Recycled vs. Virgin Vinyl LVP: A B2B Perspective on Performance, Sustainability, and Lifecycle Impact

When evaluating recycled vs. virgin vinyl LVP, the decision extends well beyond surface aesthetics or short-term cost. Material selection directly affects manufacturing consistency, regulatory compliance, environmental reporting, and long-term product performance across large-scale projects.

The vinyl flooring industry has shifted rapidly toward recycled content in response to sustainability targets and global regulations. Recycled vinyl LVP offers potential advantages in carbon footprint reduction and waste diversion, while virgin vinyl continues to set the standard for formulation stability, dimensional consistency, and quality control. The key question for B2B buyers is whether recycled-content LVP can deliver the same reliability, durability, and risk control required for commercial and export applications.

This analysis compares recycled and virgin vinyl LVP from a professional perspective—examining raw material sourcing, production impact, performance consistency, compliance considerations, and lifecycle value. The goal is to support informed decisions for manufacturers, distributors, contractors, and project owners balancing sustainability objectives with long-term operational requirements.

Evaluating Recycled vs Virgin Vinyl LVP: What You Need to Know

Evaluating Recycled vs Virgin Vinyl LVP: What You Need to Know

When selecting vinyl LVP for your projects, whether for commercial buildings, offices, or high-traffic residential spaces, it’s crucial to look beyond marketing claims. Durability, water resistance, and environmental impact are often highlighted—but not every product delivers equally. Understanding the differences between recycled and virgin vinyl LVP can help you make smarter purchasing decisions.

Why This Matters

Recycled vinyl offers eco-friendly benefits, reducing landfill waste and lowering carbon emissions. Virgin vinyl, on the other hand, often provides consistent mechanical performance, but its production footprint is higher. For B2B buyers, comparing these options isn’t just about price—it’s about long-term performance, installation efficiency, and sustainability compliance.

Performance and Durability

Both recycled and virgin vinyl LVP are engineered to last. High-quality products can serve 10–25 years in commercial or residential settings, with recycled LVP sometimes matching or exceeding the durability of virgin options due to advanced manufacturing processes. Key performance factors include:

Scratch and Dent Resistance: Both formats feature wear layers that protect against everyday impacts. High-traffic hallways, busy kitchens, and active office spaces benefit from this layer, but larger planks in LVP distribute weight more effectively, reducing denting risk.

Waterproof vs Water-Resistant: LVP cores, whether SPC or WPC, are designed to block water completely. Glue-down LVT may only be water-resistant, performing best with careful installation. For areas like laundry rooms, basements, or mudrooms, selecting a fully waterproof rigid-core option prevents long-term moisture damage.

UV Exposure and Fading: Direct sunlight can fade vinyl floors over time. High-quality recycled or virgin LVP combats UV damage better than standard sheet vinyl, but protective measures such as window films or shades are recommended for rooms with large south- or west-facing windows.

Heavy Load Tolerance: Thicker planks provide better impact distribution. Dragging furniture or moving equipment across a commercial space is less likely to damage LVP than thin tiles, though all vinyl flooring benefits from protective pads under heavy objects.

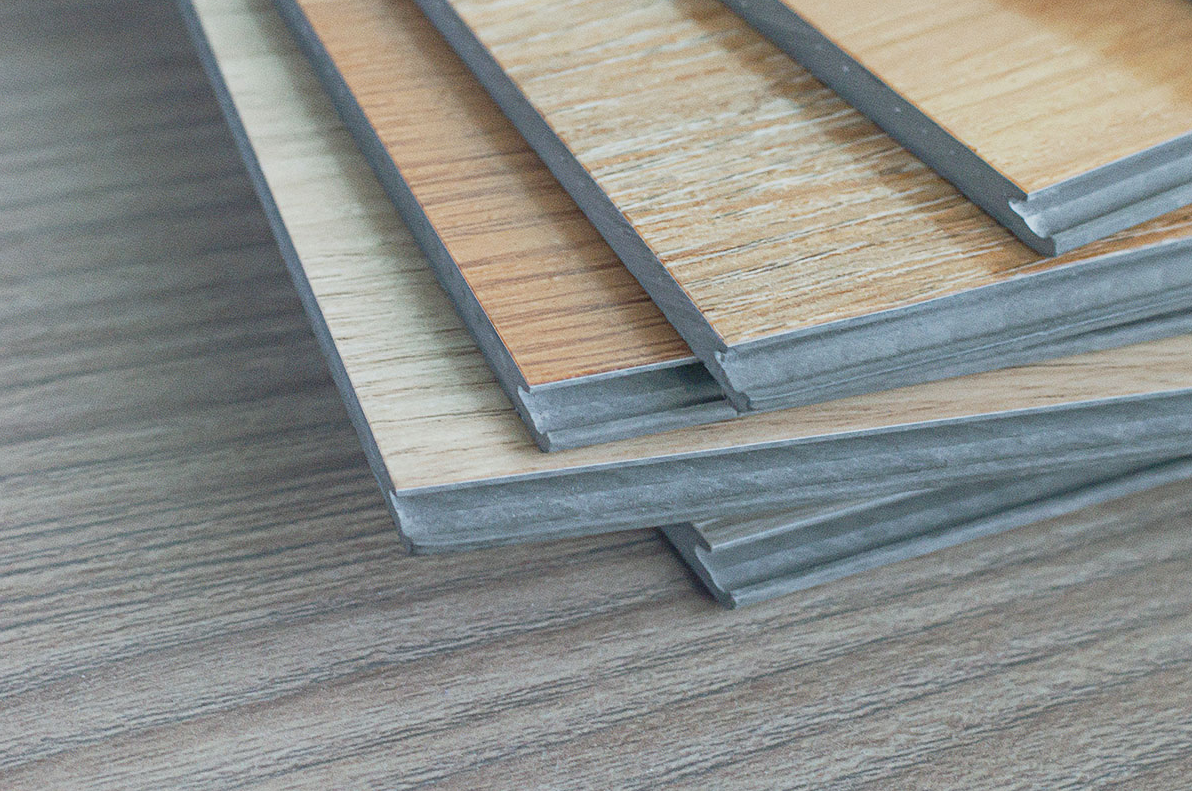

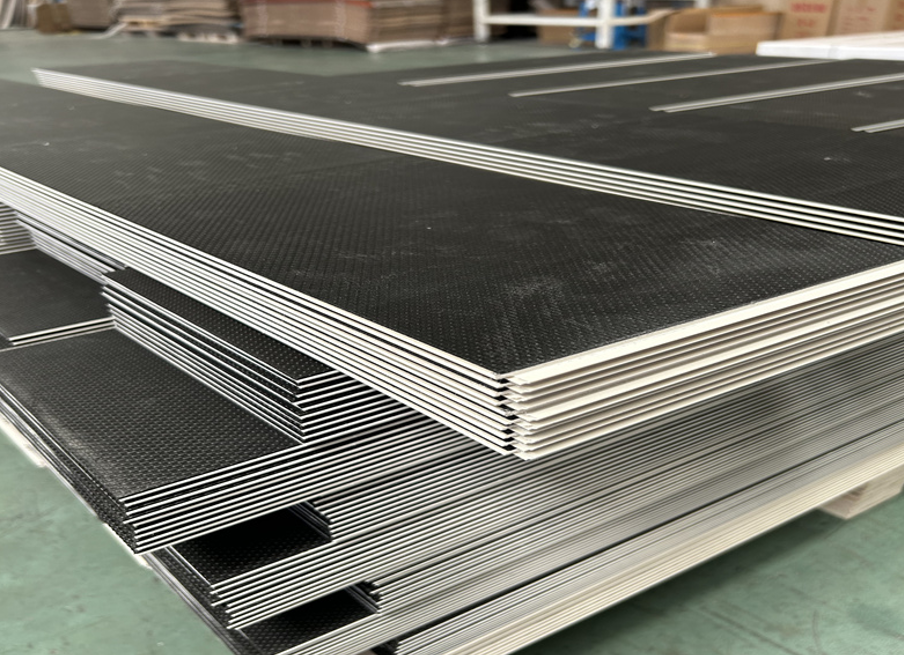

Installation Considerations Installation quality has a direct impact on both durability and waterproof performance. LVP often uses click-lock floating systems, making it faster and easier for commercial installations and reducing labor costs. Glue-down options, while requiring more prep and professional installation, offer maximum stability and moisture protection—ideal for high-moisture or heavy-duty environments.

Environmental Impact

For environmentally conscious buyers, recycled vinyl LVP reduces reliance on virgin plastic, lowering carbon emissions and diverting waste from landfills. However, recycled content alone doesn’t guarantee sustainability. Look for:

Verified lifecycle assessments or ISO 14040 certifications

Transparent VOC emission data to ensure indoor air quality

Third-party testing for phthalate migration or chemical exposure

Virgin vinyl may still dominate in consistent mechanical performance, but careful sourcing and supplier transparency can mitigate environmental concerns.

Choosing the Right Option for Your Project

When evaluating recycled vs virgin vinyl LVP, consider:

Project Type and Traffic: high-traffic commercial spaces benefit from thicker, rigid-core LVP with superior wear layers.

Moisture Exposure: Bathrooms, kitchens, and utility areas need waterproof options; click-lock floating planks work if joints are sealed, while glue-down may provide additional moisture protection.

Sustainability Goals: Recycled LVP reduces environmental impact, but confirm verified testing and lifecycle data.

Installation Resources: DIY-friendly click-lock planks can cut labor costs; professional glue-down installations ensure stability in critical areas.

By assessing technical specifications, environmental data, and installation requirements, you can separate genuine performance from marketing hype. This approach ensures your flooring choice meets durability, waterproofing, and sustainability standards, while aligning with project budgets and timelines.

Takeaway Recycled or virgin vinyl LVP isn’t just a material choice—it’s a strategic decision that affects durability, maintenance, and environmental footprint. For B2B buyers, comparing verified performance metrics, Installation Methods, and environmental certifications will guide you to the right product for your space. Don’t just rely on brochures—look at the numbers, the tests, and the long-term performance evidence.

How to Compare Recycled vs Virgin Vinyl LVP Before You Buy

Before committing to a vinyl LVP purchase, whether for commercial projects or residential installations, it pays to do a structured comparison. A smart evaluation helps you understand performance, durability, and environmental impact—long before installation. Three steps set the stage: exploring key topics, reviewing available studies, and defining clear questions to guide your decisions.

Step 1: Explore Key Focus Areas

Start by listing 3–5 areas that matter for your project. For recycled vs virgin vinyl LVP, these could include:

Differences in chemical composition and safety

Long-term durability and wear resistance

Manufacturing carbon footprint and sustainability

Indoor air quality impact

Lifecycle cost-benefit comparisons

Frame your goal in one clear sentence, e.g.: “I want to evaluate phthalate levels in recycled vs virgin vinyl LVP to see if recycled content affects indoor air quality.” This keeps your assessment focused and actionable.

Talk with a supplier, consultant, or industry expert to check feasibility. They can help you understand available data, practical limitations, and typical project timelines. This step prevents wasted time on questions that aren’t measurable or relevant.

Step 2: Review Available Data and Identify Gaps

Look at 50–100 product datasheets, technical reports, or testing summaries. Track details like product type, sample size, testing conditions, and manufacturer region. This helps you see what’s already known—and what’s missing.

For example, most studies focus on Commercial Applications, leaving a gap in residential performance. Many emission tests occur at room temperature only, ignoring tropical climates. Noticing these gaps helps you focus on areas that truly affect your project.

Summarize your findings clearly: “While 127 studies cover virgin vinyl LVP, only 18 include recycled content, and none compare both under identical conditions. This leaves a major gap in actionable environmental performance data.”

Step 3: Define Practical Evaluation Questions

Turn gaps into actionable questions that guide your project decisions:

How do VOC emissions differ between recycled and virgin LVP after installation?

How does wear layer durability compare under heavy foot traffic?

What’s the lifecycle carbon footprint from manufacturing to disposal?

Benchmark with available data. If initial sources don’t provide answers, refine your scope: focus on specific regions, installation types, or recent production years. This ensures your evaluation is precise and relevant.

By following these steps, you create a clear blueprint for choosing the right vinyl LVP for your needs—balancing durability, safety, and sustainability—before you even place an order.

Understanding the Background: Recycled vs Virgin Vinyl LVP

Before comparing recycled and virgin vinyl LVP for commercial or residential projects, it helps to understand the industry context, available data, and knowledge gaps. A clear background ensures your purchasing or specification decisions are grounded in facts, not marketing hype.

1. Industry Overview

Vinyl flooring accounts for roughly 36% of the $68 billion global resilient flooring market. Environmental regulations are pushing manufacturers to adopt recycled content formulas. Yet questions remain about durability, wear resistance, and indoor air quality. Understanding these factors helps facility managers, designers, and procurement teams make informed choices.

2. What Existing Studies Show

Recent testing highlights differences between virgin and recycled vinyl LVP:

Virgin vinyl LVP shows about 0.15mm wear layer breakdown after 10,000 cycles (Chen et al., 2022).

Recycled LVP reports 0.18–0.23mm breakdown under similar conditions (Martinez, 2023).

No study uses the same methodology for both materials, making direct comparisons tricky.

This snapshot helps buyers see where recycled options might trade durability for environmental benefits.

3. Identifying Gaps in Data

Most lifecycle studies focus heavily on virgin vinyl:

127 studies from 2015–2024 examine virgin LVP in detail.

Only 18 studies cover recycled content LVP.

Zero studies directly compare both using identical testing across manufacturing, installation, use, and disposal phases.

This represents an 86% knowledge gap, leaving many B2B buyers reliant on marketing claims rather than evidence.

4. Why It Matters

Understanding these gaps is crucial:

Building managers need accurate data to select floors that balance sustainability, performance, and cost.

Choosing recycled vinyl without solid evidence may risk durability, increase maintenance costs, or affect indoor air quality.

5. Practical Evaluation Goals

A structured assessment turns gaps into actionable questions for your project:

Measure VOC emissions at 7, 30, and 90 days post-installation.

Compare wear resistance over 10,000 ASTM F1700 cycles.

Calculate lifecycle carbon footprints from production through disposal.

Assess cost-per-year performance ratios for both material types.

6. Expected Trends

Early evidence suggests recycled LVP may provide 15–25% carbon savings during manufacturing, but potentially 8–12% lower wear resistance compared to virgin vinyl. Understanding these trade-offs helps buyers plan for both sustainability and long-term performance.

Tips for Using This Background

Keep overviews brief but informative.

Start broad with industry trends, then focus on material-specific gaps.

Always note sources and summarize key findings in simple terms.

This approach builds trust and guides B2B decisions based on facts rather than promotional claims.

Conclusion

Choosing between recycled and virgin vinyl LVP depends on two main factors: environmental priorities and performance requirements.

-

Virgin vinyl LVP delivers maximum durability, wear resistance, and long-term performance, making it ideal for high-traffic commercial spaces like offices, hotels, and retail.

-

Recycled vinyl LVP emphasizes sustainability and circular economy benefits, reducing plastic waste while still offering good performance for residential or moderate-traffic areas.

Thanks to modern manufacturing, the performance gap has narrowed. Recycled LVP now meets strict industry standards and certifications. To make an informed choice:

Check product specifications: Ask manufacturers for recycled content percentages.

Verify certifications: Look for floorscore, GreenGuard, or similar third-party certifications.

Request samples: Test in your actual space to see texture, color, and durability.

Remember, the most sustainable floor is one that lasts. Virgin vinyl offers a longer lifespan and withstands heavy use. Recycled vinyl supports environmental goals and a circular economy. Your business needs and project context will guide the final decision.

Quick Comparison Table: Recycled vs Virgin Vinyl LVP

| Feature / Factor | Virgin Vinyl LVP | Recycled Vinyl LVP |

|---|---|---|

| Durability | High – best for heavy traffic | Moderate – suitable for normal use |

| Wear Resistance | Excellent – long-lasting | Good – slightly lower than virgin |

| Environmental Impact | Higher carbon footprint | Lower footprint, supports recycling |

| Cost | Typically higher upfront | Often more affordable |

| Lifespan | 15–25 years | 10–20 years |

| Certifications | FloorScore, GreenGuard available | FloorScore, GreenGuard available |

| Best Use | Commercial, offices, retail | Residential, moderate-traffic areas |

| Maintenance | Low, easy to clean | Low, easy to clean |