Leading SPC Flooring Manufacturers & Suppliers in Turkey for Commercial Projects

We’ve structured this listing to give you useful details on each manufacturer. You get real specs, real capacity numbers, real certifications. No fluff.

Each company profile follows the same format. You’ll see location, establishment year, production capacity or scale, technical specs, product offerings, and direct website links. This setup lets you compare suppliers side-by-side. No need to hunt through marketing talk.

We’ve also built a comparison table that shows core metrics only. Capacity is measured in square feet per year. You’ll see key technical specs like density and thickness. Plus warranty terms and standout features like zero-waste systems or solar power.

The selection criteria focus on what matters for sourcing SPC flooring manufacturers and suppliers in Turkey. We look at proven production scale. Verifiable certifications matter too (ASTM, ISO, Intertek Clean Air Gold). Export track records to tough markets like North America and Europe count. So does clear technical data on density, wear layers, and waterproofing.

You’ll find direct contact pathways at the end. No middlemen. Request quotes and technical documentation straight from the source.

Area Floors Inc. (Akgün Yapı)

Area Floors Inc. launched in 2022, but don’t let the recent founding date fool you. This Istanbul-based operation runs a 12,500 m² automated facility. It produces over 3,000,000 m² of SPC flooring and wall panels each year. That’s serious scale for a young company.

The full legal name is Akgün Yapı ve Zemin Kaplamaları San. ve Dış. Tic. Ltd. Şti. They’ve built export ties across more than 20 countries. Europe and North America are their main markets. Buyers in these regions demand top-notch quality.

Product Range and Technical Specs

Area Floors focuses on click-lock SPC flooring. You get options for different project needs. Their IXPE-backed acoustic solutions reduce noise. The herringbone collections add pattern choices. They also make SPC wall panels with sharp surface finishes.

Technical specs matter here. Their SPC flooring comes in 0.5 mm wear layer versions. These work great for heavy traffic zones. The 0.3 mm wear layer options suit homes better. The production follows standard methods. PVC mixes with calcium carbonate and additives. Then automated lines push it through to form the SPC core board.

Certifications and Quality Assurance

Area Floors holds ISO 9001, ISO 14001, and ISO 45001 certifications. These cover quality control, environmental rules, and worker safety. They’ve earned CE marking under EN 14041. Plus, they have floorscore® certification for indoor air quality.

Their Environmental Product Declaration (EPD S-P-0025563) runs through September 2030. It meets ISO 14025:2010 and EN 15804:A2 standards. Every batch goes through their in-house lab. Testing equipment checks mechanical and physical specs.

Location: Cumhuriyet Mah. Firuze Sokak, E-5 Karayolu Üzeri, İstanbul Outlet Park AVM 1. Bodrum Kat, Beylikdüzü, İstanbul

Contact: +90 212 872 90 39 | https://akgunyapi.com/

Baier SPC Flooring

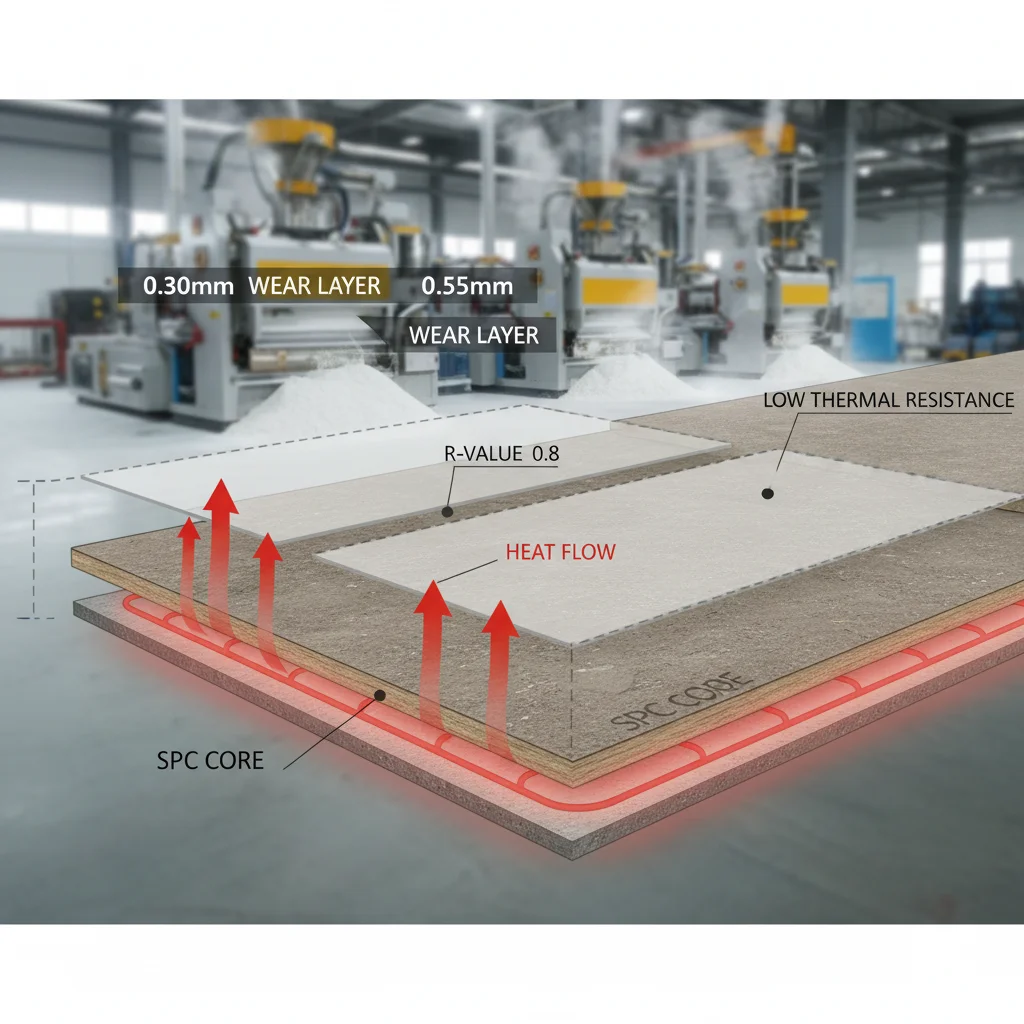

Baier manufactures SPC flooring using a high-density stone–plastic composite formula, centered on a limestone-rich core blended with PVC stabilizers. This rigid core structure delivers density levels exceeding 2,000 kg/m³, placing Baier SPC firmly in the commercial-grade category. The result is excellent dimensional stability—planks resist expansion and contraction even under wide temperature fluctuations.

Baier SPC Flooring is designed for demanding environments. A 0.3–0.5 mm commercial wear layer supports heavy foot traffic and rolling loads. Products are engineered to meet key European performance benchmarks, including abrasion resistance, castor chair durability, color fastness, and slip resistance, making them suitable for retail, office, hospitality, and mixed-use developments.

Technical Performance & Waterproof Structure

Baier offers SPC flooring in multiple thickness options, typically ranging from 3.5 mm to 6.0 mm, allowing project teams to balance cost, comfort, and structural performance. The rigid composite core delivers:

100% waterproof performance

Zero swelling or warping under moisture exposure

Strong resistance to household and light industrial chemicals

Electrical resistance performance supports use in commercial interiors, while the dense core structure ensures long-term stability in kitchens, bathrooms, basements, and utility areas where moisture exposure is common.

Baier SPC flooring is compatible with underfloor heating systems and maintains structural integrity across typical indoor temperature ranges encountered in Middle Eastern and European projects.

Installation Efficiency & Lifecycle Value

Baier SPC flooring uses a click-lock floating Installation System, eliminating the need for adhesives, nails, or permanent fixings. This approach:

Reduces installation time

Minimizes site waste and surface preparation

Allows installation over existing substrates in renovation projects

For contractors and developers, this means lower labor costs and faster project turnover—especially valuable in commercial fit-out schedules.

From a lifecycle perspective, Baier SPC flooring is engineered for long-term use, with an expected service life of 20–25 years in standard commercial and residential applications. The rigid core structure, wear layer durability, and low maintenance requirements significantly reduce total cost of ownership compared with traditional vinyl or laminate flooring.

Supply & Project Positioning

Baier supplies SPC flooring primarily on a project and wholesale basis, with minimum order quantities aligned to commercial-scale applications. Pricing varies based on:

Core thickness

Wear layer specification

Surface design and embossing

This flexible specification model allows Baier to support cost-sensitive residential projects as well as high-performance commercial installations, positioning the brand in the mid-to-upper SPC market segment—offering stronger technical performance than entry-level products while remaining cost-efficient versus premium boutique brands.

Kermit Floor (Kermit Plastic INC)

Kermit Floor builds SPC flooring with decades of polymer work and mold-making know-how. This shapes everything we make. Design details stay sharp. Each production run stays the same. Quality repeats batch after batch. We use precision tooling to improve products, not guesswork.

We make SPC flooring, flexible skirting boards, and wall panels. Each product works with the next. You get a complete system—floors, edges, walls. The skirting boards bend to fit uneven surfaces. No gaps. No ugly corners. This helps a lot in older buildings with crooked walls.

Testing and Standards

Our SPC flooring meets European and North American standards. It beats the minimum in several areas. The material is 100% waterproof. Pet mess, spills, moisture—none of it hurts the planks. Stains from common household cleaners wipe right off. Dropped objects won’t crack it.

We test all raw materials through third-party labs before making anything. Health standards are a big deal for us. Outside labs check our quality marks. We earned Intertek Sustainability Clean Air Gold Certification for our SPC rigid core floors. This proves low VOC emissions. Your indoor air stays clean after you install it.

How We Work and Sustainability

We serve Turkish projects and export markets. Documentation is clear. Stock stays ready. We work straight with distributors, dealers, and project buyers. Our products fit both homes and commercial spaces.

Sustainability means long product life to us. Floors that last longer need fewer replacements. We back renewable energy plans in our factory. Our processes cut waste and save materials during making.

Contact: [email protected] for specs on skirting boards, SPC flooring, and PVC profiles.

ADOFLOOR

ADOFLOOR publishes full EN 16511 test data for every SPC product line. Most factories hide specs or round numbers up. Not here. You get exact wear layer thickness, locking strength measurements, and dimensional stability percentages. This transparency protects your investment.

Their 4mm SPC click flooring comes in two wear layer grades. The 0.30mm version weighs 7,850 kg/m² and handles 23/33 use classes. The 0.55mm heavy-duty option drops to 7,140 kg/m² but jumps to 23/34 classification. Both measure 4.00mm total thickness under ISO 24337 testing. Dimensional stability stays at ≤0.15% under EN-ISO 23999 standards. Temperature changes won’t buckle these planks.

Performance Data That Backs Real Projects

Abrasion resistance differs between grades. The 0.30mm wear layer survives ≥2000 cycles per EN 13329 Annex E. The 0.55mm version doubles that to ≥4000 cycles. Commercial lobbies and retail floors demand this kind of toughness. Residual indentation stays ≤0.05mm across both products under ISO 24343-1 testing. Heavy furniture won’t leave permanent dents.

Impact resistance exceeds 1800mm per EN 13329 Annex F. Drop tools, drag equipment—the surface holds. Light fastness scores 6-7 on EN ISO 105-B02. Sunlight won’t fade colors near windows or glass doors. Slip resistance hits R9 with μ≥0.30 DS under dry conditions. Wet floor safety meets DIN 51130 and EN 13893 standards.

Installation Speed and Acoustic Control

ADOFLOOR’s Drop-Lock Click system cuts installation time by 30% versus traditional methods. No tools needed. No adhesive mess. No squeaking joints after months of use. Planks come in two formats: 177.8 x 1219.2mm covering 2.167 m² per carton, or 228.6 x 1219.2mm at 2.230 m² per carton.

Add the optional 1mm IXPE backing and impact sound drops 21 dB on the 0.30mm version, 19 dB on the 0.55mm grade per EN ISO 717-2. The thicker wear layer alters acoustic properties a bit. ASTM testing with IXPE backing shows STC 52 and IIC 55 ratings. Upper-floor apartments and office spaces gain real noise reduction from this setup.

Health Standards and Underfloor Heating

Formaldehyde levels hit E1 classification—almost zero under EN 717-1. TVOC emissions earn A+ rating per EN 16516/ISO 16000. FloorScore certification SCS-FS-05915 proves low VOC output. Fire rating reaches BFL-S1 under EN 13501-1. These certifications clear the way for regulated markets across Europe and North America.

Both wear layer grades work with radiant floor heating up to 29°C maximum. Thermal resistance measures 0.0160 m² K/W for the 0.30mm version, 0.0177 m² K/W for the 0.55mm option per EN 12664. Heat moves through without damaging the flooring structure.

Trustone SPC

Trustone crushes real stone into their SPC core. You get 70% natural minerals mixed with 30% virgin PVC under extreme pressure. Their Endurance Tech Core process fuses this blend through special extruders at high heat. The result? 2000 kg/m³ density—verified, not estimated.

This density number tells you how much punishment the floor takes before damage shows up. Stone composite at this weight stops dents from dropped tools, rolling equipment, and constant foot traffic. The virgin PVC keeps planks flexible. They handle uneven subfloors without cracking.

Thickness Options Built for Different Projects

Trustone offers five thickness choices: 2.5mm, 4mm, 5mm, 6.5mm, and 7mm. These numbers include the attached IXPE underlayment. The wear layer comes in two grades. Pick 12mil (0.3mm) for homes or 22mil (0.55mm) for commercial spaces. Ultimate Shield UV coating sits on top. This coating blocks scratches, stains, and wear patterns better than standard finishes.

Plank sizes cover standard and wide formats. You get 181.1 x 1219.2mm rectangles for tight spaces. The 228.6 x 1219.2mm size works for most home rooms. Long planks at 228.6 x 1524mm create fewer seams in commercial hallways. Square tiles measure 305 x 915mm. Wall panels stretch to 960 x 2800mm. Production stays precise: thickness varies under 0.50mm, width within ±0.10mm, squareness under 0.20mm.

Acoustic Performance That Tests Real

The attached IXPE pad measures 1.0mm or 1.5mm thick. Average density runs 111.3 kg/m³. Impact insulation hits IIC 73 over drop ceilings. Over 6-inch concrete slabs, it reaches IIC 54. Sound transmission drops to STC 72 and STC 54. European testing shows 19 dB impact sound reduction per EN ISO 717-2. Upper floor installs get noise control without buying separate underlayment.

Trustone earned Intertek Clean Air Gold certification. Their planks beat ASTM and ISO air quality limits. Locking strength tests at 2.77 kN/m lengthwise and 2.64 kN/m across width under EN ISO 24334. These joints hold through expansion cycles and heavy use. Usage rating reaches Class 23 for homes and Class 33 for commercial under EN 16511 standards.

Website: Contact authorized Trustone distributors for current pricing and technical docs.

Turkey SPC Flooring Market Procurement Advantages

Turkey’s SPC flooring market hit USD 27.1 million in 2024. It’s climbing fast—projected to reach USD 93.6 million by 2033. That’s a compound annual growth rate of 14.77% from 2025 through 2033. The broader Turkish floor covering market? Growing at 9.6% through 2030. SPC outpaces it by a wide margin.

This growth delivers real value for buyers. More manufacturers jump into the market. Competition pushes prices down. Quality stays steady or gets better. Big names like Graniser, Anka Toprak Urunleri Sanayi ve Ticaret A.S., Bien Seramik, Okur Zemin, and Usak Seramik Sanayii AS are adding SPC production lines. New factories pop up with modern equipment. Production capacity rises across the industry.

Strategic Location Cuts Your Shipping Costs

Turkey sits between three continents. European buyers skip the long shipping routes from Asia. Middle Eastern and African markets get faster delivery than ordering from China or Southeast Asia. Land trucking across borders beats ocean freight for speed. You get more control over inventory. Lead times drop from 45 days to two weeks.

Turkey has trade deals with the European Union and nearby regions. Customs clearance goes smoothly. Tariffs often favor Turkish exports over products from distant factories. Payment terms? More flexible than Asian suppliers who want letters of credit or full prepayment upfront.

Quality Standards Match European Expectations

Turkish SPC flooring manufacturers and suppliers already meet CE marking rules. ISO 9001 and ISO 14001 certifications come standard. You get products built for European rules from day one. No retrofit testing needed. No customs surprises. The business culture fits Western practices. Documentation is complete. Communication happens in English without translation delays. After-sales support works in your time zone.

Market growth at 14.77% CAGR means opportunity. Jump in now. Supplier ties are still forming. Competitive edges are up for grabs.

How to Select the Right Turkish SPC Flooring Supplier for Your Project

Your project type decides which supplier works best. Homes need different specs than office lobbies or big construction jobs. Match the tech specs to real use, not sales talk.

Match Suppliers to Your Project Category

Buying for a home? Look for pet-safe options and antibacterial treatments. Cold climate? Check if it works with underfloor heating. LUXINZA’s SPC flooring has non-slip surfaces. It comes with thick backing that absorbs sound. You won’t get noise complaints in apartments. Your pets can’t scratch through it either.

Commercial spaces need tough flooring. Offices, retail stores, and busy hallways see heavy use. Water protection matters. Impact resistance matters too. LUXINZA put SPC flooring in a Serbian office. People walked on it every day. The planks still looked new after months of traffic. Find suppliers who show you real projects, not just data sheets.

Big projects need consistent volume. Sirma Hali makes 600,000 m² each month. They use 20 powerful looms. Your bulk order ships on time. The color matches across all batches. Mixed production quality wrecks your build schedule.

Technical Verification Checklist

Wear layer should be 0.3mm to 0.7mm thick. It lasts longer this way. Ask suppliers for EN standard test documents. Website numbers don’t count. You need third-party lab proof.

Density must top 1.9 g/cm³. The SPC core stays stable at this level. Thick backing absorbs sound better. Get physical samples. Weigh them yourself. Do the math before you sign anything.

“100% waterproof” claims need proof. Ask for submersion test records. The planks should survive 24 hours in water. No swelling. No layers peeling apart. Sales promises won’t help you six months later. Moisture damage is expensive.

Environmental Certifications That Matter

FloorScore certification tests 35 CREL VOCs. The limits are strict. Good products stay under 70% of max levels. They get Low Priority status. Area Floors makes vinyl tile in Istanbul. It has FloorScore 2023 certification. It meets LEED v4 rules too. You can use it for green buildings in Europe and North America.

ISO 9001:2015 shows the quality system works. ISO 14001 proves environmental controls are real. EN 16354 sets emission limits for flooring. Turkish SPC flooring manufacturers and suppliers with these papers run better than others.

Factory Audit Metrics

Production size shows reliability. Sirma Hali makes 600,000 m² per month. They handle big contracts easily. Dakot Plastik produces over 120 metric tons of foam underlay each month. These numbers mean steady work and reliable materials.

Equipment quality affects your product. Sirma Hali runs twenty powerful looms. Standards stay the same across all production. Area Floors and Dakot Plastik have big Istanbul plants. Modern machines fill these spaces. Small shops with old gear can’t compete.

Quality control needs records. Auditors pick samples from real production batches. They follow SCS-EC10.3-2014 Section 6.2 rules. Zero NCR (Non-Conformance Reports) is good. Zero NIR (Non-Inspection Reports) is good. Zero OFI (Opportunities for Improvement) issues means tight control. Check emissions records before you commit.

Sample Testing Workflow

Get samples picked by auditors from real production runs. Skip the “perfect” samples suppliers show off. Real batches show true quality.

Test all 35 CREL VOCs against V1.2 limits. Check for Low Priority status. Your indoor air stays clean. You meet building codes worldwide.

Test wear resistance, waterproof strength, and density. Use EN and ISO standards. Compare lab numbers to supplier claims. Numbers don’t match? Walk away.

First-Order Risk Controls

Check certifications every time. FloorScore and ISO papers prove basic quality. No certs? They’re betting with your money.

Order small test batches from audited lots. Test these samples completely. Grow your orders after you confirm performance. You limit losses this way.

Check shipping ability before big orders. Suppliers at trade shows with strong chains handle export papers well. Sireci Group has a global shipping network. No customs delays. No shipping mistakes.

Pick Istanbul exporters who ship 120+ metric tons per month. Their export record shows they know international rules, packing needs, and freight systems. New exporters cause problems you don’t need.

Conclusion

Turkey has become a smart choice for SPC flooring manufacturers and suppliers. You get European quality standards, good pricing, and close access to major markets. The five suppliers in this guide show what Turkey’s flooring industry can do. Area Floors Inc. offers a wide product range. Trustone SPC brings fresh designs.

Your next step depends on what your project needs. Check each supplier’s minimum order amounts. Look at their customization options. Review their shipping to your target market. Get physical samples before you commit to big orders. Verify their CE and ISO certifications too.

Turkish flooring companies keep putting money into R&D and new manufacturing tech. These SPC flooring suppliers in Turkey work as long-term partners, not just one-time vendors. Are you a distributor who needs steady inventory? Or a contractor planning a big installation? The manufacturers here give you what you need to build profitable, lasting business ties.

Start checking them out today. Your ideal Turkish flooring partner is ready.