Stone-Look LVP vs Porcelain Tile: A Complete Buying Guide for Homeowners

You’re in the flooring aisle, choosing between stone-look luxury vinyl plank and porcelain tile. Both look like natural stone, but which one works for your lifestyle and budget?

Choosing between stone-look LVP vs porcelain tile goes beyond appearance. Weight differences decide where you can install each type. Heat affects how they work with radiant floors or sunny rooms. Durability, installation, and long-term costs? These factors might change your mind.

We’re comparing seven key points. You’ll see how well each mimics real stone. You’ll learn what it’s like living with them every day. By the end, you’ll know which flooring fits your home (and which one’s just good marketing).

Stone-Look LVP vs Porcelain Tile: Realistic Stone Appearance Comparison

Modern printing tech has made it tough to tell fake from real. Stone-look LVP uses sharp photos and embossing to copy natural stone patterns. Each plank shows veining, color shifts, and surface texture you’d find in real stone. You’ll see slate grays, travertine beiges, and marble whites that look genuine. The embossed wear layer adds texture that matches the pattern underneath.

Porcelain tile works differently. Digital printers put multiple color and pattern layers onto the tile body during production. Premium porcelain creates realistic stone looks with random patterns across tiles. No two pieces look the same. The glaze adds depth that copies how natural stone plays with light. High-end porcelain tiles can trick even skilled contractors from afar.

Visual Realism Up Close

Stand three feet away. Both materials look like natural stone to most people. Move closer. Differences show up.

LVP shows a pattern that repeats every 10-30 planks. This depends on the product line. Budget lines might repeat every 6-8 planks. Large rooms show these pattern cycles clearly. The embossing depth stays under 0.5mm. This limits how real it feels underfoot. Some LVP products have glossy finishes. These create a fake sheen that natural stone never has.

Porcelain tile gives you better pattern variety. Premium lines provide 50+ unique face designs. You won’t see obvious repeats in home installations. The surface texture goes deep. Some tiles feature 2-3mm relief that copies natural stone clefts and ridges. Matte finishes look more real than polished versions. Polished can look too perfect.

The Light Test

Light shows each material’s true nature. LVP reflects light evenly across its surface. The protective wear layer causes this. Porcelain’s glazed surface works with light like natural stone does. Each tile catches light differently throughout the day. This creates subtle shifts.

Heat Conductivity: LVP vs Porcelain on Radiant Floors

Radiant floor heating changes how these materials work. Stone-look LVP and porcelain tile react in different ways to temperature changes. This affects your comfort, energy bills, and installation options.

Porcelain tile moves heat well. The dense ceramic pulls warmth from heat sources. It spreads that warmth across the surface. Thermal conductivity sits at 1.0–1.5 W/(m·K). Connect porcelain to radiant heating. The floor warms up in 20–30 minutes. The tile holds that heat. It releases warmth even after the system turns off. Cold mornings? Porcelain floors stay warm underfoot for hours. This works both ways. Porcelain keeps rooms cooler in summer by soaking up extra heat during the day.

Stone-look LVP blocks heat instead of moving it. Vinyl’s thermal conductivity is much lower at 0.15–0.25 W/(m·K). That’s 5–10 times less than porcelain. Install LVP over radiant heat. You’ll wait 45–60 minutes for warmth you can feel. The vinyl layer blocks heat between the source and your feet. Most makers limit radiant system temps to 80–85°F (27–29°C) for LVP. Go hotter? You risk warping, separation, or gas release from adhesives. Check your product specs. Some budget LVP brands don’t allow radiant heat at all.

Temperature Stability

Porcelain handles extreme temps without damage. Freeze-thaw cycles? No problem. Porcelain stays solid from −40°F to 200°F (−40°C to 93°C). Sunny rooms with floor temps hitting 120°F won’t hurt it. The material doesn’t expand or shrink much with normal indoor temp changes.

LVP moves with heat. Vinyl grows 0.02–0.04 inches per 10°F rise over a 12-foot run. Installers leave gaps (¼–½ inch) at walls for this. Direct sun through big windows can push surface temps past 100°F. You’ll see gaps open between planks. Or buckling in bad cases. Climate-controlled homes cut these problems. But three-season porches or rooms with lots of solar gain? That’s risky for LVP.

Energy Efficiency Impact

Porcelain’s heat storage cuts heating costs in radiant setups. The floor stores heat during on-cycles. It releases heat during off-cycles. Systems run less often but keep you comfortable. LVP’s blocking traits fight against radiant systems. More energy heats the vinyl barrier before reaching your living space. For underfloor heating projects, porcelain gives 15–25% better energy transfer based on real installs. That gap adds up over a 20-year floor life.

Scratch & Wear Resistance: Stone-Look LVP vs Porcelain Tile

Floors take abuse every day. Dropped pans, dragged furniture, pet claws, grit from outside—all test your flooring. Stone-look LVP vs porcelain tile handle wear in different ways. One flexes and absorbs impact. The other stands rigid and resists scratches.

Stone-look LVP fights scratches with its wear layer thickness. Entry-level products use 6–8 mil wear layers. These work for light home use. But they show scratches more. Standard home LVP jumps to 12–20 mil. This handles typical homes well. Light commercial options run 20–28 mil. You get higher scratch resistance. Heavy-traffic commercial products? You’ll see 28–40+ mil wear layers. These resist serious abrasion. Testing backs this up. Home LVP hits 5,000–10,000 cycles in Taber abrasion tests before visible wear. Commercial versions? They push 20,000–40,000+ cycles to wear-through.

Pet claws and chair casters won’t damage 20 mil+ products. But here’s the catch—sharp objects can cut the vinyl. Drop a knife or heavy tool? You might puncture through to the softer core underneath. The material can’t match ceramic’s hardness.

Porcelain tile ranks 7–8 on the Mohs hardness scale. That’s quartz-level hardness. The PEI rating system grades glazed surfaces. Class 3 handles light to medium home traffic. Class 4 works for heavy home or light commercial spaces. Class 5 takes on heavy commercial areas with very high traffic. Sand, dirt, chair legs, pet claws—none of these scratch porcelain’s surface. You’d need diamond tools to make significant marks on the tile body.

Impact Resistance

Drop something heavy on LVP. The flexible core absorbs the impact. ASTM F970 testing shows quality LVP products dent ≤0.005–0.010 inches under 250 psi after 24 hours. Enhanced commercial products limit denting to ≤0.005 inches even at 1,000 psi. Drop tests using 1–1.8 inch steel balls from 36–60 inches? LVP passes without cracking. You might see minor surface marking. But no structural failure.

This flexibility works both ways. LVP handles subfloor deflection and movement without cracking. But heavy point loads can cause permanent dents. Think refrigerators on narrow wheels without protective pads. Static pressure above the product’s psi rating will leave marks over time.

Porcelain shows the opposite behavior. Floor-rated tiles have breaking strength of 250–400 lbf minimum. Modulus of rupture tests (ASTM C648) show common floor porcelain at ≥2,500–4,000 psi. The tile won’t dent under weight. Instead, it’s brittle. Drop a cast-iron pan? You risk chips or cracks. Subfloor voids, deflection, or movement can cause tiles to crack. Heavy point loads near unsupported areas create fracture risks. The failure mode is breaking, not denting.

Long-Term Performance

Water and stains test both materials daily. Many SPC/WPC stone-look LVP products claim 100% waterproof cores. Surface water won’t cause swelling. But seams can let moisture reach your subfloor. Tight installation prevents this. Stain testing (iodine, coffee, ketchup, shoe polish) shows no visible changes after proper cleaning. The wear layer protects well. Temperature changes cause small movements. SPC cores expand ≤0.02–0.03% over normal ranges. Floating installations need ¼–½ inch expansion gaps to prevent buckling.

Porcelain tile absorbs ≤0.5% water by weight (ASTM C373). This makes it suitable for wet areas, pools, and exterior installations with proper rating. Freeze-thaw cycles don’t hurt it. Unglazed through-body porcelain resists stain penetration. You can clean it with mechanical methods. Glazed surfaces pass PEI stain-resistance tests with no visible change after common household chemical exposure. Temperature shifts affect porcelain very little. The fired ceramic body stays stable through extreme conditions.

Cost

You’ll feel the price difference before installation day arrives. Stone-look LVP material runs $1.00–$7.00+ per square foot depending on quality. Budget lines start around $1.00–$2.50 per square foot. Most homeowners pick mid-range options at $2.50–$4.00 per square foot. Premium LVP with better wear layers and realistic embossing costs $4.00–$7.00+ per square foot. A 200-square-foot room needs about $500–$800 in materials at mid-range pricing.

Porcelain tile starts higher and climbs faster. Budget porcelain begins at $2.00–$4.00 per square foot. Mid-range stone-look tiles run $4.00–$7.00 per square foot. Designer lines with large formats or unique patterns? You’ll pay $7.00–$15.00+ per square foot. That same 200-square-foot space needs $800–$1,400 in tile alone before you buy a single bag of thinset.

Installation Costs Change Everything

LVP installation keeps costs down. Click-lock systems work great for DIY projects. You just need basic tools. Add $0.50–$1.50 per square foot for underlayment, trim, and supplies. Your labor cost? Zero if you install it yourself. Hire a pro for floating LVP and expect $1.50–$3.50 per square foot labor. Glue-down or complex patterns bump that to $4.00–$5.00 per square foot in high-cost areas. Total installed cost for mid-range LVP usually hits $4.50–$7.00 per square foot.

Porcelain needs professional skills and patience. Setting materials alone—backer board, thinset, grout, spacers—add $1.00–$3.00 per square foot. Labor runs $5.00–$10.00 per square foot for standard layouts. Large-format tiles, herringbone patterns, or tight grout lines? Labor jumps to $8.00–$15.00+ per square foot. Mid-range porcelain installations usually total $10.00–$15.00 per square foot all-in.

Check the numbers for that 200-square-foot room with mid-range products and professional installation. LVP costs about $1,300 total (~$6.50 per square foot). Porcelain hits $2,000–$3,000 (~$10–$15 per square foot). Porcelain’s installed cost runs 2–3× higher than LVP for similar looks.

Installation: LVP vs Porcelain Tile

Stone-look LVP turns into a weekend DIY project with basic hand tools. Most products have click-lock edges that snap together without glue or nails. You’ll lay underlayment, cut planks with a utility knife or vinyl cutter, and click rows together. The floating install puts planks on top of your subfloor—they don’t attach. Working around doorways and fixtures takes patience. But you don’t need special skills. A 200-square-foot room? First-timers need 6–10 hours. People with experience finish in 4–6 hours.

Glue-down LVP takes more work. You’ll spread glue with a notched trowel, set planks, and roll them for full contact. This method suits commercial spaces better. Also good for areas with heavy point loads. The install takes twice as long. You need fresh air for glue fumes. But the floor stays put—no gaps from seasonal movement.

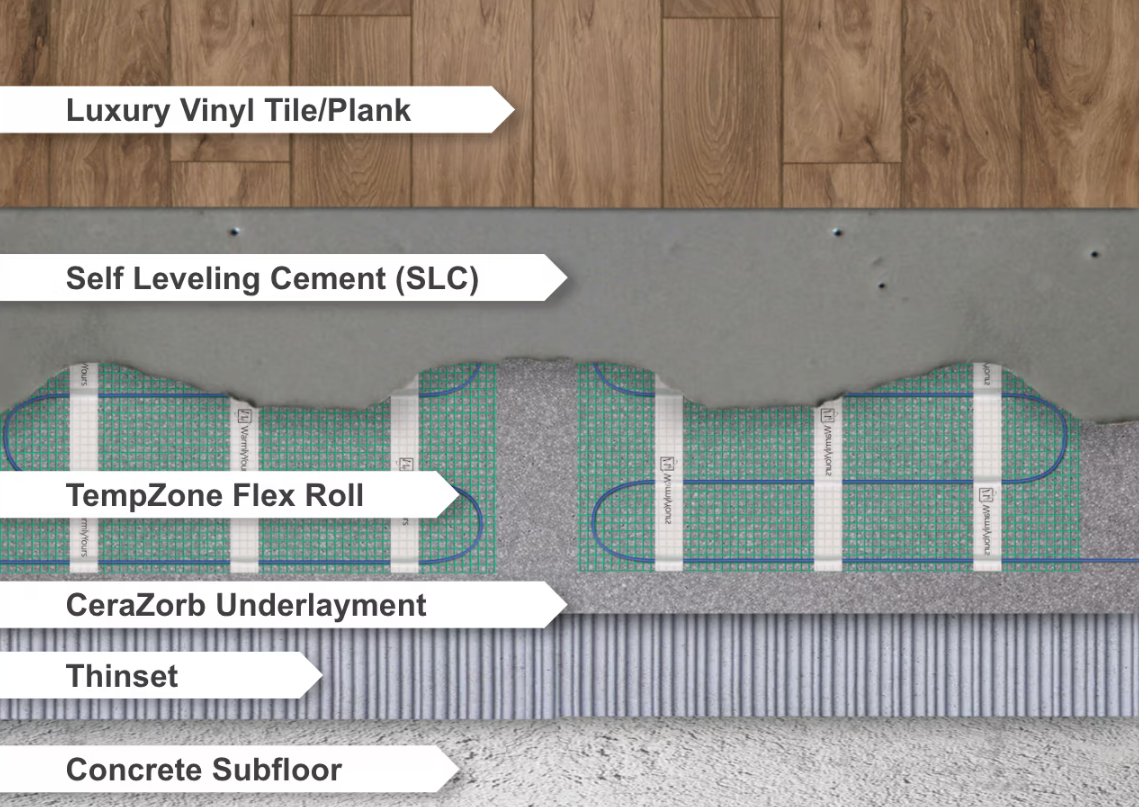

Porcelain tile needs precision and pro tools from the start. The subfloor must be flat. Bumps over 1/8 inch in 10 feet cause uneven edges or cracked tiles. You’ll often put down cement backer board first. Mix thinset mortar to the right thickness. Spread it with the correct notched trowel. Trowel size changes based on tile size. Set each tile with a slight twist for full contact. Spacers keep grout lines even. Large tiles (24″ × 48″) need special clips and wedges. These keep tiles level while they cure.

Cuts need a wet saw with diamond blade. Notches around pipes or outlets? Use a tile nipper or angle grinder. After 24–48 hours of thinset cure time, you mix and add grout. Then seal it. That same 200-square-foot room takes pros 12–20 hours. The work spreads across 3–4 days because of cure times.

Subfloor Requirements

LVP handles small subfloor flaws. Bumps up to 3/16 inch over 10 feet work fine with good underlayment. You can install over vinyl, tile, or concrete. Just make sure the surface is clean and dry.

Porcelain needs nearly perfect prep. Use self-leveling compound to fix low spots. Grind down high spots. Wooden subfloors can’t flex more than L/360 (the industry standard). Too much flex? Tiles crack at grout lines. Concrete slabs need moisture testing. Readings over 3 lbs/1000 ft² mean you need vapor barriers before tile install.

Conclusion

Stone-look LVP vs porcelain tile – your choice depends on lifestyle and project needs. LVP works great if you want authentic stone looks with a warmer feel underfoot. Plus, it’s easier on your budget and simple to install. You get impressive stone aesthetics without the heavy weight or cold surface. Porcelain tile shines in extreme heat. It lasts a lifetime and delivers that premium feel buyers love.

Neither option wins across the board. They just fit different needs. LVP works best for DIY projects, upper floors, and rooms where comfort comes first. Porcelain takes the lead in high-heat areas, heavy traffic zones, and luxury spaces where only real quality will do.

Ready to decide? Download our free comparison checklist. It covers room-by-room factors to help you choose. Or talk to a flooring specialist who can check your subfloor and traffic patterns. Your perfect floor matches material strengths to what your home actually needs – not just what’s trending.