODM & Private Label Services

You can build your own flooring brand. No factory ownership needed. No million-dollar equipment required. Baier’s OEM/ODM programs turn your brand vision into retail-ready products. We handle the manufacturing side. The global private label market hit $915.1 billion in 2024 and tracks toward $1.62 trillion by 2034 (CAGR 5.9%). Canadian distributors tap this growth. You avoid the capital risks of running production yourself.

Private Label Manufacturing Economics

Your margins jump right away. Manufacturing costs run 40-50% lower compared to sourcing national brands. This translates to gross margins 25-30% higher on your branded products. Take a mid-sized distributor moving 50,000 m² each year under private label. They see $75,000-$125,000 additional gross profit versus reselling manufacturer brands. Consumer acceptance? Not a barrier anymore. 80%+ of U.S. consumers (Canada shows similar patterns) now rate private label quality equal to or better than national brands. 71% of Gen Z buyers choose private label alternatives. Your younger customers expect quality house brands.

Custom Development Process

We structure OEM/ODM partnerships in four tiers. Pick based on your market position:

-

Tier 1 (Quick Launch) : Select from 200+ existing designs. Add your branding. Include custom packaging. MOQ 3,000 m² , 90-day delivery. Best for testing private label viability.

-

Tier 2 (Visual Customization) : Modify colors and textures within our embossing library. MOQ 5,000 m² , 120-day timeline. Your design team works with ours on unique colorways.

-

Tier 3 (Full Custom Development) : Get exclusive visuals. Choose unique embossing patterns. Set performance specs for your market. MOQ 10,000 m² , 150-day development cycle.

-

Tier 4 (Strategic Partnership) : Multi-collection programs with dedicated production capacity. Shared R&D for trend development. Co-branded marketing assets. Annual volume commitments starting 100,000 m² .

Brand Protection & Market Exclusivity

We guarantee regional exclusivity for Tier 3 and Tier 4 partnerships. Your custom designs won’t appear in competitor warehouses across Canada. Legal agreements cover IP protection for unique visuals and performance combinations. Marketing support includes professional photography, 3D room renderings, sample programs, and installation training materials. All branded for your business.

Retailer Growth Through Store Brands

Canadian retailers now view private labels as their #1 growth driver . The shift mirrors U.S. data where store brands grew +3.7% in 2025 versus national brands at +1.1% . Independent flooring retailers compete against big-box chains. They offer exclusive products customers can’t comparison shop online. Your laminate flooring manufacturer partnership with Baier builds this edge. You skip the production headaches.

Quality, Certifications & Environmental Compliance

Canadian regulators set firm rules on formaldehyde limits and fire ratings. Your laminate flooring containers pass CBSA inspection or face detention fees. Baier runs ISO 9001:2015-certified production lines because missing documents cause import failures. We work with third-party labs across North America. Your shipments arrive with current test reports—not certificates that expired 18 months ago.

Manufacturing Quality Systems & Process Controls

We follow ASQ (American Society for Quality) standards that North American buyers trust. Production supervisors hold CQE (Certified Quality Engineer) credentials. This ASQ certification requires 165 questions over 4.5 hours. You need 550/750 points to pass. Factory floor managers complete CSQP (Certified Six Sigma Professional) training. These credentials aren’t just for show. They deliver real results: defect rates <0.3% across production runs, rework cycles reduced 68% since 2022, and customer complaints resolved within 48 hours for 94% of cases.

We monitor seven key parameters every production shift:

– Core density variance (target ±15 kg/m³)

– Formaldehyde emission levels (≤0.04 ppm across batches)

– Wear layer adhesion strength (minimum 1.2 N/mm²)

– Moisture content (7-9%)

– Size tolerance (length ±0.2mm, width ±0.15mm)

– Locking system tensile strength (>1,000 N per joint)

– Surface finish uniformity (gloss variance <5 units)

Sensors catch problems before bad planks reach packaging. Your containers ship with batch codes. Problems show up after install? We trace them back to exact production hours.

North American Environmental Certifications

CARB Phase 2 compliance is required for California shipments. Canada expects it too. Our formaldehyde emissions test at ≤0.05 ppm (ASTM E1333 chamber method). That’s 50% below the 0.09 ppm CARB Phase 2 limit. TSCA Title VI certification covers US-bound shipments through the same distributor networks. FloorScore certification (SCS Global Services) shows total VOC emissions <10 μg/m³. Health Canada’s air quality guidelines allow 50 μg/m³ for homes.

Fire safety docs include CAN/ULC-S102 Class C ratings for surface burning. Commercial-grade collections meet ASTM E648 Critical Radiant Flux requirements (Class I: ≥0.45 W/cm²) for corridors and exit routes. Your architects ask for these ratings. We send the lab reports with every shipment.

Manufacturing Capabilities & Supply Reliability

Baier’s factory runs 340+ production days each year with 95.8% on-time delivery (OTD) across 2024 shipments to Canadian buyers. This number matters. Industry benchmarks set 95% OTD as the minimum for reliable manufacturing partnerships. We calculate this metric clearly: orders delivered on or before the promised date divided by total orders shipped, times 100. Your containers leave our facility on schedule. No last-minute delays that disrupt your warehouse schedules or retail commitments.

Production Capacity & Throughput

Our laminate flooring manufacturer systems process 850,000 m² each month across three production lines. Peak capacity hits 1.1 million m² during spring installation season demand spikes. Lead times stay predictable:

-

Stock collections : 15-20 days from PO to container loading

-

Custom colorways (existing patterns) : 35-45 days with sample approval

-

Full custom development : 90-120 days with three prototype rounds

Inventory turnover ratio sits at 7.2 per year. This fits the healthy 5-10 range that shows efficient restocking without cash stuck in slow-moving stock. We track sales speed by SKU. Fast-movers restock every 45 days. Slower designs get smaller runs to avoid old inventory.

Order Accuracy & Fulfillment Metrics

Perfect Order Rate (POR) reached 97.3% in 2024. Orders fulfilled without quantity errors, damage, or wrong SKUs. Each shipment goes through five-point verification before we seal containers:

Quantity count : Automated pallet scanners check carton counts against packing lists

SKU matching : Barcode validation confirms design codes match PO specs

Quality inspection : Random carton sampling (3% of total volume) for surface defects

Documentation check : Certificates, test reports, commercial invoices bundled in waterproof packaging

Loading photography : Timestamped images of container interiors before door seal

Canadian importers report <2% claims on Baier shipments. Compare that to 8-12% industry averages for Asian flooring manufacturers. Lower claims mean fewer charge-backs cutting into your margins.

Supply Chain Resilience & Risk Mitigation

We maintain dual-source agreements for critical raw materials. HDF core suppliers? Three qualified vendors across different regions. Overlay paper? Two primary sources plus backup capacity. This spread follows proven supplier reliability methods. The 2025 Supplier Reliability Index shows North American sectors gained ground on on-time delivery and response from Q1 2023 levels. Late 2024 saw setbacks from global tensions. Baier’s multi-vendor strategy absorbs these shocks.

Real-time tracking systems monitor production status each hour. You log into our client portal. See your order’s progress: materials received, pressing complete, quality passed, packed for shipment. Average order cycle time runs 42 days from deposit to vessel departure. Backorder rate stays below 1.5% . Production planning uses rolling 90-day demand forecasts. Your repeat orders create forecast data that reserves capacity.

Logistics, Commercial Terms & Export Support for Canada

Container freight from China to Canadian ports takes 45-60 days under normal conditions. Add customs clearance and inland trucking to your warehouse. You’re looking at 70+ days from factory gate to retail floor. Baier structures logistics partnerships that cut delays. We reduce landed costs for laminate flooring manufacturer shipments bound for Canadian importers and distributors.

Ocean Freight & Port Routing Strategy

West Coast routing through Vancouver handles most of our Canadian shipments. Transit time from Ningbo/Shanghai averages 18-22 days to Vancouver terminals. We consolidate LCL (less-than-container-load) orders for smaller importers. Your 3,000 m² test order shares container space with other non-competing cargo. Cost savings run 35-40% versus booking a full 40HQ container yourself.

East Coast options through Halifax or Montreal add 10-14 days transit. But they serve Atlantic provinces and Quebec better. Total ocean time: 30-35 days . Inland trucking from Vancouver to Toronto costs CAD $3,200-$3,800 per container . Direct Halifax delivery cuts that expense. This matters if your distribution center sits east of Ontario.

Freight rate structures include:

– FOB (Free On Board) : You arrange ocean freight and insurance. Best for established importers with carrier contracts.

– CIF (Cost, Insurance, Freight) : Baier books shipping to named Canadian port. You handle customs clearance and inland delivery.

– DDP (Delivered Duty Paid) : We manage the full chain to your warehouse door. This works well for first-time importers testing Canadian market entry.

Cross-Border Trucking & Last-Mile Delivery

Trucking carries over 60% of surface trade between Canada and the U.S. The same road networks distribute containers from Vancouver or Montreal to interior provinces. March 2025 data shows US$67.5B in truck trade with Canada alone. Baier partners with bonded carriers holding CSA (Customs Self-Assessment) program status. These carriers clear CBSA inspections 40% faster than non-certified trucking companies.

Delivery timelines from port to major distribution hubs:

– Vancouver → Calgary: 2-3 days (950 km)

– Vancouver → Toronto: 4-5 days (4,400 km)

– Halifax → Montreal: 1-2 days (1,280 km)

– Montreal → Toronto: 1 day (540 km)

Q4 2024 Canadian truckload market saw December loads up 18% year-over-year . Cross-border shipments represented ~⅔ of all loads . Capacity tightened in late January 2025. Shippers pulled freight forward ahead of expected U.S. tariffs. Tender rejection rates for outbound Canada peaked at 3.8% . Then they fell when tariffs got delayed. Our pre-booked carrier agreements locked rates during this chaos. Your containers moved while spot-market shippers faced 15-25% rate spikes .

Payment Terms & Working Capital Solutions

Standard terms for new Canadian importers start at 30% deposit, 70% against copy of B/L (Bill of Lading) . After three successful shipments, we extend Net 30 terms from B/L date. Established distribution partners with 100,000+ m² annual volume qualify for Net 60 payment windows. This protects your cash flow during the 45-60 day ocean transit period.

Letter of Credit (L/C) options work for importers needing bank-backed payment security. We accept irrevocable L/Cs from major Canadian banks (RBC, TD, Scotiabank, BMO, CIBC). Sight L/C requires payment upon document presentation. Usance L/C (30-90 days) provides extended terms with bank guarantee. Processing adds CAD $800-$1,200 in bank fees per container. But it removes payment disputes.

Trade finance programs through our logistics partners offer inventory financing at 6.5-8.5% annual rates . You pay 15-20% upfront . The finance company covers the balance. They get repaid as you sell inventory over 90-180 days. This keeps working capital free for marketing and sales investment. No need to lock it in container deposits.

Export Documentation & Certification Packages

Every Baier shipment includes a complete export documentation set . We organize it in waterproof packaging:

Commercial documents:

– Commercial invoice (3 originals, 5 copies) with HS code, unit pricing, payment terms

– Packing list detailing carton counts, m² per SKU, gross/net weights, pallet numbers

– Bill of Lading (ocean B/L or truck waybill for inland points)

– Certificate of Origin (non-preferential; China origin declared)

– Insurance certificate (if CIF/CIP terms)

Compliance certificates:

– CARB Phase 2 formaldehyde test reports (ASTM E1333 method) from accredited labs

– TSCA Title VI certification (for distributors serving U.S. markets from Canadian warehouses)

– FloorScore indoor air quality certificates

– Fire safety ratings (CAN/ULC-S102 Class C; ASTM E648 for commercial grades)

– Product warranties with batch traceability codes

Technical documents:

– Installation guides (bilingual English/French per Quebec regulations)

– Maintenance specifications and cleaning product compatibility charts

– MSDS (Material Safety Data Sheets) for adhesive-backed underlayment or attached pads

– VOC emission reports showing total volatile organic compounds <10 μg/m³

Digital access system: All documents upload to our cloud portal with QR code links printed on carton labels. CBSA officers scan codes for instant certificate verification. Average clearance time: <45 minutes versus 4-8 hours for manual document review. Your containers release faster. Demurrage fees (CAD $150-$200 per day) stay minimal.

Container Loading & Damage Prevention

Standard 40HQ containers (40-foot high-cube) hold 2,200-2,600 m² . This depends on plank thickness and packaging method. 8mm collections max out near 2,600 m² . 12mm commercial-grade planks fit ~2,200 m² . We optimize pallet stacking patterns to use full container height (2.69m internal).

Loading protocol follows seven-step damage prevention :

1. Container inspection : Pre-load survey for moisture, structural damage, residual odors

2. Moisture barrier : Desiccant bags (1 kg calcium chloride units) placed at floor level and ceiling— 12-16 bags per container based on transit duration

3. Pallet base layer : Anti-slip mats prevent load shifting during ocean transport

4. Vertical stacking : Pallets secured with stretch film + corner boards + cargo straps rated for 2,500 kg tension

5. Weight distribution : Heavier SKUs load toward container front; lighter toward door end for unloading safety

6. Interior bracing : Airbags inflated between last pallet row and container doors—absorbs road shock

7. Photo documentation : Timestamped images of load process uploaded to your shipment file

Damage claims on Baier shipments run <1.2% versus 5-8% industry averages for flooring imports. Lower claims mean fewer charge-backs, replacement shipments, and customer disputes eating your margins.

Multi-Province Distribution Support

Canada’s interprovincial trade barriers cost the economy CAD $130B each year ( ~6.9% of GDP ). Regulatory differences between provinces add friction. Baier reduces this through province-ready packaging :

Bilingual labeling (English/French) printed on cartons—meets Quebec’s Bill 101 consumer protection requirements

Provincial compliance marks showing applicable fire ratings, environmental certs, building code references

Regional installation guides addressing province-specific subfloor prep, moisture barrier rules, expansion gap requirements

Alberta’s building codes differ from Ontario’s OBC (Ontario Building Code) on underlayment specs for apartment buildings. Our installation guides reference the correct standards by province. Your installers don’t cross-check regulations mid-job.

Consolidated shipping documentation works across all provinces. One set of compliance certificates covers sales from BC to Newfoundland. No need to repackage or relabel once trucks cross provincial lines. This saves 15-20 hours per shipment in warehouse labor. Compare that to manufacturers requiring province-specific prep.