A Look at Baier’s Flexible OEM Flooring Production for Global Brands

In today’s competitive OEM flooring industry, Baier stands out for its exceptional flexibility, supply chain control, and global capabilities. From sourcing to production and delivery, Baier provides complete support for global brands seeking consistent quality, reliable timelines, and full customization.

Core Strengths of Baier’s OEM Flooring Production

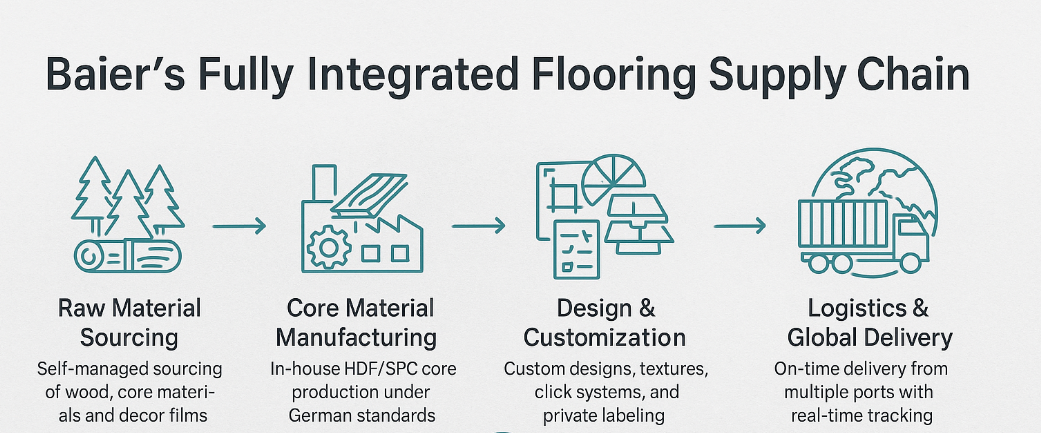

Complete Supply Chain Control

Baier manages the full production chain—from sourcing raw materials to delivering finished flooring products. This vertical integration allows them to ensure stable quality, reduce costs, and eliminate delays. By owning their core material production, Baier provides global partners with predictable lead times and factory-direct pricing, critical for maintaining supply reliability across multiple markets.

Custom Order Capability

The company lets brands order custom flooring. They can meet specific needs for materials, finishes, and local rules. I like that their production lines can adjust to these different requirements, whether for design or regulations, and they can also deliver commercial design solutions for visuals, packaging, and watermarking based on each brand’s needs.

Efficient Worldwide Support and Shipping

Baier helps brands around the world. They offer local production, support in multiple languages, and good logistics. I suggest that their OEM partners get products faster and enter markets more easily. This is because Baier has dedicated warehouses, active distribution, and live supply tracking.

Technical Details and Production Size

Baier’s manufacturing relies on advanced German high-standard production equipment, ensuring precision, engineering consistency, and quality assurance trusted by global partners.

While exact production output figures are confidential, Baier is well-equipped to fulfill large-scale international orders and small custom batches alike. Their modern logistics and export infrastructure ensure efficient worldwide delivery and fulfillment.

Specialized OEM Products

In addition to flooring, Baier also provides specialized OEM components such as underlay and installation accessories tailored for diverse material applications. This flexibility highlights their ability to adapt products across industries including automotive, interior design, and construction.

Real-World Use & Support Benefits

I’ve seen Baier’s flexible system work for clients in the car, building, and interior design fields.

Their production line adapts to new designs or international standards. This lets brands react to market trends or new rules without delay.

Other benefits for brands are quick prototyping, making changes to production as needed, and receiving full after-sales support in many languages.

The company also works with partners on engineering for ongoing innovation. I feel this helps their custom flooring for OEM brands stand out in the market.

OEM/ODM Flexibility: Customization and Order Control at Baier

From my experience, Baier makes the OEM/ODM flooring process very straightforward. They manage their entire supply chain, keep costs low, and have strong worldwide logistics. They control the whole process, from sourcing wood in the forest to making their own core materials. This means they don’t depend on other companies. For partners, this results in consistent quality and better prices. I believe this is a major strength.

Custom Order Capability

The company lets brands order custom flooring tailored to specific materials, finishes, and local regulations. Their production lines can quickly adjust to different requirements for design or compliance.

Full Control Over Production and Design

Baier handles every step—from making the core board to customizing the top design layer. Clients can choose core thickness, wear layer, locking systems (Unilin, Valinge), surface textures (matte, embossed, glossy), color schemes, and private-label packaging. This helps brands stand out globally.

Flexible Order Sizes

Orders start from a standard 20-foot container (typically 1,800–2,600 sqm depending on product thickness), but Baier often accommodates smaller or more specific requests. This flexibility supports boutique batches and large-scale commercial runs alike.

Better Prices and Faster Delivery

Good Pricing: Baier controls its own materials and manufacturing. This helps them lower their costs. They pass these savings on to their partners, which gives you a great advantage in the market.

Fast Production and Shipping: I suggest noting their speed. Standard samples are ready in just 3 to 7 days. Full orders can ship

as fast as 15 Days. This quick service helps you get your products to customers faster and respond to new trends.

Comprehensive After-Sales Support

Baier offers quick prototyping, production adjustments, and full multilingual after-sales support, enabling smooth cooperation and continuous innovation with partners.

| Feature | Laminate Flooring | SPC Flooring | Fiberboard |

|---|---|---|---|

| Appearance Customization | – Wood or stone grain décor paper – Surface embossing: EIR, glossy, hand-scraped, matte |

– High-definition decorative film – Embossing: EIR, matte, glossy – Synchronized texture |

– Laminated surface (custom colors/patterns) – Edge treatments: beveled, sealed, painted |

| Size & Technical Specs | – Length: 800–2200mm – Width: 120–400mm – Thickness: 7–12mm |

– Length: 900–1800mm – Width: 120–228mm – Thickness: 3.5–8mm |

– Length: 1830–5060mm – Width: 1200–1300mm – Thickness: 2–25mm – Density: 600–1300 kg/m³ – Swelling rate: 2%–15% |

| Packaging Customization | – Color boxes, shrink wrap – Branded watermark or logo – Custom labels & wooden pallets |

– Printed boxes, shrink film – Logo stamping, watermark code – Eco-friendly packaging & pallets |

– Bulk or Polymer plastic film packaging |

Expert Opinion:

“Based on my 15 years with OEM flooring makers in Asia, I believe Baier is unique. They offer extensive custom options and also have very efficient production. I have not seen many companies that can do both things so well.

What impresses me most is their quality control. Even with many different custom choices, from surface textures to packaging, the quality stays consistent. I also recommend them for their flexibility.

They can manage a small order of one container or scale up to millions of square meters a year. This shows me they are an experienced manufacturer that can serve the needs of both small and large businesses.”

———— Lau , Senior Flooring Industry Consultant and Former VP of Global Sourcing at International Building Materials Group

Scale, Capacity, and Global Reach of Baier Flooring Production

At Baier, we do things differently in the flooring industry. We offer flexible OEM/ODM services. I believe this gives you full control over your products and how your brand is seen in the market.

Large Production Capacity

While exact figures are confidential, Baier has an impressive manufacturing capacity across multiple flooring categories. The company can produce up to 6 million square meters of PVC and vinyl flooring annually, alongside 15 million square meters of laminate flooring and over 300,000 cubic meters of fiberboard. This scale allows Baier to handle massive orders for global brands, as well as highly customized production runs for niche market clients.

Wide Product Range and Modern Manufacturing

Their facilities produce a complete range including luxury vinyl planks, waterproof and fireproof options, and multiple click-assembly systems.

Strategic Global Presence and Market Growth

Manufacturing hubs in locations such as Zhejiang, China, support access to Asian and global markets. The commercial flooring market is growing strongly, and Baier is well-positioned to capture this growth with a mix of direct manufacturing and international trading.

Commitment to Sustainability

Baier implements circular economy principles, new flooring materials, and modern installation techniques to meet green building standards required by hotel chains, retail groups, and other major clients.

Customer Feedback: “Baier’s flooring solutions offer a great balance between cost-efficiency and long-term value—a key reason we keep coming back.”

From what I’ve seen, our ability to customize puts us on par with top OEM partners in China and ODM firms in Vietnam. We match their low MOQs and custom design options. We also offer excellent supply chain support, all while keeping our prices competitive.

Using our flexible OEM/ODM system, you can build your own unique, high-quality flooring lines. I believe this gives you full control over every detail. It helps your brand stand out and keeps your operational costs in check.

Take Control of Your Flooring Brand — Partner with Baier

If you’re serious about building a flooring line that delivers on quality, flexibility, and global reliability, Baier is the partner to trust. Their integrated OEM/ODM system doesn’t just offer manufacturing—it gives you full control over how your product looks, performs, and reaches the market.

From fast prototyping to tailored packaging, Baier helps you move faster, stand out stronger, and scale smarter. Don’t settle for generic. Build something that truly represents your brand, with Baier behind every step.