Visit any flooring supplier. You’ll hear “SPC click flooring” tossed around like it’s common knowledge.

Here’s the issue: many contractors mix up Installation Methods with locking mechanisms. This creates problems. You get miscommunication with suppliers, wrong product orders, and delays on the jobsite.

SPC flooring floating vs click systems? These are two different parts of the same installation approach. Understanding this saves you time, money, and hassle on every project.

Are you a seasoned contractor tired of confusing terms? Or maybe you’re new to SPC installations. Either way, this breakdown clears up the industry jargon. You’ll learn what each system means, how they work together, and which common mistakes waste contractors’ time on the job.

“Floating System” and “Click System” – What Contractors Need to Know

Let’s clear up the confusion. Floating system is how you install—planks don’t bond to the subfloor. Click system is the edge lock that connects planks. Most SPC flooring uses both. Click-lock edges create a floating install.

How Each System Works

Floating installs use no glue between floor and subfloor. Planks connect through tongue-and-groove or click-lock joints. They “float” over underlayment. The whole floor moves as one piece. What’s underneath doesn’t affect it.

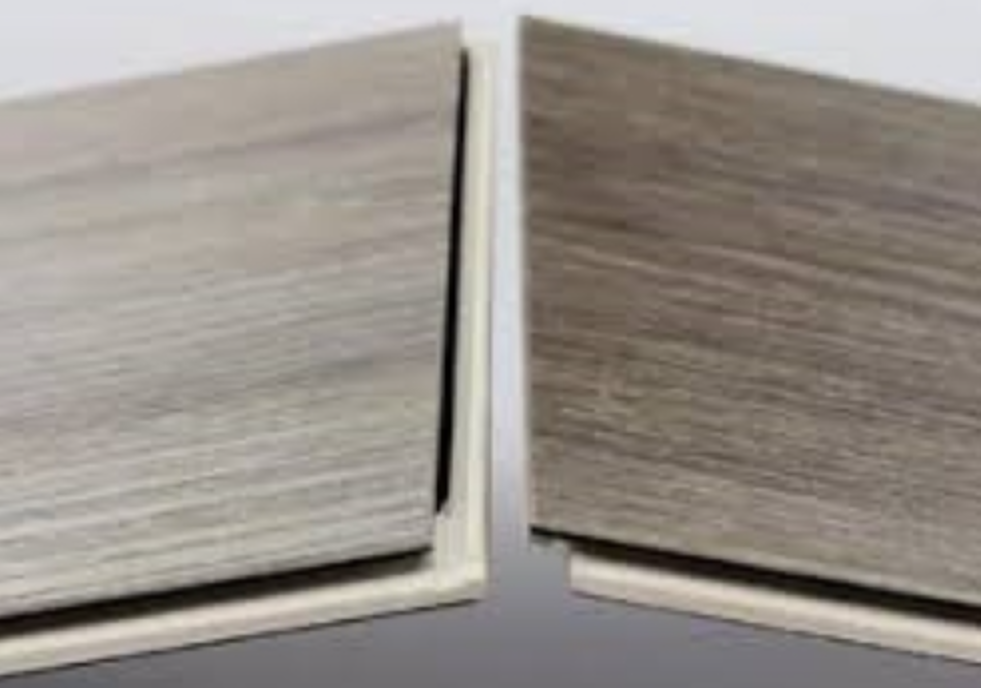

Click mechanisms are the locking tech on plank edges. Angle them. Press down. You hear that snap. This tech creates a floating install. No glue to the subfloor needed.

Your Jobsite Decisions

Subfloor prep varies a lot between systems. Floating click installs work with minor flaws. You can install over existing tile or wood. Just do basic prep. Industry standard? About 3/16″ variation in 10 feet. Glue-down systems need almost perfect flatness. This means lots of skim-coating and leveling.

Underlayment matters for floating systems. Good underlayment gives you that solid feel like a bonded floor. Plus you get sound reduction and shock absorption. Skip it? Your floor sounds hollow. Feels cheap when you walk on it.

Expansion gaps are required for floating floors. Leave space at walls and fixed objects. Your trim hides these gaps. The floor needs room to move slightly. Temperature and humidity cause this movement. Glue-down installs don’t have this issue. Direct bonding gives better stability under heavy rolling loads.

1. Floating Installation System (Method Overview)

The floating method removes permanent glue between your SPC planks and the subfloor. Planks lock together through click systems. They create one unified surface that rests on top of underlayment. This floor can expand, contract, and move as one piece. Temperature and humidity changes trigger this movement.

How the Floating Method Works in Practice

The setup is simple. Start at one wall. Work across the room. Each plank connects to the previous one through tongue-and-groove or click-lock edges. No glue touches the subfloor. The weight of all connected planks keeps everything in place. Furniture and foot traffic add extra hold.

Underlayment is your foundation layer. This thin material sits between subfloor and planks. It’s 2-3mm foam, cork, or rubber. You get cushioning for a solid feel underfoot. It evens out minor subfloor bumps. Plus, it blocks moisture and reduces sound. Good underlayment changes how the floor performs. Skip it or use cheap stuff? You’ll hear that hollow drumming sound contractors hate.

Load distribution differs from glue-down. Weight on a floating floor spreads across multiple planks through the locking joints. The entire floor acts as one flexible sheet. Glue-down installations bond each plank to the subfloor. That difference matters for heavy equipment areas or rolling loads. Floating systems can shift under extreme point loads. Bonded floors stay rigid.

Critical Tolerance Requirements

Subfloor flatness rules are easier for floating SPC installations. Industry specs allow 3/16-inch variation over any 10-foot span. Some makers permit up to 1/4-inch over 6 feet for thicker SPC products (6mm+). This flexibility lets you install over existing tile, vinyl, or wood floors. Minimal prep needed—just basic cleaning and fixing high spots.

Expansion gaps are required. Leave 1/4 to 3/8-inch space at all walls, doorways, and fixed objects like cabinets or posts. SPC expands 0.15-0.20mm per meter with each 10°C temperature change. A 30-foot room can move up to 1/4-inch across its width during seasonal swings. Your baseboard and trim hide these perimeter gaps. They also allow the needed movement.

2. Click System (Locking Mechanism Within Floating Floors)

The click mechanism creates those satisfying snaps you hear during SPC installation. This tech joins planks edge-to-edge. No adhesives needed. Milled profiles on plank edges create mechanical locks. These locks hold floors together under foot traffic and furniture weight. They also handle expansion and contraction cycles.

Modern SPC flooring uses four main click systems. Each one installs differently and performs differently. Your choice affects how fast you install, how strong the joints are, and how long the floor lasts.

Four Click Systems Contractors Should Know

Drop and Lock (Fold-Down) is the basic system most installers learn first. Angle the long edge tongue into the previous plank’s groove. Lower the plank flat. Align the short end. Press or drop down hard. You might need a light mallet tap to engage the short-end lock. The click tells you it’s locked.

5G System speeds up installation with a flexible plastic insert on short ends. Angle and lock the long side first. Then push straight down on the short end. That downward pressure forces the insert to snap into a wedge groove. You hear a clear click. The dual-angled profile locks up and down, plus side to side. This system works well in tight spaces where you can’t angle planks.

I4F System uses a simple one-piece tongue-and-groove edge. No separate plastic inserts. Just angle the long side into place. Press the short side down. Precise milling creates the lock without extra parts. Fewer parts mean fewer things that can break. The one-piece design holds up better in heavy commercial use.

Uniclic System gives you two ways to install for maximum flexibility. The Angle-Angle method: angle the long side into the previous row. Slide the short end into position. Push down for a complete four-sided lock. The Tap-In method: engage the long side first. Then tap the short end with a special tapping block. Use this in doorways or against cabinets where you can’t angle planks. The system builds pre-tension into joints. This stops gaps under thermal expansion.

Performance Differences That Matter on Jobs

Lock strength changes a lot between systems. Uniclic creates deep core engagement with constant tension on all four edges. This stops horizontal pull in busy commercial spaces. The 5G system’s drop-lock gives you strong initial hold. That audible click confirms full engagement—helpful for training new crew members. I4F’s one-piece design gets rid of the fragile inserts found in some 5G versions. The plank core itself gives you durability.

Installation speed depends on method and crew experience. The 5G push-down action is fastest for large open areas. One quick motion per plank. I4F and Uniclic angle-press methods take a bit longer but give you stronger joints. Uniclic’s tap-in option saves time in complex layouts with lots of obstacles.

Gap control starts with milling precision. All four systems use tight manufacturing tolerances to minimize visible seams. Uniclic’s pre-tension fights gaps during seasonal movement. The 5G and I4F systems need proper initial installation and quality underlayment to prevent gaps.

Installation Best Practices

Always angle and connect the long side first. This is standard across all click systems. Then address the short end based on your specific system. Use a scrap plank section and rubber mallet for gentle tapping on end joints. Never strike planks with the hammer. Hammer blows fracture the click mechanism or chip edges.

The floating nature means these interlocks plus underlayment hold everything in place. No glue. No nails. The click system handles all structural loads through mechanical engagement alone. Quality click mechanisms handle the expansion and contraction that floating floors go through. They flex a bit during temperature swings. Then they return to locked position without creating gaps or stress fractures.

3. Common Jobsite Errors

Contractors waste thousands of dollars each year on SPC flooring mistakes. These same errors happen again and again on jobsites. The problems? Confusion between floating methods and click lock systems. Your crew installs the product wrong. Clients complain. You pay for materials and labor to fix it.

Mixing Up Installation Terms During Orders

The biggest mistake? Ordering “click flooring” but needing specific underlayment. Or ordering “Floating floor” without checking the click system type. Suppliers ship products your crew can’t install right. You lose days waiting for correct materials.

Wrong product specs happen often. Contractors assume all SPC click systems work the same way. A crew trained on 5G drop-lock systems can’t handle Uniclic angle-tap methods. Installation slows down. Joints don’t lock right. Gaps show up within weeks.

Underlayment gets skipped or mismatched. Contractors treat floating click floors like glue-down. They think the rigid core alone gives enough support. Wrong. SPC floating installs need 2-3mm underlayment. Skip it? The floor sounds hollow. Clients notice right away. The floor drums under foot traffic. Shock absorption? Gone. Small subfloor bumps show through planks.

Subfloor Prep Shortcuts

Contractors trained on glue-down systems often over-prep for floating SPC. They spend hours skim-coating subfloors that don’t need it. The 3/16-inch tolerance over 10 feet allows small variations. You waste time and money making floors flatter than needed.

Inexperienced crews have the opposite problem. They ignore high spots. They think floating floors fix everything. Sticking-up nails, dried glue chunks, or debris over 1/8-inch create pressure points. Click locks crack under these loads. Planks rock underfoot. The entire floor gets stress fractures within months.

Moisture testing gets skipped on concrete slabs. Contractors think SPC’s waterproof rating means the subfloor doesn’t matter. Vapor above 5 lbs/1,000 sq ft over 24 hours causes glue failure in hybrid installs. Pure floating systems also have problems. Odor issues and mold grow in trapped underlayment without moisture control.

Expansion Gap Failures

Not leaving enough space at edges is one of the most common floating floor mistakes. Your crew installs tight to walls. Temperature changes happen. The floor expands. Planks buckle in the center. They have nowhere to go. You rip out entire sections to fix what 3/8-inch gaps would have stopped.

Fixed obstacles create problems. Installers don’t leave expansion space around kitchen islands, toilet flanges, or doorframes. The floating floor needs to move on its own. Lock it down at any point? You create a stress spot. Planks crack at those points during seasonal expansion.

Transition strips get installed wrong. Contractors nail T-moldings through the SPC into the subfloor. This breaks the floating system. The floor can’t move. Gaps open at seams. Correct install uses track systems. These hold transitions without going through the floating floor surface.

Contractor Takeaway

SPC flooring floating vs click systems – these are two parts of one install method, not rivals. Floating means the floor sits on the subfloor without attachment. It moves freely. Click refers to the edge-locking system that joins planks. Learn this difference. You’ll cut ordering mistakes, train crews faster, and stop expensive rework.

Write clear material orders. List the install method (floating) and the click type (5G, I4F, Uniclic, or drop-lock). Suppliers send the right product. Your crew arrives with proper tools and training. A $15,000 home job can lose $750-$1,500 in profit from wrong orders. You pay for return shipping, restocking fees, and double labor.

Add underlayment to every floating SPC quote. Good 2-3mm underlayment runs $0.15-$0.30 per square foot. Skip it to save cash? Clients hear hollow drumming. They call you back for fixes. That callback kills your profit and hurts your name.

Set clear subfloor prep rules. Floating SPC handles 3/16-inch variation over 10 feet. Train crews to this standard, not the stricter glue-down flatness rules. You save 2-3 hours per 500 square feet. No need for extra skim-coating. That’s real savings on bigger jobs.

Keep expansion gaps at all fixed points. Use 1/4 to 3/8-inch spacers at walls, doors, and obstacles. Put this on your crew checklist. Miss one gap? Buckling repairs cost more than the whole original install.