A Practical Guide by Core Board Type

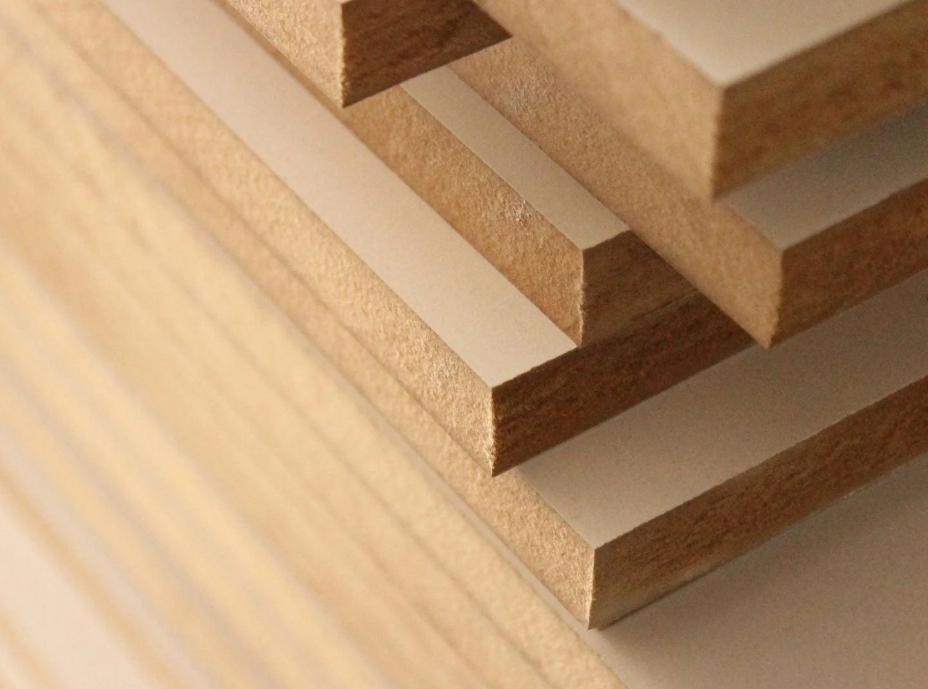

Furniture boards are not defined by surface finishes alone.

Behind every cabinet door, wardrobe panel, or appliance cover lies a core board that determines strength, screw holding, moisture behavior, dimensional stability, and long-term service life.

In professional furniture manufacturing—kitchen cabinetry, built-in storage, hotel casegoods, and home appliances—the choice of board material is a technical and economic decision, not just a visual one. While laminates and veneers shape appearance, the core board governs performance during fabrication, installation, and daily use.

This guide explains the most commonly used wood-based furniture boards, how they perform in doors, cabinets, and appliance covers, and where each material delivers the best balance of durability, cost, and manufacturability.

Furniture Boards by Core Board Type

Every cabinet and wardrobe needs a strong core board. Pick the wrong one, and your beautiful finish won’t hide the weakness inside.

Last summer, I toured a custom kitchen shop in Berlin. MDF cut through the CNC machine smoothly. It created perfect door curves that particle board just can’t match. But the engineer showed me something different. Plywood holds screws better. This matters when you hang heavy appliance covers. About 67% of high-use kitchens switch to plywood for this reason, despite the higher cost.

Steamy dishwashers and fingerprints test your furniture constantly. The right core board protects your investment. It’s not just wood—it’s what keeps your furniture strong for years.

MDF Furniture Boards

MDF Furniture Boards: Precision, Surface Quality, and Design Flexibility

Walk into a modern kitchen showroom. The smooth cabinet doors, seamless painted panels, and perfectly profiled edges are most likely built on Medium Density Fiberboard (MDF).

MDF is engineered from fine wood fibers bonded under pressure, resulting in a uniform, void-free internal structure. This homogeneity makes MDF exceptionally stable for furniture components that demand clean finishes and tight tolerances.

In furniture systems, MDF functions primarily as:

A paint-grade door core

A lamination and veneer substrate

A dimensionally consistent panel for CNC machining

Its lack of grain direction eliminates warping caused by natural wood movement, which directly improves surface quality and edge precision.

Why MDF Is Widely Used in Furniture

From a manufacturing perspective, MDF offers several advantages:

Surface consistency: No knots or grain telegraphing under paint or foil

Machinability: Reliable CNC routing, edge profiling, and drilling

Finish efficiency: Lower defect rates in painted and laminated doors compared to particle board

These characteristics make MDF the default choice for furniture doors and visible panels where appearance is critical.

Typical Furniture Applications

MDF furniture boards are commonly used in:

Cabinet doors and drawer fronts

Wardrobe and storage furniture panels

Appliance front panels and decorative covers

Limitations & Design Considerations

Moisture sensitivity unless MR-grade MDF is specified

Edge sealing is essential for long-term durability

Not suitable for load-bearing furniture components

Industry Insight:

For furniture components prioritizing surface quality and design flexibility, MDF remains the most production-efficient solution.

Plywood Furniture Boards

Role of Plywood in Furniture Systems

Plywood serves a different role in furniture construction—strength and structural reliability.

Built from cross-laminated veneers, plywood delivers superior bending strength and screw holding compared to MDF and particle board. This makes it especially valuable in furniture components subjected to repeated loading or mechanical stress.

Why Furniture Manufacturers Choose Plywood

Key performance advantages include:

High dimensional stability across wide panels

Excellent fastener retention for hinges and hardware

Better moisture tolerance when exterior or MR grades are used

These properties make plywood suitable for furniture components that must support weight or withstand frequent use.

Typical Furniture Applications

Plywood furniture boards are widely used in:

Cabinet carcasses and structural frames

Shelving systems and load-bearing panels

Appliance housings requiring strength and rigidity

Limitations & Design Considerations

Higher material cost compared to MDF and particle board

Requires veneer or overlay for premium surface finishes

Heavier panels may affect handling and installation

Industry Insight:

Plywood is chosen when furniture performance and longevity outweigh pure surface aesthetics.

Particle Board Furniture Panels

Role of Particle Board in Furniture Manufacturing

Particle board is the most cost-optimized furniture board, widely used in standardized furniture systems and mass production.

Manufactured from wood particles bonded with resin, it provides a flat, consistent panel suitable for surface decoration, though with lower internal strength than MDF or plywood.

Why Particle Board Remains Popular

Particle board continues to be widely specified because of:

Cost efficiency in large-scale furniture production

Compatibility with melamine-faced panels

Uniform panel thickness for modular systems

In controlled indoor environments, it delivers reliable performance at a lower cost point.

Typical Furniture Applications

Particle board furniture panels are commonly used in:

Cabinet bodies and internal partitions

Flat-pack furniture and modular storage systems

Appliance covers with low structural demands

Limitations & Design Considerations

Lower moisture resistance

Reduced screw holding strength

Edge protection is critical

Industry Insight:

Particle board is best suited for cost-driven furniture projects with standardized designs and controlled usage conditions.

OSB Furniture Panels

Role of OSB in Furniture Applications

Oriented Strand Board (OSB) occupies a design-driven niche in furniture board applications.

Rather than concealing its structure, OSB embraces its exposed strand pattern as a deliberate visual feature, making it suitable for furniture designs that prioritize material honesty and industrial aesthetics.

Why Designers Choose OSB

OSB furniture panels are selected for:

Raw, industrial visual language

Strong panel stiffness at relatively low cost

Distinctive texture that replaces decorative finishes

Typical Furniture Applications

OSB furniture boards are used in:

Industrial-style cabinets and shelving

Furniture for creative studios and retail spaces

Feature furniture pieces and display systems

Limitations & Design Considerations

Not suitable for refined or high-gloss finishes

Moisture protection and sealing required

Design appeal is project-specific

Industry Insight:

OSB furniture boards work best when structure itself becomes part of the design expression.

Comparative Overview (Furniture Use Focus)

| Board Type | Surface Quality | Structural Strength | Moisture Tolerance | Cost Level | Typical Furniture Use |

|---|---|---|---|---|---|

| MDF | Excellent | Low | Low–Medium | Medium | Doors, fronts, decorative panels |

| Plywood | Good | High | Medium–High | High | Carcasses, shelves, appliance housings |

| Particle Board | Moderate | Low | Low | Low | Cabinet bodies, modular furniture |

| OSB | Raw / Textured | Medium | Low–Medium | Low–Medium | Design-led furniture |

Conclusion: Choosing the Right Furniture Board

Furniture performance begins with core board selection.

While surface finishes define appearance, core materials determine durability, machinability, and long-term reliability.

Choose MDF for high-quality furniture doors and decorative fronts

Choose plywood for strength-critical furniture components

Choose particle board for cost-sensitive, standardized furniture systems

Choose OSB when material expression defines the design

Understanding these differences allows furniture manufacturers, designers, and buyers to specify furniture boards that perform reliably—not just look good.