European Flooring Sustainability Models – Comparison Table

|

Brand |

Circular Economy Entry Point |

Core Sustainability Focus |

Key Evidence in Article |

Geographic Strength |

Best-Fit Buyer Profile |

|---|---|---|---|---|---|

|

Baier |

Manufacturing & supply chain |

Waste prevention, process efficiency, scalable recycled inputs |

Closed-loop factory workflows, material yield optimization, export-focused carbon reduction |

Global export markets |

OEM/ODM buyers, distributors, large-volume projects |

|

Parador |

Governance & compliance |

Verified environmental management |

EMAS III certification, annual public environmental reports, 100% certified raw materials |

EU (Germany / Austria) |

Public sector, regulated markets, ESG-led procurement |

|

Classen Group |

Material innovation |

PVC-free, fully recyclable flooring |

NUVA mineral–PP composition, Blue Angel certification, lighter SPC performance data |

Europe |

Health-focused projects, residential & commercial installers |

|

Polyflor |

Vertical market specialization |

Durability & safety in public spaces |

Healthcare & education revenue dominance, NHS and school projects |

UK |

Hospitals, schools, institutional buyers |

|

PROLUXE |

Nearshoring & logistics |

Speed, flexibility, cost efficiency |

2–4 week EU delivery, localized hubs, direct factory supply |

Europe |

Time-sensitive projects, cost-controlled developments |

Baier – Manufacturer-Led Circular Flooring Solutions Built for Global Supply Chains

Baier approaches circular economy from the manufacturing and supply-chain level, not as a marketing add-on. As a flooring manufacturer focused on laminate flooring, SPC, LVT, and underlay systems, Baier integrates material efficiency, waste reduction, and recycled inputs directly into production.

Instead of post-consumer branding programs, Baier’s circular strategy starts inside the factory.

Manufacturing-Based Waste Reduction

Baier operates a closed-loop production workflow across its flooring and underlay lines.

Production offcuts and trimming waste are systematically sorted and recycled back into internal processes

Wood-based panel residues are reprocessed into core-layer and auxiliary materials

Vinyl and polymer scraps are reintegrated where technically feasible, reducing landfill dependency

This approach minimizes waste before products ever leave the factory, which is critical for large-volume export manufacturing.

Carbon Reduction Through Structural Optimization

Baier’s carbon reduction strategy focuses on controllable emission sources:

Raw material sourcing optimization

High-density logistics planning for export containers

Energy efficiency upgrades in pressing, extrusion, and curing processes

Most emissions in the flooring industry occur outside the factory gate—in raw materials, transportation, installation, and disposal.

Baier therefore prioritizes:

Material yield improvement (less waste per m²)

Product durability to extend replacement cycles

Export-ready packaging optimization to reduce emissions per shipped square meter

This manufacturing-led approach aligns with Scope 3 emission reduction logic, which dominates the flooring carbon footprint.

Recycled & Bio-Based Materials at Scale

Baier continuously increases the use of recycled and bio-based inputs, particularly in:

Laminate flooring core layers

SPC / LVT formulations

Acoustic and moisture-control underlay systems

Rather than applying recycled content to niche SKUs only, Baier focuses on scalable product lines suitable for OEM and project supply.

The long-term objective is clear:

Designed for Long Service Life, Not Fast Replacement

Circular economy does not stop at recycling.

Baier designs flooring systems to stay in use longer:

Stable locking systems reduce installation failure

Wear-layer and surface performance support heavy-use scenarios

Compatible underlay systems extend floor lifespan and reduce subfloor damage

Longer service life directly lowers:

Replacement frequency

Installation waste

Lifecycle carbon emissions

A Practical Circular Model for Global Buyers

Unlike Europe-centric take-back programs limited by geography, Baier’s circular strategy is built for global B2B buyers:

OEM / ODM product customization

Stable mass production

Compliance with international environmental standards

Cost-performance balance for emerging and developed markets

Baier’s model reflects the reality of global flooring trade:

Parador – The Single Flooring Company Certified Under EMAS III

No other flooring maker in Europe can match Parador’s credentials. They earned EMAS III certification in 2015. No one else in their industry has this. This isn’t something they gave themselves. The European Union’s toughest environmental standard backs it.

EMAS III beats basic ISO certifications. Public accountability is required. Parador has published a validated environmental report every year since 2016. An outside expert checks and approves each one. The report shows their sustainability plans, specific actions, and real results.

Two Production Sites Under Strict Environmental Control

Parador runs two plants—Coesfeld in Germany and Güssing in Austria. Both hold EMAS III and ISO 14001 certifications. The company puts EMAS key indicators into their ISO 14001 system. This builds a cycle of ongoing improvements.

Their environmental management goes deep. Workers help shape company policies. The program sets clear goals with deadlines. Audits happen inside the company on a regular basis. The yearly public report tracks progress on all metrics.

100% Certified Raw Materials with Local Sourcing

Parador certifies 100% of raw materials. Local wood supplies their Parquet Flooring. Short transport routes lower carbon output from shipping. All other floors and panels use materials you can recycle.

Their certifications cover a lot of ground:

-

FSC® and PEFC chain of custody checks

-

TÜV Rheinland for product quality and safety

-

French interior air quality mark for low emissions (formaldehyde and VOC limits)

-

CE marking under EN 14041 for resilient, textile, and laminate flooring since 2007

Wood suppliers need to meet certification rules. Parador picks certified sources first. They stick to German due diligence rules on wood origin. Risk-minimized sources are the ones that get used.

Engineered Production with Zero-Waste Thinking

Parador’s Factory Production Control tracks every step. Engineered wood flooring uses wood from domestic sources. The top layer comes in three types: untreated, lacquered, or oiled solid wood. A spruce-pine middle layer keeps things stable. The counter layer stops warping. Their Safe-Lock® PRO click system works without glue.

Laminate and modular flooring starts with an HDF Core. PP or PUR wear layers make it last. Cork footfall insulation cuts down noise. Wood dust from cutting stays in the factory. It feeds the heating system. Heat from burning waste wood goes to the local district heating plant. Parador gets process heat for production in return.

Long-Term Value Beyond Installation

Parquet floors store CO2. The wood holds carbon for decades. This cuts greenhouse gas effects while the product lasts. Old floors don’t go to waste. Recyclable materials circle back into new production.

Parador reports under the German Sustainability Code (DNK). They follow Germany’s national Sustainability Act. Every environmental claim ties back to public, checked data.

Classen Group – PVC-Free and Circular Flooring Solutions

Classen Group builds their NUVA flooring line from 60% natural mineral fillers and 40% polypropylene. Most of that polypropylene comes from recycled plastic. You get a 100% recyclable floor. It skips PVC, chlorine, phthalates, and plasticizers.

Their factory in Kaisersesch, Germany, earned the Blue Angel Certificate. This mark confirms energy-smart production. It also confirms strict controls on harmful substances. Every board helps maintain healthy indoor air. No questionable chemicals get released.

Mineral-Reinforced Core Beats Traditional SPC Weight

Traditional SPC flooring feels heavy. Classen’s mineral-reinforced polypropylene core weighs less. Boards are easier to carry. Installation goes faster. Stability stays strong.

Weight drops across different thicknesses:

-

5.94 kg/m² at 4.0mm thickness

-

4.75 kg/m² at 3.2mm thickness

-

3.38 kg/m² at 2.5mm thickness

Each unit weighs about 15kg net. Contractors move more material per trip. DIY installers handle boards with ease.

Water Protection Through Smart Engineering

Water can’t get through the joints. Classen’s megaloc-aqua-protect technology seals the click profile. The water-resistant locking system blocks moisture. It stops before reaching the subfloor.

Their megaloc and easyloc systems work for loose laying. You skip grouting. The micro-joint design looks clean. Kitchens and bathrooms get full protection. No extra steps needed.

Glued installations use CERAMIN Flex technology. Full-surface bonding connects to the subfloor. This improves room acoustics. The 2.5mm height fits tight spaces. You can lay planks in any direction. Gloss differences won’t show.

Four Service Classes from Homes to Factories

NUVA collections cover service classes 32 through 42. That spans residential living rooms to industrial sites. Abrasion classes hit AC5 and AC6. Usage classes include UC34 and UC34/42.

Dimensions fit different project needs:

-

1290 × 203 × 5.5mm plank format

-

1290 × 210 × 2.5mm dryback

-

776 × 387 × 5.5mm tile format

-

595 × 595 × 2.5mm square tile

Select products include built-in 1mm impact sound insulation. All products work with floor heating systems. The material stays stable in size. It resists UV damage. Floors feel warm to touch.

Real Warranties Backed by Performance Data

Residential housing gets 25-year warranties on SPC products. Select lines get 20 years. Public utility buildings receive 5-year coverage on SPC. Other products get 3 years.

Classen states their position: “PVC-free SPC matches traditional SPC—and in several areas, performs better.” The lighter weight backs this claim. So does the superior water protection. Plus, the recyclable materials deliver measurable results.

Polyflor – UK-Based Specialist in Vertical Market Flooring Solutions

Polyflor hit £126 million (USD 160 million) in healthcare and education flooring revenue alone. That’s one segment. One maker. One base near Manchester.

The company celebrates its 100th year of UK production in 2025. They started making homogeneous vinyl flooring in the 1950s. Now they lead commercial vinyl through focused vertical market work. Hospitals, schools, care homes, and offices power their business.

Revenue Focus on Public Sector Projects

Total revenue sits at USD 99.2 million each year across all markets. UK sales reached £110.7 million in 2024. That dropped 4.4% from £117.5 million in 2023. But public sector pipelines keep growing.

281 employees run operations. The team works on six core areas:

-

Healthcare sites and NHS contracts

-

Specialist care homes for older and disabled people

-

Education sites from primary schools to universities

-

Office buildings and corporate headquarters

-

Leisure centers and sports sites

-

Social housing projects

Government programs boost demand. The NHS New Hospital Programme brings multi-year flooring contracts. National school rebuilding does the same. These aren’t one-off jobs. They bring steady income with repeat orders.

Market Growth in Resilient Flooring

The UK floor covering market hit USD 4.46 billion in 2025. It’s expected to reach USD 5.37 billion by 2030. Resilient flooring grows fastest at 6.12% CAGR from 2024 to 2030.

Public-sector updates add +0.6% to that growth rate. Big projects need tough, quick-install options. Polyflor offers:

-

Polysafe safety flooring for slip resistance

-

Luxury vinyl tiles with realistic looks

-

Heterogeneous and homogeneous vinyl styles

-

Acoustic flooring choices for noise control

LVT shows the strongest growth. UK searches hit 55,000 each month for “LVT flooring” and 74,000 for “vinyl flooring.” Year-over-year trends show +14% for LVT and +22% for LVT click systems. Vinyl holds 28.3% of the global flooring market in 2024.

Distribution Through Specialist Channels

Big-box and specialist retailers control 66.65% of UK market sales in 2024. That channel grows at 5.31% through 2030. Polyflor competes with Kent Blaxill, FAKRO GB, and Thomas Dudley. Their vertical market know-how sets them apart.

Home spending makes up 64.51% of UK floor covering costs. It grows at 4.56% CAGR. But Polyflor stays focused on commercial and institutional buyers. Healthcare and education alone show that focus pays off.

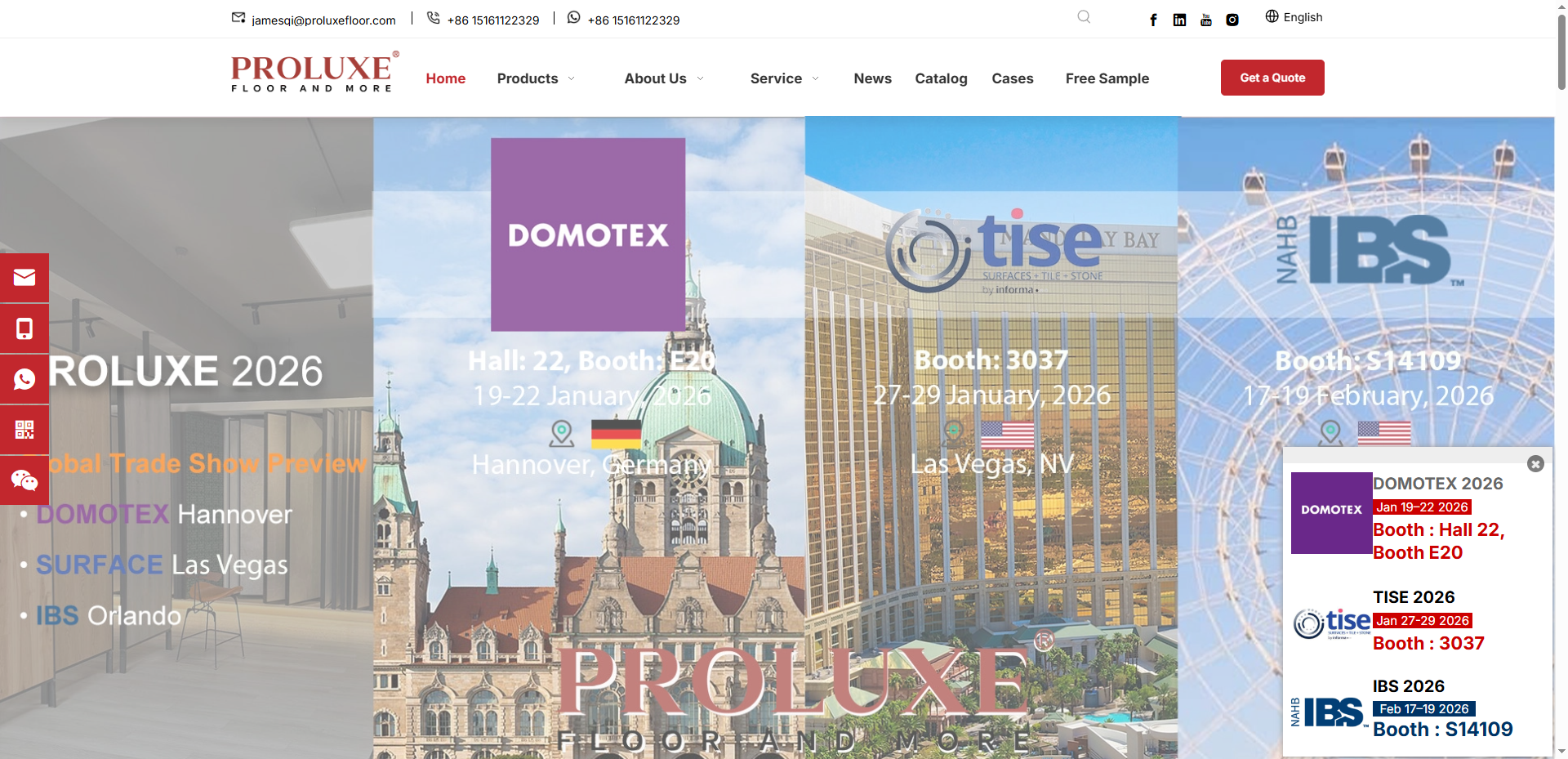

PROLUXE – Fast Lead Times Through Local European Manufacturing

PROLUXE ships flooring orders across Europe in 2-4 weeks. That’s months faster than the industry norm. Local delivery cuts the wait between your order and install.

The company runs factories in China, Vietnam, and Thailand. All production meets European standards for strength and appearance. Speed comes from their hubs in Spain, Poland, and Portugal. These points keep stock near your project sites.

Production Scale Meets Custom Flexibility

PROLUXE handles orders from 1,000 m² to 100,000 m². Modern production lines process high volumes fast. Small home jobs get the same care as big commercial contracts.

Custom work doesn’t slow things down. Clients specify designs. They pick special wear layers for specific markets. The factory adapts. 20 years of SPC manufacturing backs this flexibility.

SPC wall panels work the same way. Stable capacity supports large orders. Custom specs work for unique projects. Lead times stay sharp across both product types.

Direct Delivery Cuts Costs by 30%

PROLUXE skips traditional distributor chains. Direct factory delivery to European markets drops costs by 30% versus local suppliers. Your project budgets stretch further without sacrificing quality.

Here’s how eco-friendly Lvt & Lvp Brands In Europe compare on delivery speed:

|

Aspect |

PROLUXE (Localized EU Delivery) |

Traditional Global Sourcing |

|---|---|---|

|

Lead Time |

2-4 weeks |

3-6 months standard |

|

Order Range |

1,000-100,000 m² |

Limited flexibility |

|

Cost Savings |

30% vs. local suppliers |

Standard pricing |

Nearshoring Edge in Fast-Moving Markets

EU nearshoring puts PROLUXE closer to customers. Close proximity means faster response to design trends. Architects and contractors get new styles fast. Distant sourcing can’t match this speed.

Distribution centers in Spain, Poland, and Portugal serve different regions. Southern Europe pulls from Spain. Central and Eastern projects ship from Poland. Portugal handles Atlantic-facing markets. The network keeps transit times short across the continent.

EU Core Environmental Certification Comparison Framework

The European Union rolled out unified carbon removal rules in 2024. The EU Carbon Removal Certification Framework (CRCF) ended years of broken standards across member states. Before this, dozens of schemes operated with different definitions. Double counting was common. Greenwashing hurt market trust. The CRCF fixes that.

This voluntary scheme sets one standard for certifying carbon dioxide removal activities. It supports the EU’s climate neutrality target for 2050. flooring manufacturers who capture and store carbon now follow the same quality rules. This applies whether they operate in France, Germany, or Poland.

Four Quality Principles Every Manufacturer Must Meet

The CRCF built its quality standards around QU.A.L.ITY criteria. Every carbon removal activity needs to pass four tests:

Quantification requires accurate CO₂ measurement. You can’t estimate or guess. Operators calculate the exact “net carbon removal benefit” using strong methods. The numbers must be clear. They must be verifiable.

Additionality means going beyond normal practice. Your carbon removal work must exceed legal requirements. Standard baselines reflect current regulations and market conditions. The EU updates these baselines often. You can’t claim credit for what you already have to do.

Long-term Storage tracks how long CO₂ stays locked away. The framework calculates storage periods. Short-term capture doesn’t count. Carbon needs to stay out of the atmosphere for years or decades.

Sustainability protects the environment while removing carbon. Activities must respect biodiversity. They follow zero-pollution goals. They “do no significant harm to the environment.” Plus, they contribute to at least one EU sustainability objective.

Certification Steps and Public Tracking

Operators sign up through approved certification schemes. The European Commission validates each scheme. Independent third-party bodies then evaluate your compliance. They check against the four quality criteria.

Certificates stay valid until the next audit. Most operators get recertified each year. Some go five years between checks. Carbon removal units get issued after approval. Public registries track every unit.

EU-based activities qualify. Your factory, forest, or farm must sit inside Union borders. This keeps verification standards tight. It keeps them consistent.

Who Can Earn Carbon Removal Credits

Farmers and land managers lead the way. Forest management activities qualify. Biogenic CO₂ operators participate too. Green LVT & LVP brands in Europe that store carbon in products can track their work through Energy Performance Certificates.

Small operators don’t get left behind. Group auditing works for small farmers and forest holders. This cuts certification costs. It maintains quality standards.

The framework uses remote sensing, modeling, and on-site measurements. Links with other EU information systems keep monitoring costs down. Standard baselines make verification faster.

Market Integration and Compliance Options

Certified units serve multiple purposes. You can use them for compliance under EU climate regulations. That includes the EU ETS, Effort Sharing Regulation, and LULUCF Regulation. Units fit into EU Determined Contributions too.

Voluntary carbon market trading remains an option. Companies buy credits to meet internal climate goals. EU and national removal targets create another demand source.

A unified European registry launches soon. It prevents double counting across the Union. Until then, certification schemes run compatible public registries. Audit summaries and compliance certificates get recorded there. Every transaction stays transparent.

Quality Fixes After Initial Concerns

Analysis in November 2024 found problems with draft methods. The first versions risked creating low-quality units. This could undermine EU climate efforts. The Commission responded fast. Revised methods appeared in March-April 2025. Expert Group feedback shaped the updates. More refinements continue through end of 2025.

Conclusion

Across Europe’s flooring industry, sustainability has moved beyond slogans and into operational structure, material science, and delivery models.

The brands discussed in this analysis demonstrate that there is no single circular economy formula, but rather multiple execution paths shaped by history, regulation, market focus, and supply-chain reality.

Baier represents a manufacturer-led circular model, where waste reduction, recycled inputs, and carbon control are engineered directly into factory processes. This approach prioritizes scalability, export efficiency, and global supply-chain compatibility over geography-limited take-back schemes.

Parador exemplifies a governance-driven sustainability model, anchored in EMAS III certification, public accountability, and fully certified raw materials. Its strength lies in verified compliance, long-term transparency, and public-sector credibility.

Classen Group proves that material innovation can redefine category standards, delivering PVC-free, fully recyclable flooring that matches or exceeds traditional SPC performance while reducing weight and improving indoor air quality.

Polyflor shows how vertical market specialization—particularly in healthcare and education—creates sustainability through durability, safety, and long product life cycles rather than frequent replacement.

PROLUXE highlights a nearshoring and speed-to-market model, where localized European delivery, flexible production, and direct supply chains reduce lead times, indirect emissions, and total project costs.

Taken together, these cases point to a clear industry reality:

Sustainable flooring is no longer defined by a single certification or claim, but by how effectively circular principles are embedded into manufacturing, materials, governance, and delivery.