What Is SPC Flooring?

Stone Plastic Composite (SPC) flooring mixes natural limestone powder with virgin PVC. This creates a rigid core vinyl product. The formula uses 70% natural stone materials mixed with 30% virgin PVC, minerals, and stabilizers. This produces a core density between 2100-2200 kg/m³. That’s much denser and more stable than standard LVT flooring.

The rigid core structure sets SPC apart. It won’t flex under pressure like traditional vinyl planks. You get resistance against dents, scratches, and impacts. These would damage softer flooring types. The material stays flat. No warping or swelling happens with moisture exposure.

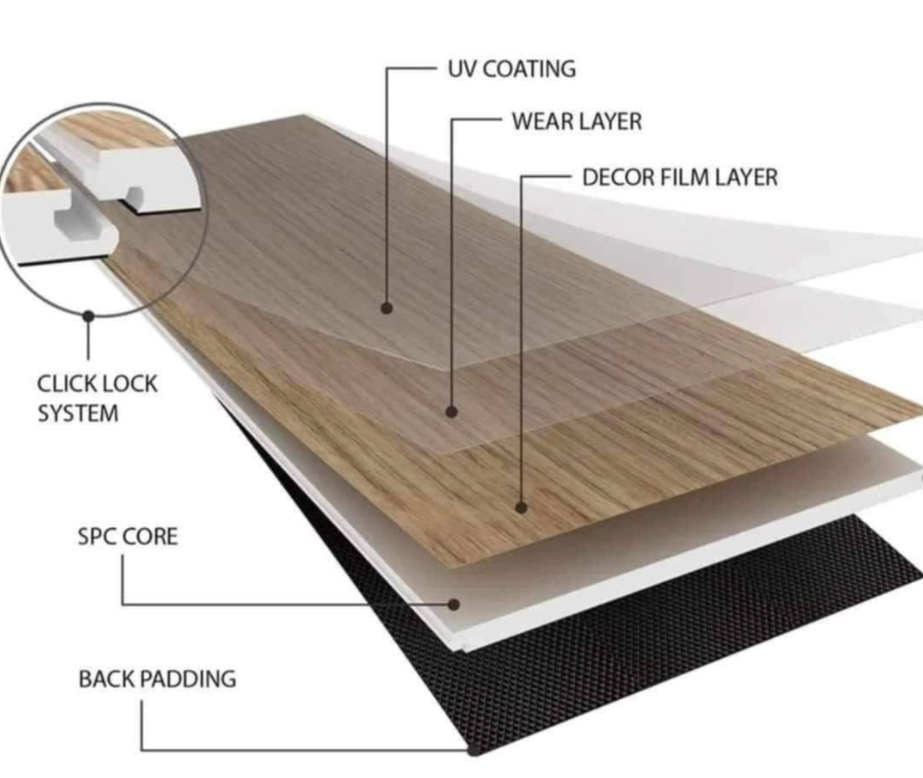

The Multi-Layer Construction

SPC flooring stacks several functional layers:

UV wear layer (0.2-0.7mm thick) – protects against fading

Transparent vinyl wear layer – guards the surface from wear

Decorative vinyl film – displays wood grain or stone patterns

Rigid SPC core (4.5 mils thick) – provides structural stability

Optional underlayment – IXPE (1.5mm), EVA, or cork padding for sound dampening

Dimensions range from 1220x180mm to 1820x228mm. Total thickness varies between 3.5mm and 9.5mm. 5.5mm is a popular choice. The wear layer measures 0.3mm to 0.5mm thick.

Performance Specs That Matter

The material achieves 100% waterproof status. This comes from its stone-plastic composition. High-traffic areas? No problem. Warranties cover 25 years for homes and 10 years for businesses. You can install it over underfloor heating systems. Maximum temperature is 28°C.

Weight runs between 10,672-11,129 g/m². This depends on thickness. The expansion rate stays minimal at 0.03-0.1%. Click-lock systems like Unilin 2G make installation easy. No glue needed on solid subfloors.

Key Features & Performance

SPC flooring gets its strength from an engineered core. Density makes all the difference. Standard SPC cores reach 1,900-2,100 kg/m³. Regular LVT sits at 1,600-1,900 kg/m³. This gap changes how durable your floor is. It also affects how it feels under your feet.

Impact Resistance That Lasts

The rigid core takes a beating. Industry testing (ASTM F970) proves it. Quality SPC products resist 500+ psi without permanent dents. Premium lines go past 1,000 psi. What does this mean for you? Drop furniture. Roll heavy equipment across it. The floor stays flat.

Point load tests show the real strength. Engineers put 250-500 lb static loads on the floor. This mimics heavy furniture weight. The result? Almost no permanent dents. Your dining chairs won’t leave marks. Not even after years of use.

Real Waterproof Protection

Many floors claim to be “waterproof.” SPC proves it with data. Water absorption tests (ASTM D570) show ≤0.5% absorption by weight after 24-72 hours underwater. Most products test at near 0%. This is within standard measurement limits.

Size change shows the truth. After full water soaking, quality SPC floors shift just 0.1-0.25% in length or width. You can install them in wet rooms. Bathrooms, kitchens, basements—manufacturers cover all these. Spills won’t cause swelling or peeling with proper install.

Stable in Any Climate

SPC needs less climate control. Size change stays small at 0.1-0.2% across test ranges from -5°C to 50-60°C. This lets you install continuous floors up to 4,000-10,000 square feet without transition strips. Just leave proper gaps around the edges.

Most warranties specify these ranges: -5°C to 40°C temperature with 30-65% relative humidity. Stay within these limits. This prevents gaps or cupping.

Surface That Protects

Wear layer thickness controls how long your floor lasts. Home SPC uses 6-12 mil (0.15-0.3mm) layers. Light commercial goes to 20 mil (0.5mm). Heavy traffic areas need 28-30 mil (0.7-0.76mm) protection.

Taber tests (ASTM D4060) measure real wear. High-end products last 10,000-20,000 cycles before the pattern wears through. Commercial-grade options exceed 30,000 cycles. Better coatings with ceramic beads resist scratches. They show 30-50% less scratch depth under the same pressure versus standard finishes.

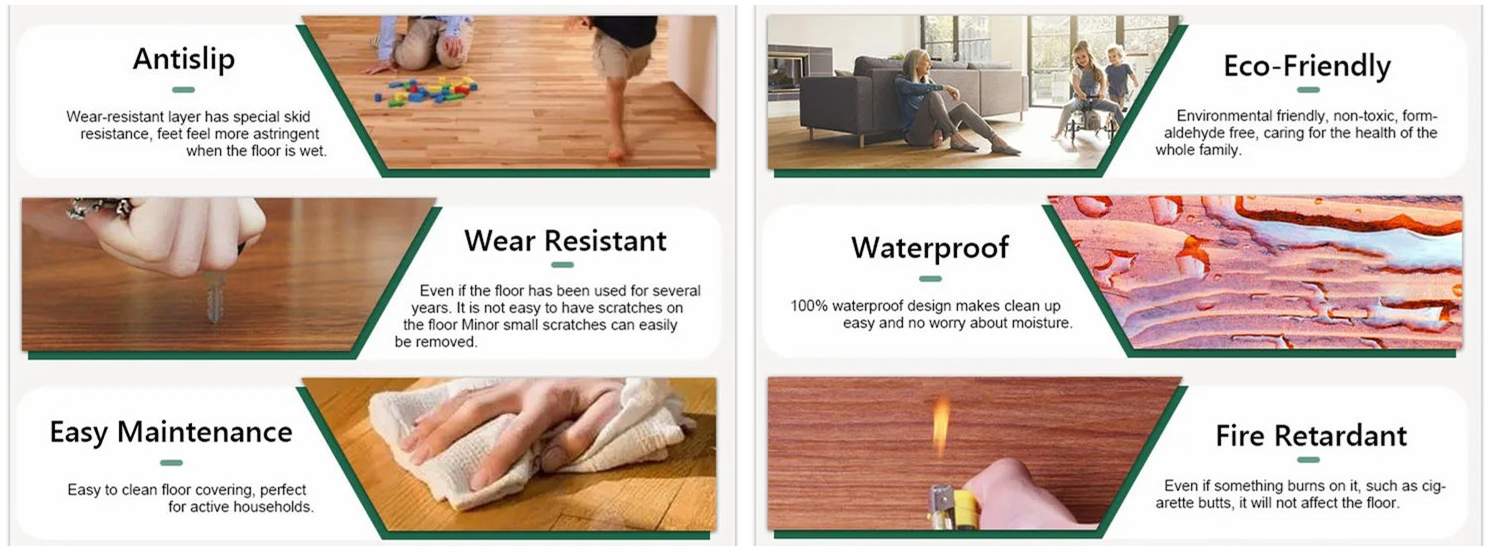

Benefits of SPC Flooring

SPC flooring cuts your costs and saves you headaches. The stone-plastic composite core beats traditional vinyl and laminate in real performance tests.

Built to Handle Real-World Pressure

The rigid core handles up to 2,000 PSI of pressure. No permanent dents. Move refrigerators, drop heavy objects, or roll equipment across it—the floor holds up. Commercial spaces prove this first. Offices with rolling chairs need this strength. Retail stores with display fixtures rely on it. Restaurants with constant foot traffic see the difference.

Your floor stays smooth after years of furniture sitting on it. The construction layers protection: UV coating stops sun damage. The wear layer blocks scratches. The vinyl layer resists stains. These layers keep the surface looking good in homes with active children and pets.

Commercial-Grade Toughness at Home

Contractors install the same flooring in offices, retail stores, and restaurants as they do in homes. The stone-limestone composite makes it stiffer than standard LVT or laminate. This rigid build resists impacts that wreck softer materials.

Temperature swings don’t hurt it. The core stays stable, so you get less expansion and contraction than flexible vinyl. No gaps appear. No buckling happens as seasons change. The floor keeps a tight, clean fit all year.

Water Can’t Touch It

The 100% waterproof rating is real. Over 90% of global SPC products meet or exceed waterproof certification standards in 2023 testing. The stone-plastic core and vinyl layers block all moisture.

Install it in bathrooms. Shower steam won’t damage it. Use it in damp basements. Put it in kitchens where spills happen every day. The floor won’t swell. It won’t warp. Mold doesn’t grow like it does on wood. Humid climates? Spill-prone areas? SPC handles both for years.

Long-Term Value You Can Calculate

Durability saves you money through longer replacement cycles. Many laminates need replacing after 7-10 years. SPC flooring lasts 15-25 years under the same use. This longer life boosts your return on investment by a lot.

Maintenance costs stay low. The scratch-resistant surface needs no refinishing. Water resistance means no replacement costs from leaks or floods. Factor in avoided early replacement from water damage, heavy traffic, or impacts. The total cost over time beats cheaper options.

Quieter Spaces Through Better Design

Over 65% of new SPC products in 2023 included built-in soundproofing. People want acoustic comfort. The pre-attached underpad does two things: it reduces sound transfer between floors and adds cushion underfoot.

Commercial buildings get fewer noise complaints between units. Homes feel quieter with less sound passing through. The rigid core keeps the floor stable. The underlayment soaks up impact noise and footsteps.

Healthier Indoor Environment

Modern SPC products focus on air quality. Many makers offer zero VOC and zero Formaldehyde emissions options. This helps people with sensitivities. It also meets tough commercial building standards.

Fire resistance adds safety. The stone content creates natural fire-retardant properties. Add anti-slip treatments and stain resistance. SPC flooring tackles safety concerns in homes and multi-story commercial buildings.

Proven Market Performance

The flooring industry chose SPC for solid reasons. Digital printing made up 22% of global SPC volume in 2023. This shows strong demand for products that mix durability with custom looks. Contractors pick it because installation works reliably. Property managers choose it because maintenance stays easy. Homeowners buy it because the value makes sense: affordable price with rigid, stable performance that lasts.

Potential Drawbacks / Limitations

SPC flooring delivers serious performance. But the rigid core creates trade-offs. You need to know these before installation.

Firm Surface Feel

The stone-plastic core density runs 1.9–2.1 g/cm³. Traditional flexible LVT sits at 1.3–1.5 g/cm³. This difference hits you underfoot. The floor feels harder. Less cushion. Less give.

Static load tests show SPC handles 500–750 psi before visible dents appear. Flexible LVT shows marks at 250–350 psi. That toughness comes with a trade: 2–5 dB higher impact noise without attached underlay. Footsteps sound louder. The floor feels closer to laminate or engineered wood than soft vinyl.

The 60–70% limestone content makes the surface feel cooler. Bare feet notice it right away. Stand for work? This matters. Studies show resilient LVT with cushion backing cuts leg fatigue for people standing over 4 hours daily. Rigid-core flooring doesn’t give you that relief.

Subfloor Prep Needs

Most makers demand maximum 3mm deviation over 2 meters. Some go tighter: 1.6–3.2mm over 1.8–3 meters. Miss these marks? Problems show up fast.

High spots create rocking planks. Low spots pull click joints apart under weight. Old tile lines, plywood seams, and fastener heads all show through the rigid surface. The thin attached pads—1–1.5mm IXPE or EVA—can’t hide bumps over 1–2mm.

Prep work is critical:

- Map the floor with a 2-meter straightedge

- Grind high spots until they meet tolerance

- Fill low areas with patch compound, smooth it out

- Drive fasteners below surface by 0.5mm minimum; fill the holes

- Fill and stagger plywood seams; never align them with plank joints

Many products limit you to one existing layer. It must bond tight. Embossing over 0.5–1mm needs skim coating. Concrete requires moisture vapor emission ≤5–8 lb/1000 ft²/24h or RH ≤85–95%. Higher numbers? You need vapor barriers.

Extra soft underlay doesn’t work well. Click systems need firm support. Most specs cap underlay at 1–2mm maximum with ≤0.5mm compression under 20kPa load. Go softer, and joints fail.

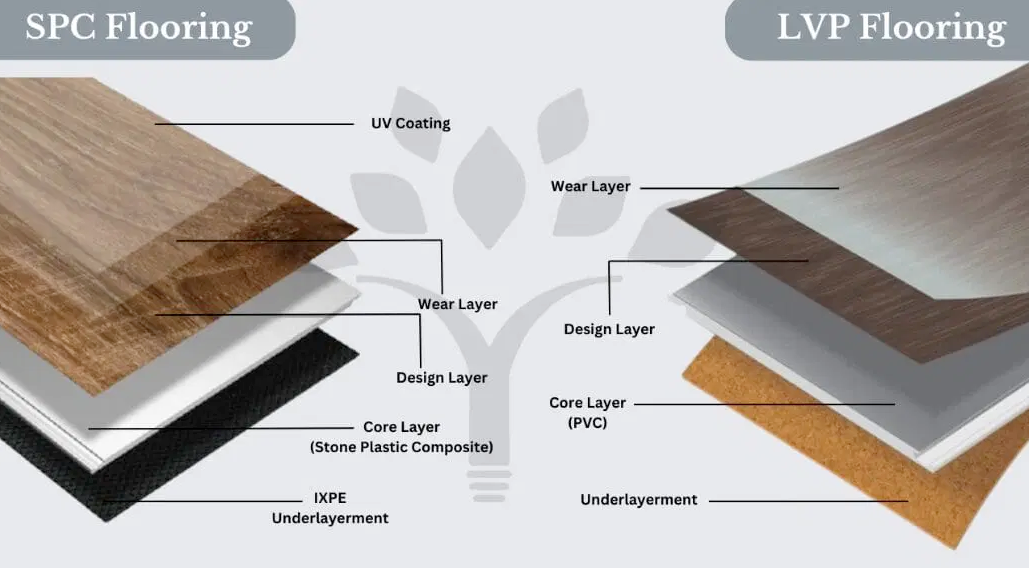

SPC vs. Other Flooring Types (SPC vs. LVT)

Both flooring types look similar. They also need the same maintenance. The real difference? What sits beneath the decorative layer.

Core Construction Changes Everything

Luxury Vinyl Tile (LVT) uses a flexible PVC-based core. Several vinyl layers bond together. This makes it bend and flex under pressure.

SPC flooring takes a different approach. The core contains 70-80% natural limestone powder by weight. Add virgin PVC to this mix. You get a rigid plank that won’t bend.

Density shows the gap. SPC cores run over 5 times denser than standard vinyl. Put a heavy appliance on LVT. Dents form over time. That same weight on SPC? The floor stays flat. No permanent marks appear.

Performance Gaps You’ll Notice

Water creates the clearest split. SPC hits 100% waterproof status through its stone-plastic fusion. Stand water on it for days. No swelling. No warping.

LVT claims water resistance but struggles in wet conditions. High moisture makes edges curl and seams separate.

Temperature and humidity shifts hit LVT harder. The flexible core expands and contracts more than rigid SPC. Gaps open up in winter. Seams push tight in summer. SPC’s rigid limestone core stays stable through these swings.

Wear layer thickness overlaps between both types. You’ll find 6-20 mil options in residential LVT. SPC starts at 12 mil and runs to 20+ mil for heavy traffic. Commercial spaces need 40 mil protection. Both products offer these options.

The difference shows up under pressure. Furniture legs press down. Equipment rolls across. SPC’s rigid base keeps the vinyl layer from compressing. LVT’s soft core lets the wear layer sink a bit under long pressure.

Install and Comfort Trade-Offs

SPC wins on difficult subfloors. The rigid planks bridge minor dips and bumps. Click-lock systems snap together over uneven surfaces.

LVT needs level substrates. You’ll need glue-down methods for stability in most cases.

Barefoot comfort flips the advantage. LVT feels warmer and softer underfoot. That flexible core cushions each step. SPC’s dense limestone makes the surface feel harder and colder. Stand for long periods? Your feet and legs feel the difference.

Pick SPC for basements, commercial kitchens, and high-traffic entries. Moisture and impacts hit these spaces hard. Choose LVT for bedrooms, living rooms, and similar spaces. Comfort beats extreme durability in these areas.

Installation of SPC Flooring

Click-lock systems run most SPC flooring installation projects. Over 85% of homes use floating methods. No glue. No nails. Planks snap together through interlocking parts. You can walk on the floor right after you finish.

Two Primary Installation Methods

Floating click-lock works on any grade level. The floor sits loose over the subfloor. Angle each plank into the next one at 20-30 degrees. Push the long edge together. Rotate down until it clicks. A tapping block and rubber mallet lock planks tight without damaging edges.

Glue-down installation bonds planks straight to wood or concrete. Spread approved adhesive across the surface. Set planks into wet glue. Roll the entire floor right away with a 100-pound three-section roller. This method works just on-grade or above-grade. Below-grade spaces need floating installation. Moisture is the concern.

Site Preparation That Prevents Problems

Control temperature and humidity minimum 5 days before installation. Keep the space at 60-80°F with 30-60% relative humidity. Hold these conditions during and after installation. Floor temperature over radiant systems can’t go above 85°F (30°C).

New concrete or gypcrete needs 4 weeks minimum curing time. Run radiant heat systems at two-thirds max output for 2-3 days before installation. Shut the system off 24 hours before laying planks. Temperature sensors help you track heat levels.

Test concrete moisture to prevent future failures. Use ASTM F2170 in-situ relative humidity tests or calcium chloride methods. Results tell you if you need vapor barriers. Roll out 6-mil polyethylene sheeting over concrete subfloors. Overlap seams by 6 inches. Install this row-by-row as you lay planks.

Subfloor Standards You Must Meet

Maximum slope tolerance is 1 inch per 6 feet (2.5 cm per 1.8 meters). Gaps can’t exceed 3/16 inch (5 mm). Check the entire surface with a straightedge.

Fill all low spots and cracks with leveling compound rated for minimum 3000 psi compressive strength. Grind down high spots. Drive protruding fasteners below the surface. Patch the holes smooth.

Existing hard surfaces work as substrates with the right prep. One layer of stuck-down linoleum is fine. Non-cushioned vinyl, terrazzo, ceramic tile, and stone tile all work. Patch grout lines flush with surrounding tile. Never install over carpet, foam backing, or cushion-backed vinyl.

Extra underlayment over existing floors needs tight control. Maximum thickness is 0.06 inches (1.5 mm) with minimum 30-pound density. Cork, rubber, and soft foam create problems. They compress too much under weight. Click joints separate as the base shifts.

Layout Planning Prevents Narrow Strips

Divide room width by plank width before cutting anything. Is the final row less than 2.5 inches (64 mm)? Adjust your starting row width. This keeps both the first and last rows at good sizes.

Don’t align plank joints over subfloor seams. Stagger end joints by one-third to one-half plank length. This creates a brick pattern. It also spreads weight better across the floor system.

Undercut door jambs and casings. Planks slide underneath for clean transitions. This beats trying to scribe cuts around odd shapes.

Step-by-Step Floating Installation

-

Acclimate and inspect: Open multiple cartons. Mix planks from different boxes. Check for defects before installation.

-

Prepare the workspace: Clean and sweep the subfloor well. Remove all debris.

-

Install vapor barrier: Lay 6-mil poly over concrete with overlapping seams.

-

Start the first row: Place 1/4-inch spacers along the wall. Position the first plank with the groove side facing the wall. This creates proper expansion space.

-

Connect planks: Angle the next plank 20-30 degrees. Push the long edge into the groove. Rotate down until you hear the click. Tap lightly with a tapping block if needed.

-

Build next rows: Cut the end plank from the previous row to start the next row. This keeps the proper stagger. Offset joints by at least one-third plank length.

-

Finish the last row: Rip planks to width as needed. Use a pull bar to close gaps where a tapping block won’t fit.

Expansion Space Requirements

Leave 1/4 inch (6.35 mm) around the entire edge. Large installations over 2,500 square feet (50′ x 50′) need 1/2 inch (12.7 mm) expansion gaps. Some specs call for 10 mm spacing no matter the size.

Maximum area limits are 6,400 square feet (620 m²) or 80 linear feet (25 meters) in any direction. Bigger spaces need T-moldings to create separate floating sections.

Final Steps for Lasting Results

Install base moldings and transition strips to walls—never to the floor itself. Keep at least 1/4 inch clearance beneath moldings. This lets the floor expand and contract.

Caulk wet areas with 100% silicone. Bathrooms need sealed edges where water hits. This stops moisture from reaching subfloors through edge gaps.

Protect new floors from direct sunlight during the first 48 hours. UV exposure can affect adhesive curing in some wear layer coatings.

Essential Tool List

- Tape measure and T-square for accurate cuts

- Utility knife and jigsaw for trimming planks

- Tapping block and rubber mallet for tight connections

- Pull bar for the last row and tight spaces

- 1/4-inch spacers to maintain expansion gaps

- Broom and vacuum for subfloor cleaning

Special Considerations for Crawl Spaces

Below-grade installations over crawl spaces need minimum 18-inch clearance from ground to floor joists. Ventilation must equal 1.5% of the crawl space square footage. These requirements stop moisture buildup that damages flooring systems over time.

Conclusion

SPC flooring has earned its spot as a top flooring choice. You get a waterproof core that stands up to spills. Plus, it’s tough and easy to install yourself. Homeowners love it. Landlords trust it. Commercial spaces rely on it.

Renovating a bathroom that gets wet? SPC handles moisture. Need flooring for busy hallways? It takes the traffic. Want that real wood look minus the upkeep? This delivers.

SPC flooring adapts to how you live. It doesn’t fight your routine. Yes, temperature can affect installation. But for most uses, the pros beat the cons by a mile.

Ready to transform your space? Measure your room first. Browse styles that match your vision. Check the manufacturer’s install guide. Still deciding? Grab some samples. Touch them. See the quality up close. Your perfect floor is within reach. SPC gives you a floor built for decades, not just a few years.