Picking the right flooring goes beyond looks. It’s a key safety choice that can prevent slip-and-fall accidents in your home or business.

Spc Flooring slip resistance ratings—R9, R10, and R11—tell you if a surface is safe for your space. These simple numbers show angle measurements. They help you know where to install your flooring, from dry living rooms to wet commercial kitchens.

Are you a homeowner fixing up your bathroom? Maybe you’re a contractor choosing materials for a restaurant. Or perhaps you manage a facility and need to meet safety rules. These ratings help you make smart choices. They protect people and your money.

This guide explains the testing methods and real-world uses. You’ll see why Spc Flooring slip resistance ratings matter for safer spaces. Plus, we cover the key factors you need to know before buying.

Slip Resistance Standards Overview

Testing standards measure SPC flooring slip resistance through scientific methods. These methods simulate real-world conditions. Different regions use distinct systems. They all measure the same thing: how much grip your floor provides.

European R-Rating System (DIN 51130)

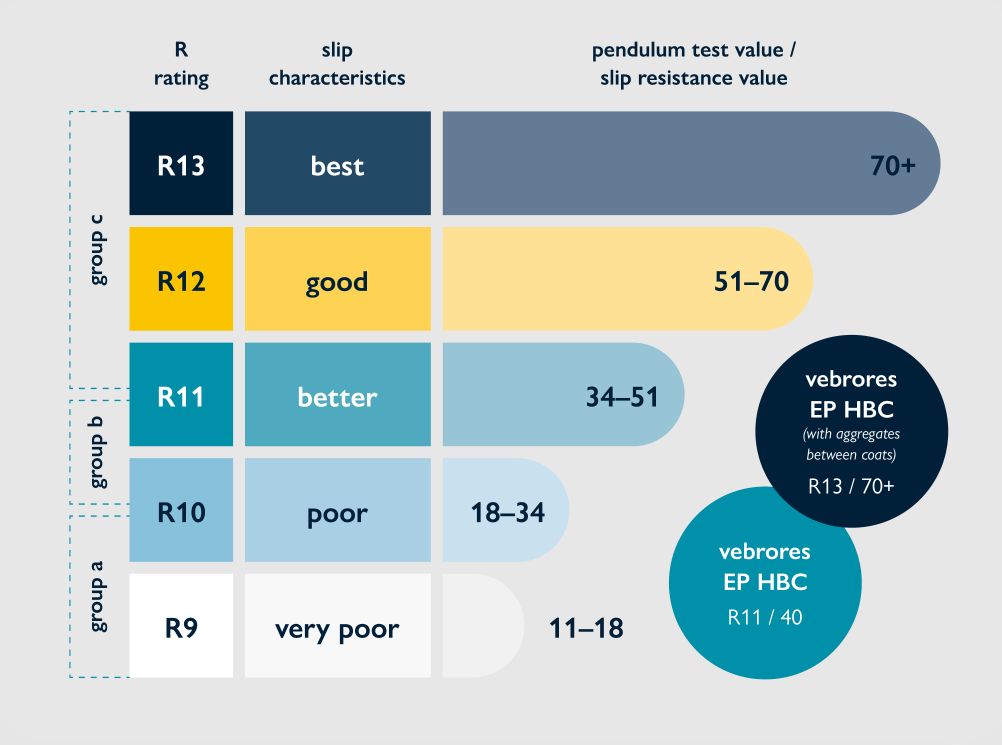

The R-rating system tests flooring using an inclined ramp covered with oil. A person wearing standard footwear walks on the ramp. Technicians increase the angle. The angle at which slipping occurs determines the rating:

- R9: 6-10° angle—suitable for dry indoor offices and residential rooms

- R10: 10-19° angle—the standard for most commercial LVT and SPC flooring, handling moderate traffic

- R11: 19-27° angle—designed for areas with occasional wet conditions

- R12: 27-35° angle—heavy-duty applications with frequent moisture

- R13: Above 35° angle—industrial zones with oil, grease, or steep ramps

Pool decks and showers need different testing. Europe applies DIN 51097 for barefoot traffic in wet areas. This test uses water instead of oil. The system uses A, B, and C ratings. C offers the highest barefoot slip resistance.

North American DCOF Standard (ASTM E303)

The United States and Canada use the Dynamic Coefficient of Friction (DCOF) measurement. Testing equipment drags a standard rubber sensor across wet flooring at controlled speed. This measures resistance force.

ANSI A326.3 requires a minimum DCOF of 0.42 for wet interior hard surfaces in commercial settings. Ramps need much higher performance—0.8 or above. ADA accessibility guidelines set this requirement. These numbers are friction coefficients. Higher values mean better grip.

Australian P-Rating System (AS 4586:2013)

Australia uses a pendulum testing device. This device swings across wet flooring surfaces. The pendulum’s friction loss generates P-ratings from P1 (lowest) to P5 (highest). Wet commercial areas and ramps require P3 or higher ratings to meet building codes.

Understanding Test Equipment

Over 50 countries recognize pendulum testers as reliable measurement tools. Standards like BS EN 16165:2021, BS EN 13036-4:2011, AS 4663:2013, and ASTM E303-22 govern testing procedures. These devices measure dynamic friction. This is the resistance your foot encounters during active walking motion, not just static standing.

Testing differences affect accuracy. BS EN 13287 measures friction between 0.3 and 0.6 seconds after initial sliding begins. SATRA TM144 captures data at 0.1 seconds (±0.01s). SATRA specifies a 40mm sliding distance. BS EN standards leave this undefined.

R Rating Scale and Angle Ranges

The R-rating system turns physics into safety numbers you can use. Each rating links to a specific angle range from the DIN 51130 ramp test. These ranges help you pick the right SPC flooring slip resistance for your space.

Breaking Down the Five R-Rating Categories

The test ramp starts flat. Then it tilts up slowly. Technicians watch for the exact angle where someone in cleated boots starts to slip on the oiled surface. That angle sets the rating:

R9 (3°-10° angle) means minimal friction. This works for dry spaces with almost no moisture. Think building lobbies, indoor showrooms, and bedrooms. R9 flooring is all these spaces need. The low angle tells you grip is limited once things get wet.

R10 (10°-19° angle) gives you normal friction for daily commercial use. Most SPC flooring products aim for this middle rating. R10 fits office hallways, retail stores, and covered outdoor entries. These spots see little water but need more grip than bone-dry rooms.

R11 (19°-27° angle) delivers high friction for wet areas. Home bathrooms, rain-exposed outdoor paths, and commercial restrooms all benefit here. The steeper angle shows the floor keeps its grip even with regular moisture. Many porcelain tiles and quality vinyl planks hit R11 standards.

R12 (27°-35° angle) tackles heavy contamination. Industrial workshops, car garages, and roadside zones with oil or grease need this friction level. The steep angle shows strong slip resistance in tough conditions.

R13 (above 35° angle) gives maximum slip resistance for extreme settings. Industrial sites with constant oil or steep loading ramps need this top rating. Few homes or standard commercial spaces require R13.

Comparing with Other Friction Tests

The British Pendulum Test (BS7976) uses different benchmarks. PTV values below 25 mean high slip risk. Values of 25-35 show moderate risk. The 35-65 range signals low risk. Readings above 65 confirm very low slip danger. R-ratings measure angles. PTV measures pendulum friction loss. Two different ways to answer the same safety question.

Spanish standard UNE ENV 12.633 uses slope classes. Class 0 is less than 15° PTV on dry surfaces. Class 1 covers 15° to less than 35° slopes. Class 2 handles 35° to less than 45° wet inclines. Class 3 manages slopes over 45°. These systems let contractors check that SPC flooring slip resistance meets local codes, no matter which test the region prefers.

Applications by R Rating

Choose the right SPC flooring slip resistance rating for your space. This ensures safety and meets code requirements. Each R-rating fits different areas based on how much moisture and contamination you expect.

R9 Applications: Dry Indoor Environments

R9 flooring works in spaces that stay dry all year. The 3-10° angle rating gives enough grip where water never touches the surface.

Residential spaces like living rooms, bedrooms, and home offices pair well with R9. People walk through these rooms in socks or soft-soled shoes. Spills happen rarely and get wiped up fast.

Commercial hallways in office buildings stay dry thanks to HVAC systems and regular cleaning. R9 SPC flooring provides the basic slip resistance these corridors need. No need to go higher.

Retail showrooms that display furniture, electronics, or clothing work great with R9 ratings. Indoor climate control keeps floors dry. The smooth surface makes it easy to roll displays and carts around.

R10 Applications: Light Moisture Zones

R10 fits spaces where things get wet sometimes but don’t stay that way. The 10-19° angle range offers moderate grip for short-term wetness.

Home kitchens get spills from cooking and dishwashing now and then. R10 flooring handles these quick wet moments. Cleanup stays simple. Put absorbent mats near sinks for extra protection.

Utility rooms with washers and dryers see moisture from laundry from time to time. R10 gives enough traction during these brief wet spells.

Bathroom applications work with R10 if you use bath mats in smart spots. Put mats at tub and shower exits. The flooring takes care of minor splashes from hand-washing.

Changing rooms in gyms or retail stores deal with damp feet and the odd puddle. R10 gives athletes and shoppers stable footing as they move through fast.

Covered entryways get tracked-in moisture even though they’re protected from direct rain. R10 levels handle wet shoes without turning into a hazard.

R11 Applications: Frequent Wet Conditions

R11 works in areas where water shows up every day. The 19-27° angle threshold keeps things safe even on surfaces that stay wet for hours.

Full bathrooms without mat systems need R11 ratings. Shower steam, splashing water, and cleaning create constant moisture. R11 SPC flooring slip resistance keeps you safe during morning showers and evening baths.

Wet rooms with curbless showers need R11 at minimum. These designs let water spread across bigger floor areas. The extra grip stops falls on soaked surfaces.

Commercial kitchens in restaurants deal with cooking oil, spilled drinks, and constant mopping. R11 flooring gives kitchen staff secure footing during rush hours. Floors get messy fast in these spaces.

Home laundry rooms with several machines or basement setups benefit from R11. Washing machine overflows and dryer condensation create slip risks. R11 handles these issues.

Outdoor patios under partial cover get hit with rain and morning dew. R11 manages these natural moisture cycles. It also supports furniture and foot traffic.

R12 Applications: Heavy Contamination Areas

R12 fits areas where water mixes with oils or other slippery stuff. The 27-35° angle capability handles tough contamination.

Pool surrounds mix standing water with body oils and sunscreen residue. R12 gives swimmers and pool staff solid traction on wet decking that never dries.

Industrial kitchens in hotels, hospitals, and big food operations face grease, oil spills, and constant water use. R12 protects workers as they carry hot equipment across slick floors.

R13 Applications: Extreme Slip Hazards

R13 provides maximum resistance for the toughest spots. The above-35° angle rating handles severe conditions that go beyond typical SPC flooring uses.

Shower floors in commercial buildings need R13 where bare feet mix with soap and shampoo. Health clubs, hotels, and senior living centers make this top-tier safety a priority.

Public pool areas with diving boards and splash zones require R13. Constant water, chemical treatments, and heavy use call for the highest slip protection.

Food processing plants that work with animal fats, vegetable oils, and industrial cleaning agents need R13. Production line safety depends on this extreme grip level.

Testing Methods

Labs test SPC flooring slip resistance through physical tests. These tests copy real walking conditions. Two main methods set global standards: the ramp test and the pendulum test. Both use different tools. Both measure the same thing—how much grip a floor gives you.

The Ramp Test Method (DIN 51130)

The European ramp test works like this: A person wears standard safety shoes. They walk on a tilting platform. Technicians spread motor oil on the test surface. This mimics contamination. The platform starts flat. Then it tilts up bit by bit. Observers watch for the exact angle where the person’s foot starts to slip.

Safety shoes must meet SRA class requirements with a coefficient of friction (COF) between 0.17 and 0.28. This standard footwear keeps results the same across different test labs. The slip angle converts to R-ratings:

- R9: Less than 10° angle = under 0.2 COF on dry surfaces

- R10: 10-19° range = 0.2-0.4 COF for general indoor spaces

- R11: 19-27° = 0.4-0.5 COF on wet ramps and bathroom floors

- R12: 27-35° = over 0.5 COF for outdoor slopes with frequent moisture

- R13: Above 35° = 0.7+ COF for extreme wet or oil-covered industrial zones

The oil coating makes this test tougher than normal dry walking. Results show you how flooring holds up in worst-case dirty conditions.

The Pendulum Test Method (BS 7976/TS 15574)

British and global standards use pendulum testing devices. A weighted arm swings across the floor. A rubber slider drags against the material. Sensors track how much the slider resists movement. This creates a Pendulum Test Value (PTV).

PTV scores match R-ratings: PTV 36 or higher = R10. PTV between 25 and 35 = R9. Readings below PTV 25 mean high slip risk. These fail basic safety standards.

Four slider types handle different test conditions:

- TRRL slider: Tests dry surfaces with hard rubber compound

- Wet slider: Measures standard water-covered floors

- Four S slider: Copies soft shoe soles on wet surfaces

- Oil-wet slider: Tests performance with oil contamination

Test labs pick slider types based on where you’ll use the flooring. Wet sliders fit bathroom SPC flooring slip resistance checks. Oil-wet sliders fit commercial kitchen materials.

SPC Flooring Slip Resistance — Professional Selection Reference Table

The right SPC flooring slip resistance rating does more than meet safety codes. It protects everyone who walks on your floors daily. You might install R9-rated flooring in your bedroom. Or you need R11-rated surfaces in a commercial kitchen. These standards help you balance looks, function, and safety.

| Area / Application Scenario | Moisture Level | Footwear Type | Recommended Slip Rating | Standard Reference | Notes |

|---|---|---|---|---|---|

| Bedrooms, Living Rooms | Dry | Socks / Soft shoes | R9 | DIN 51130 | Residential dry zones; no standing water |

| Offices & Corporate Corridors | Dry | Leather / Rubber sole | R9 – R10 | DIN 51130 | R10 preferred for higher traffic |

| Retail Stores & Showrooms | Occasionally wet | Rubber sole | R10 | DIN 51130 | Handles cleaning moisture & tracked-in water |

| Home Kitchens | Occasionally wet | Rubber sole | R10 | DIN 51130 | Use anti-slip mats near sink areas |

| Utility / Laundry Rooms | Light moisture | Rubber sole | R10 | DIN 51130 | Short-term water exposure |

| Residential Bathrooms | Frequent wet | Barefoot / Rubber sole | R11 | DIN 51130 / DIN 51097 | R11 minimum recommended |

| Barrier-Free Bathrooms / Wet Rooms | Constant wet | Barefoot | R11 (Class C barefoot) | DIN 51097 | Critical for fall prevention |

| Commercial Restrooms | Frequent wet | Work shoes | R11 | DIN 51130 | Mandatory for public safety |

| Restaurant Kitchens | Oil + water | Anti-slip shoes | R11 – R12 | DIN 51130 | Grease contamination present |

| Hotel / Hospital Kitchens | Heavy contamination | Safety footwear | R12 | DIN 51130 | High-liability environment |

| Pool Surrounds & Decks | Standing water | Barefoot | R12 – R13 | DIN 51097 | Constant moisture + sunscreen oils |

| Industrial Food Processing | Oil / Fat | Safety boots | R13 | DIN 51130 | Extreme slip-risk conditions |

| ADA Ramps (North America) | Wet | Mixed footwear | DCOF ≥ 0.42 | ANSI A326.3 | Higher values needed for slopes |

| Commercial Ramps & Slopes | Wet | Mixed footwear | DCOF ≥ 0.80 | ADA Guidelines | Required for accessibility compliance |