Introduction to the Top Laminate Flooring Manufacturers in Brazil

Brazil’s laminate flooring market is growing fast in 2025, driven by strong demand in both homes and commercial spaces. With local brands offering competitive prices and wide distribution, and imported brands bringing advanced technology and premium designs, buyers now have more choices than ever. In my view, five manufacturers stand out as the most popular in Brazil this year.

Each of them has unique strengths—whether it’s market leadership, affordability, innovation, or sustainability—that set them apart in a competitive landscape.

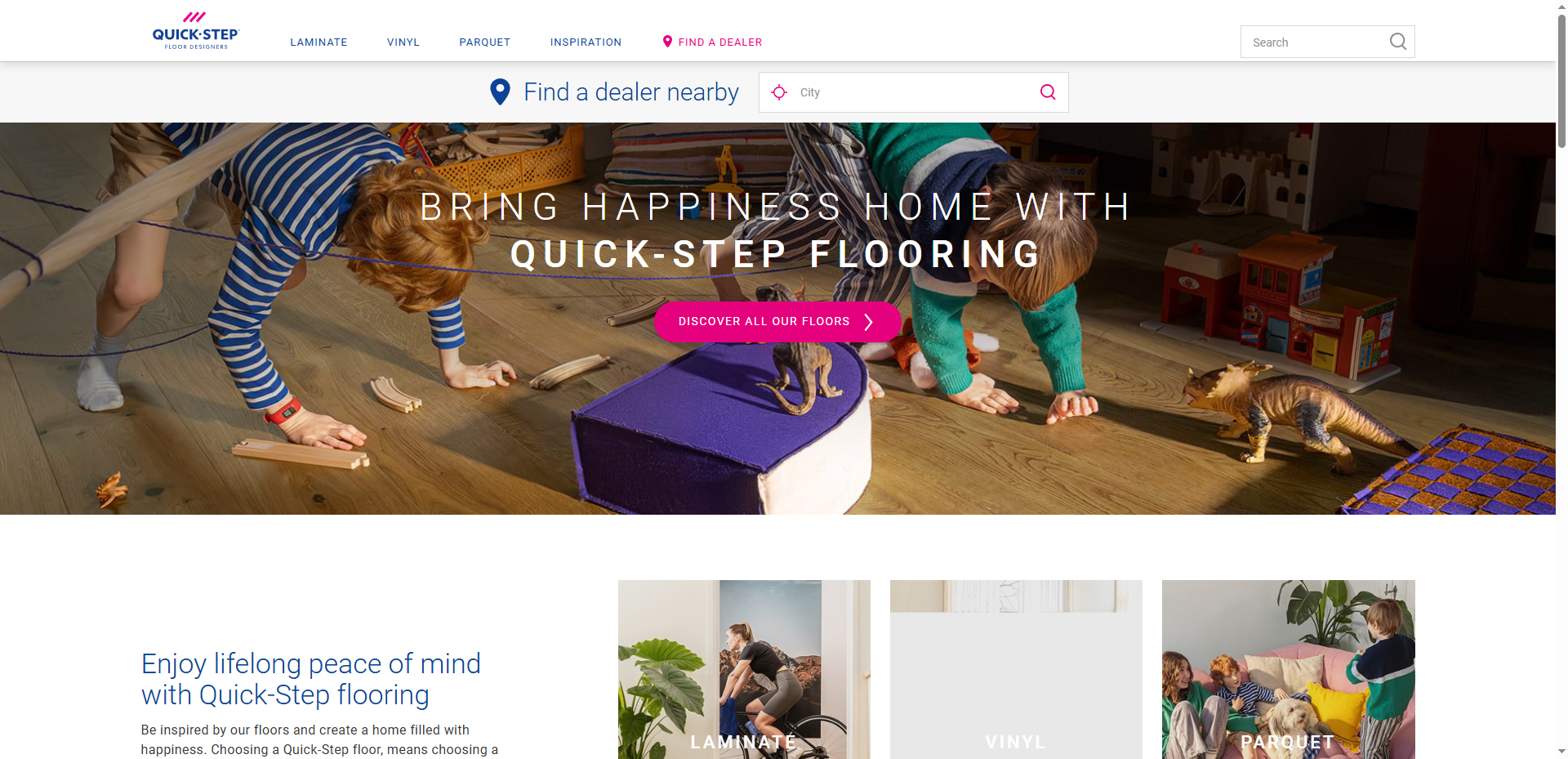

Unilin and Quick-Step: A Big Move into Brazil’s Flooring Market

Major Investment: New Production Facility in Brazil

Unilin, the company behind Quick-Step, is investing €11 million. They are building a new, modern laminate flooring factory in Piên, Brazil.

The factory will open in January 2026. I think their goal is ambitious. They plan to produce up to 10 million m² of laminate flooring each year.

The plant will make new, sustainable flooring. From my experience, making products for local tastes is key. This will make the flooring a better fit for Latin American design trends and easier for people to buy.

Quick-Step Brand Strengths: Quality & Technology

In my opinion, Quick-Step is a well-known brand. Here are some of its main strengths:

I like their easy “click” installation system. It makes DIY projects easier for homeowners. It also cuts down installation time for professionals.

The floors are very durable. They are built for busy homes and businesses. They also have high water resistance, which helps the floor last longer.

Their designs look great. I recommend checking out their realistic wood finishes. They use new press technology to create lifelike textures and offer a wide variety of colors.

Technological Innovations and Sustainability Focus

Unilin’s factories in Europe use top-tier laminate technology:

They just launched a new €30 million production line. It can produce 15 million m² a year. I find it impressive that it’s 30% faster than older lines because it uses AI and robotics.

This tech lets them make several designs at once. It improves precision. It also doubles the wood core depth, so the floors look and feel more like real wood.

They also focus on circular manufacturing. They use sustainable materials, which shows they care about the environment.

Key Quick-Step Product Highlights

The easy click system makes installation simple and attracts more customers.

The floors have high water resistance. They also have tough top layers that are great for high-traffic areas.

They offer a wide range of styles. You can find everything from classic wood looks to modern finishes.

Their sustainable production and use of green materials are great for eco-conscious building projects.

Baier Floor: A Leader in Brazil’s Laminate Flooring Market

Production Power and Market Leadership

I see BAIER FLOOR as one of Brazil’s leading makers of laminate flooring. With a strong base in the country’s wood industry, the company has built a reputation for reliable products that meet local needs. Their Baier brand is well recognized by Brazilian homeowners and businesses alike.

In 2023, Baier Floor operated several major flooring factories across Brazil, with additional capacity in neighboring countries such as Colombia. To me, this shows not only their strong presence in Brazil but also their ability to serve the wider Latin American market.

Brazil’s flooring market is highly competitive, with both local and international players. In this context, I see Baier Floor standing out thanks to its strong distribution network and solid position in both residential and commercial markets.

Sustainability and Environmental Care

I like that Baier Floor makes sustainability a key part of its plan:

In 2023, 63% of the energy they used came from renewable sources. This supports their 2025 Sustainability Strategy.

The company reused 5.4 million m³ of water in its operations during 2023.

I think it’s great that 97.5% of forests owned by Baier Floor are FSC® certified for responsible management. They aim for 100% certification by 2025.

These actions show Baier Floor is a leader in sustainability in Brazil’s flooring industry.

Full Control Over Supply Chain and Raw Materials

Baier Floor manages over 140,000 hectares of planted forests and conservation in China. This allows them to control their whole production process, from forestry to making the final laminate flooring.

Having this full control means they have a steady supply of materials. It also helps them maintain quality and export their products through different company divisions.

Brands, Products, and Market Focus

Their product lineup covers: laminate flooring, vinyl flooring, MDP/MDF panels, ceramic tiles, sanitary ware, and wood boards.

Their Baier brand is a key player in both home and business flooring markets. I believe they are known for new ideas in wood laminate and vinyl designs.

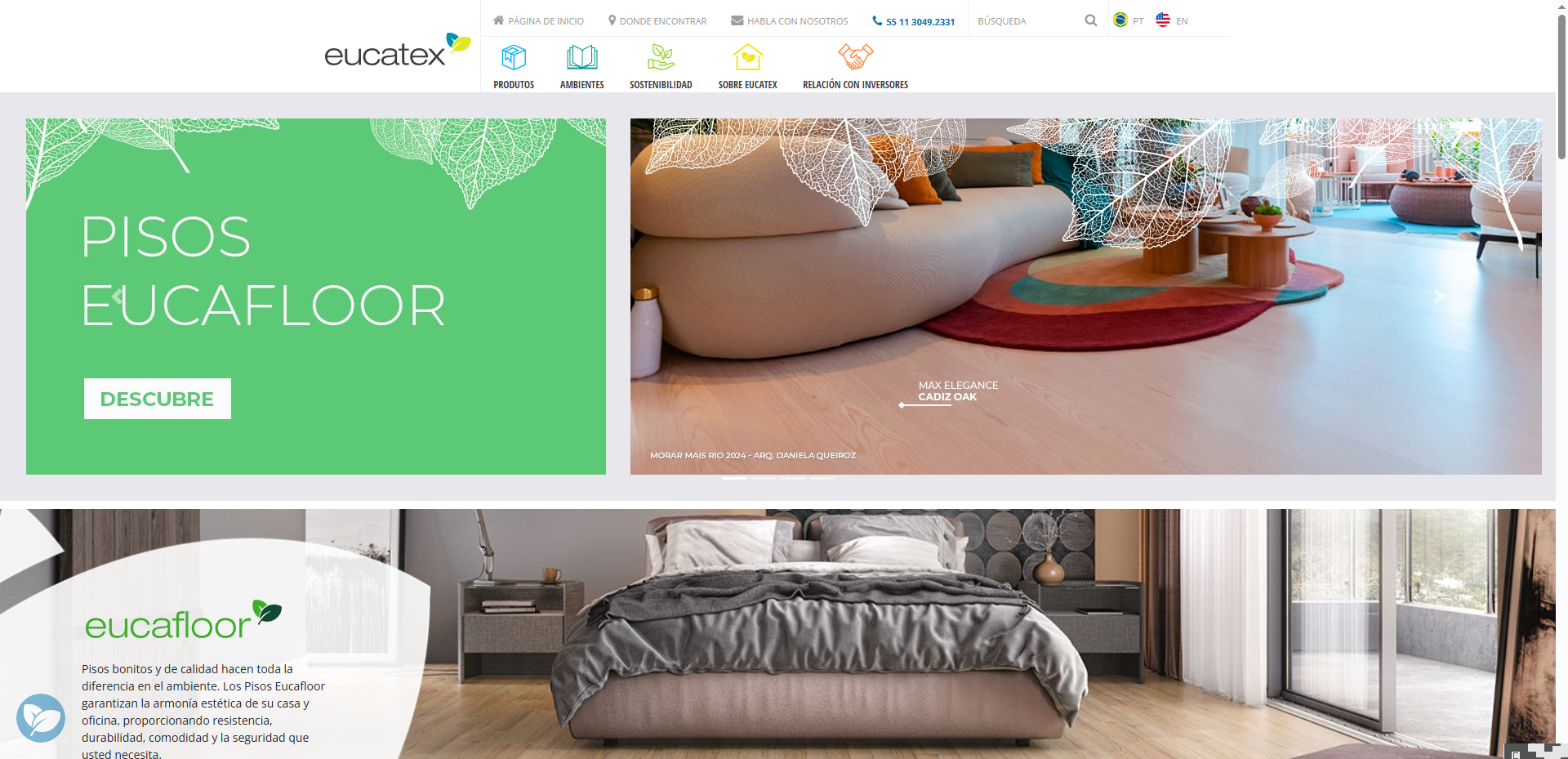

Eucatex: A Leader in Brazil’s Laminate Flooring Market

Eucatex is one of Brazil’s top laminate flooring makers. From my point of view, they have a strong presence both at home and in other countries. The company operates five factories in Brazil and a large subsidiary in Atlanta, Georgia. With more than 3,500 employees, they are a key player in the flooring and construction materials market.

Market Share and Product Variety

Construction materials, including their laminate flooring, account for 44% of Eucatex’s total sales. This shows me how important flooring is to their business.

Sales to the furniture industry and for panel resale make up another 41%. I think this shows they serve a wide range of customers.

I believe Eucatex’s main strategy is to offer different products to different markets. This method helps the company adapt to new demands and keep up with trends.

They adapt very well. In fact, around 20% of their products are changed to suit the tastes of different regions in Brazil.

For example, Eucatex makes special products for the U.S. market, which is their biggest global client. They offer items like slatted sheets, white perforated sheets, and glossy sheets. These are used for garage organization and blackboards.

Key Strengths: Adaptability and Materials

A major advantage for Eucatex is Brazil’s ideal climate for growing raw materials.

This helps Eucatex promise consistent quality and a reliable supply chain. Both are vital for making good flooring.

Their ability to customize 1 in 5 products for different markets gives them great flexibility and shows a real focus on the customer.

Global Reach and Market Leadership

Eucatex’s growth plan includes a big push into global markets, with a particular focus on the United States.

They are always innovating their products. They also focus on meeting new market needs. I think this secures their name as a top, forward-thinking manufacturer in Brazil and the larger region.

Why I Think Eucatex Leads

Eucatex’s size, product flexibility, control over its materials, and market knowledge make it the standard for quality and new ideas in Brazil’s laminate flooring industry for 2025 and beyond.

Grupo Indusparquet: A Top Maker of Brazilian Hardwood Floors

In my view, Grupo Indusparquet is a leading name in Brazil for high-quality hardwood floors. They have over 50 years of experience, bringing fresh ideas to markets in Brazil and worldwide.

Global Reach and Production

The company started in 1970 in Tietê, São Paulo. The founding families have run it for four generations.

They operate three large factories in Brazil and employ more than 500 people.

From my research, their global network is big. They have distribution centers in over 25 countries on five continents.

Wide Range of Products and a Great Reputation

I noticed they offer many types of solid and engineered hardwood flooring. This includes popular Brazilian woods like:

Brazilian Cherry

Santos Mahogany

Tigerwood

Amendoim

Brazilian Chestnut

Their floors are used in famous places. You can find them in The Vatican, Louis Vuitton stores, and Ferrari showrooms. I think this really shows their reputation for luxury and quality.

Using New Technology for Better Floors

From my perspective, they focus on using the latest technology:

BREATH technology: This is a natural air-drying method. It stabilizes the wood over several months. This results in stronger floors that last longer.

LONGLENGTH: They use extra-long planks, which are longer than the standard 48 inches. I find this creates a unique and balanced look in any room.

CLEARVUE: This is a special nine-coat finish. It brings out the natural beauty of the hardwood. It also means less maintenance for you.

A Strong Focus on Quality and the Environment

I appreciate that Indusparquet has strict quality checks before any sale:

They test for scuffs, scratches, impacts, and how well the finish sticks.

This makes sure each product is durable and performs well in tough situations.

The company has a zero-waste policy in its factories. They use all the timber. Any leftover wood becomes furniture or biofuel to power the plants.

They also follow strict Brazilian environmental rules for their forests. In my opinion, sustainability is a core part of how they work.

Portobello S.A.: A Leader in Brazil’s Flooring Market

Portobello S.A. is a top flooring maker in Brazil. It competes well with other leaders like Grupo Indusparquet and Duratex. Together, these companies hold a 35–40% share of Brazil’s floor covering market. This solidifies Portobello’s role as a key player as the industry grows toward 2025.

Company Scale and Market Presence

Headquarters: Tijucas, Santa Catarina

Annual Revenue: More than R$ 1 billion

Production Output: Around 30–45 million square meters each year

Employees: Over 2,600

Export Markets: The company sells to over 75 countries on five continents. I believe this strengthens its position at home and abroad.

Retail & Distribution Network:

25 company-owned stores

133 Portobello Shop franchises

Several Officina Portobello custom product units

Nine distribution centers (seven in Brazil, two in the US) keep the supply chain running smoothly.

Factories: The company runs two factories in Brazil and has added a new U.S. factory.

Product Innovation and Brand Leadership

Design Focus: From my experience, Portobello creates flooring collections that set trends. They are designed for architecture and interior design projects.

Annual Launches: It releases new product lines each year. I like that they focus on beauty, strength, and sustainability to meet what customers want.

Recognition: Portobello is often a Best in Show Finalist at big industry events. This proves its commitment to innovation and quality.

Industry Engagement: The company is an active member of Anfacer, Brazil’s main ceramics association. This involvement allows it to help set industry standards and join top trade shows.

Digital Growth and Strategic Expansion

E-commerce and Digital Marketing: I can see that Portobello invests a lot in its digital strategy. It is growing on e-commerce sites and uses modern digital marketing to find new customers.

Manufacturing Technology: The company has upgraded its factories with new technologies. This helps with efficient, high-quality production and supports green operations.

Global Expansion: The new factory in the U.S. and more distribution centers show its goal for global growth.

Sustainability and Market Trends

Green Products: I suggest looking at Portobello’s flooring, which is designed to be sustainable. This meets the growing need for green materials in Brazil’s strong real estate market.

Market Growth: Brazil’s flooring market is set to grow. It is expected to go from USD 6.9 billion (2024) to USD 19.8 billion (2033). This is a growth rate over 12.4–14% per year. I believe Portobello’s focus on new ideas and sustainability will help it secure a large piece of this market.

Government and Industry Support: The company’s green methods fit with government rules and the move to sustainable building.

My Breakdown of Brazil’s Top Laminate Flooring Makers in 2025

Brazil’s laminate flooring market is growing fast in 2025. I see a lot of competition. There’s a clear split between local and imported brands. Let me show you how the five most popular companies compare:

Strategic Differentiators in 2025

Duratex holds the largest market share. I think they do a great job with both high-end and budget-friendly floors.

Eucafloor uses low prices and an efficient supply chain. This helps them lead the low-cost market segment.

I would recommend imported brands like Baier Floor, Kronotex, and Quick-Step for complex projects. People choose them for their advanced features and better warranties.

Technical, Eco, & Customization Focus: From my experience, winning companies focus on a few things. They get green certifications like FSC and E1. They also adapt products for local buyers and partner with big stores and developers.

Distinct Consumer Segments: Duratex and Eucafloor attract buyers looking for value. In contrast, Pergo, Quick-Step, and Kronotex attract customers who want great design, long life, and top performance.

What Sets Each Top Brand Apart

Duratex: Duratex is the market leader. I like their fresh designs, they are sold everywhere, and they have solid green certifications.

Eucafloor: Eucafloor offers great prices and is available across the country. I feel they give you good quality for the money, especially for the average buyer.

Baier/Kronotex: These feel like luxury imports. They resist scratches well and are very durable. I see them used often in high-end building projects.

Quick-Step (Unilin): People know Quick-Step for its easy click-install system. It also resists water and fits local Brazilian styles well.

Conclusion:

My final take is that Brazil’s laminate flooring market in 2025 is clearly divided. Local companies sell the most flooring. Imported brands do best in the high-end market. To succeed in this growing market, I believe companies need good technology, green certifications, and smart product plans for their target customers.