Modern offices need furniture that saves money, adapts easily, and helps the planet. Particle board delivers all three. That’s why it’s moved from cheap option to smart choice for today’s workspaces.

Particle board now does much more than basic desks. You’ll find it in acoustic walls that help people focus. It powers modular workstations that change setup in minutes. Better manufacturing has made this material work in tough commercial spaces. Surface treatments are stronger. Structural design is smarter.

Furnishing a startup space? Upgrading your corporate office? Particle board has properties you’ll want to know about. It’s easy to machine. The density stays consistent. Plus, it’s better for the environment than many alternatives. These features change how you can approach office design.

We’ll look at eleven specific ways particle board performs in real offices. Some of these uses surprise even experienced facility managers. Organizations that care about durability pick this material. Those who need design flexibility choose it too. You’ll see why it makes sense for serious projects.

Content Framework for “Innovative Particle Board Applications In Modern Office Furniture”

The particle board market keeps growing. Look at the numbers: USD 4.05 billion in 2024 to USD 6.12 billion by 2035. That’s a 4.2% growth rate each year. Another forecast shows USD 11.08 billion rising to USD 22.16 billion by 2033. This 6.5% climb shows real buyer demand.

Furniture uses lead this market. They take over 50% of the share. Plus, they grow fastest at 6.3% each year. Office spaces push this growth. U.S. office furniture spending goes from USD 17 million in 2025 to USD 26 million by 2034. Home office spaces grow even faster. They jump from USD 41.21 billion to USD 58.63 billion between 2026 and 2031.

Regional Performance

North America performs well. The particle board market there reaches USD 1,015.8 million by December 2025. Furniture making and construction drive this growth. Asia-Pacific grows faster. China and India lead with their ready-made office furniture sectors.

Executive Desks and Management Workstations

Particle board executive desks control corporate buying in the $800 to $2,000 range. This price gets you L-shaped setups with pre-laminated surfaces. These surfaces resist scratches and moisture better than untreated wood.

Standard sizes run 72 to 84 inches long. You can fit dual monitors and still have space for documents. Width ranges from 30 to 48 inches. Height stays at 28 to 30 inches for fixed models. Sit-stand versions adjust from 22 to 48 inches. Electric motors handle 220 to 350 pounds.

Material Performance Tiers

Particle board ranks in Tier 2 with quality fiberboard. It beats MFC and MDF in Tier 3. Solid wood takes Tier 1 but costs three to five times more. Custom logos need 20 to 50 units minimum. Color matching takes 50 to 100 pieces.

Weight capacity counts for tech-heavy workstations. Particle board tops hold 100 to 150 pounds. That handles multiple monitors, docking stations, and standard office gear. Steel frames boost capacity to 300 to 500 pounds. Solid wood tops support 200 to 300 pounds. You’ll need to oil them every six to twelve months.

L-shaped designs use corner space well with 60 to 72 inches per leg. U-shaped setups give you 180 inches of total workspace around the edges. Both need bigger offices. L-shapes need 12 by 12 foot rooms minimum. U-shaped setups need 14 by 14 foot spaces.

Particle board desks last five to seven years with moderate office use. Budget lines offer one to three year warranties. Commercial-grade particle board comes with five to ten year coverage. Metal frames last longest at 20 to 30 years.

Modular Workstation Systems and Collaborative Spaces

Particle board drives the modular office shift happening now. The modular furniture market grows from USD 12.5 billion in 2026 to USD 20.3 billion by 2031. That’s 7.2% growth each year. Workstation demand moves faster—USD 80.5 billion to USD 154.8 billion by 2033 at 9.8% per year.

Density grading helps particle board fit collaborative spaces. Low-density boards at 400 to 600 kg/m³ make lightweight dividers. These panels absorb sound above 0.6 NRC. Teams can move them fast for quick changes. Medium-density boards at 600 to 800 kg/m³ hold desktop setups. They carry 50 to 100 kg per square meter. This supports multiple screens and shared tools in busy areas.

Quick Assembly Systems

Tool-free connectors let you swap panels in under five minutes. Modular frames adjust from 60 to 120 centimeters tall. Pin-locking makes height changes easy. Stackable dividers go from 120 to 180 centimeters. Teams can reset entire layouts in under one hour. Old systems take one to three days for the same job.

North America holds 38% of the market in 2026. Asia-Pacific grows fastest. Small and mid-size firms in India, China, and Japan use modular setups. Products like Lenovo ThinkStation P2 and P3 lead this shift. These workstations match with particle board furniture for tech and design teams. Thirty-five percent of tower workstations feature modular, upgradable builds for CAD and 3D tasks.

The ROI shows real results. Sixty-five percent of companies hit or beat their automation targets with modular systems. Seventy percent work with Windows-compatible team software.

Smart Storage and Filing Solutions

Filing cabinets built from particle board now ship with IoT sensors and remote access controls. The smart storage market hit USD 67.46 billion in 2026. It climbs to USD 112.9 billion by 2035 at 5.9% growth each year. These aren’t your old metal filing systems. Modern units track access. They monitor climate. They connect to company portals 24/7.

Particle board makes tech integration simple. The material machines well for sensor mounts and cable routing. Manufacturers cut precise openings for smart locks. No splitting. No cracking. Climate-controlled units protect electronics, artwork, and sensitive documents. Temperature stability matters here. Particle board’s consistent density maintains internal conditions better than metal cabinets. Metal conducts heat. Particle board doesn’t.

Mobile and Modular Filing

Portable storage systems use particle board to cut weight. These mobile units move between workstations as teams shift. The portable storage market grows from USD 55.2 billion in 2025 to USD 87.1 billion by 2035. That’s 5.2% growth each year.

Large enterprises push this change. They hold 61.57% of cloud storage adoption in 2026. BFSI sectors take 23.00%. Public sector claims 18.73%. Physical storage needs to match digital speed. Particle board filing solutions give you that speed and flexibility at scale.

Acoustic Management Applications

Noise kills productivity. Open offices make it worse. Particle board acoustic panels cut sound levels by 15 to 25 decibels in office spaces. The global acoustic panel market shows strong demand—USD 8.6 billion in 2025, climbing to USD 16.4 billion by 2035. That’s 6.7% growth each year. Business and office buyers drive this surge. They hold 33.6% market share in 2025 and grow at 7.1% each year through 2035.

Particle board works because density controls sound. Medium-density boards absorb frequencies from 500 to 2,000 Hz. That’s where human speech sits. IT offices and business parks add these panels to walls and ceilings. New buildings include them from the start. LEED, WELL, and BREEAM certifications now require noise control metrics. You can’t skip this anymore.

Mineral wool panels with particle board cores hit USD 3.4 billion in revenue for 2025. These fire-rated, water-resistant systems grow at 7% per year. They meet China’s tough fire safety and sound blocking standards. Companies like BNBM use eco-materials. These materials pass both performance and green tests.

Sound Level Performance

Real-world tests show what works. Gulf of Mexico office sites hit median sound pressure levels of 104.1 dB in low frequencies up to 200 Hz. Alaskan Arctic offices drop to 77.9 dB with proper panel setup. American Samoa and Caribbean sites keep the most steady levels—standard deviation stays between 2.5 and 4 dB. Particle board panels steady these numbers. They cut variation. Teams focus better with steady background noise.

Sustainable Office Furniture Solutions

The U.S. sustainable furniture market pulls in USD 13.39 billion in 2026. It climbs to USD 17.31 billion by 2031—5.27% growth each year. Particle board applications fit this shift well. They use recycled wood fibers. Less waste comes out during manufacturing. They cost less than solid wood alternatives. Companies hit LEED and WELL certification targets. Budgets stay intact.

Chairs drive the biggest revenue share at 39.45% in 2025. Office replacement cycles push this number. Tables grow fastest though—6.42% CAGR through 2031. Tool-free repair systems make them last longer. Modular tops help too. Reclaimed wood and FSC-certified materials take 34.60% of 2025 sales. Bamboo and renewable grasses grab 6.66% annual growth. Bamboo matures in five years. It matches steel in strength tests.

Commercial Adoption and Certification

Commercial offices grow at 5.98% CAGR targeting LEED and WELL points. Modular desks use particle board tops. They pair with recycled aluminum legs. B2B project channels expand at 5.58% each year. Buyers ask for 3D models with EPDs—environmental product declarations. GSA’s Buy Clean initiative logged over 17,000 EPDs by mid-2024. This creates opportunities for recycled metal frames. Bio-based foams work too. Low-VOC particle board finishes round out the options.

Federal procurement rules now favor recycled content. That adds 1.1% to market growth. Consumer awareness adds another 1.3%. Millennial and Gen Z buyers push FSC and Greenguard certifications. That’s worth a 1.0% CAGR lift. Municipal recycling programs in California, New York, Massachusetts, and Washington contribute 0.8% growth.

Wood holds 61.30% market share in 2026. Carbon-smart processing makes it work. IKEA’s Mittzon line from 2025 shows how. Wood fiber construction brings natural elements into offices at scale.

Reception and Client-Facing Furniture

First impressions close deals before meetings start. Reception furniture built with particle board gives you that polished look. No premium wood price tag. The global reception furniture market pulls USD 5 billion in 2025. It jumps to USD 8 billion by 2033 at 6% growth each year. Wider projections show USD 70.46 billion in 2026 climbing to USD 86.73 billion by 2029.

Corporate offices drive 44% of contract furniture purchases. That’s USD 70.2 billion in total 2025 sales. This segment grows at 5.9% toward USD 123.2 billion by 2035. Companies want reception areas that show credibility. Particle board makes this happen at scale. IKEA, Steelcase, Haworth, and MillerKnoll lead the market. They pair particle board cores with high-pressure laminates. Surfaces resist coffee spills and everyday wear. Guests never spot the engineered core beneath.

Premium Design Without Premium Cost

High-end buyers in North America and Europe push design-focused pieces. Particle board lets makers add custom veneers and edge banding. Reception desks run 72 to 96 inches wide with curved fronts. Tech integration became standard in 2022. Built-in charging stations and digital display mounts thread through pre-routed particle board panels. No visible cables. Clean sight lines.

Upholstered seating hits USD 51.5 billion in 2025 revenue. It grows at 5.9% each year through 2035. Particle board frames support commercial-grade foam and fabric. Modular systems from Haworth and Steelcase reconfigure in minutes. Hybrid work patterns change lobby traffic. Furniture adapts just as fast.

Offline distribution holds 80.9% market share in 2025. Buyers want to test reception furniture in person. They check surface strength. They measure desk height. Asia Pacific takes 41.62% of office furniture share in 2025. Growth there focuses on cost-smart particle board that still photographs well for client presentations.

Breakroom and Pantry Applications

Particle board creates the setup that keeps office pantries running. Average company spend hit $70,035 in Q2 2025—up 8.4% quarter-over-quarter and 13% year-over-year. That money goes into storage cabinets, shelving units, and countertops that handle everyday wear. Particle board makes this scale work. You skip commercial kitchen budgets.

Bars take 9% of spending. Chips and crackers grab 6%. Still and sparkling water claims another 6%. These items need organized storage. Particle board shelving systems hold weight—50 to 100 kg per linear meter for medium-density boards. Adjustable shelves let you stack inventory as product mix changes. Sodas grew 150% year-over-year. Deli items jumped 112%. Your storage adapts or you run out of space.

Countertops handle prep work and microwave stations. High-pressure laminate over particle board cores resists moisture from lunch prep. Sealed edges stop water damage. Companies average $8,645 per month per office on food programs. That volume needs surfaces that clean fast and last years.

Seventy-eight percent of employees say food access makes them feel valued. Break room upgrades return up to 150% in employee retention. Particle board keeps renovation costs low. This justifies the investment.

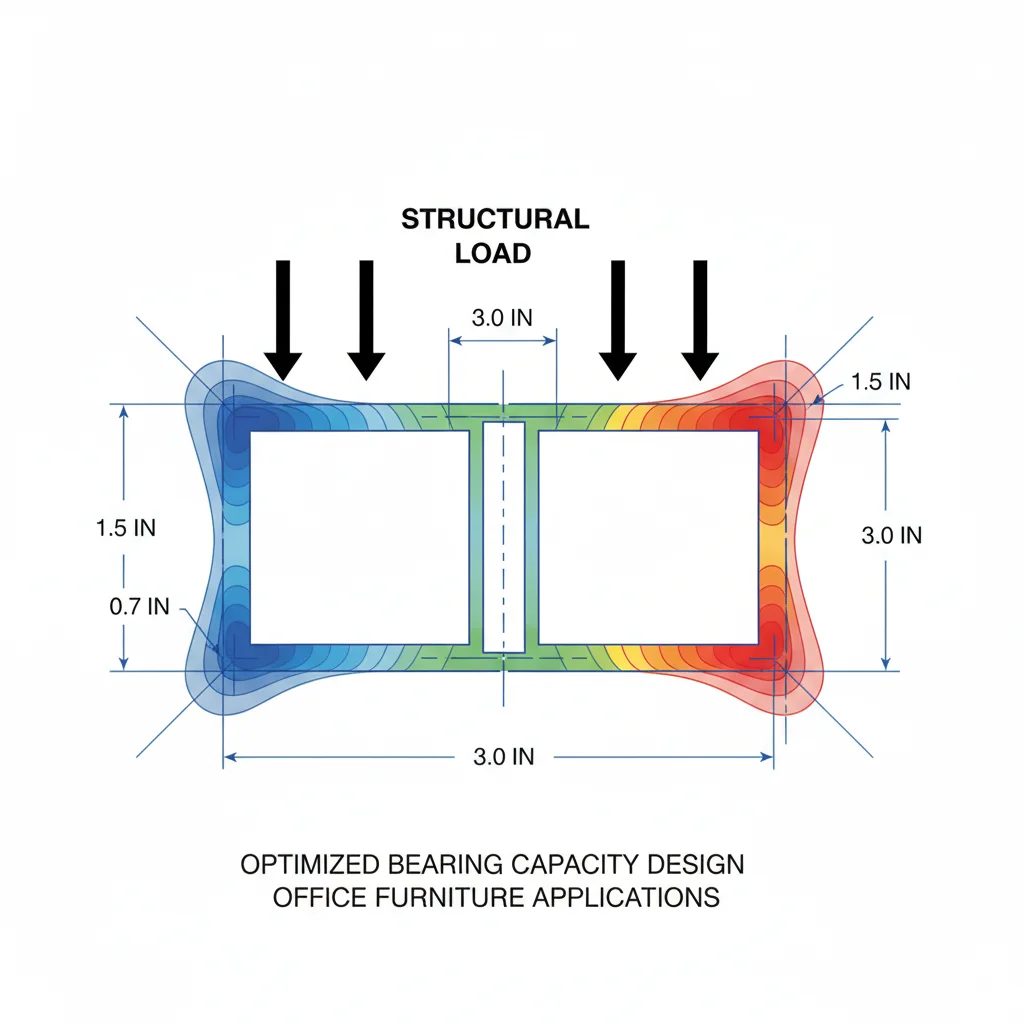

Load-Bearing Capacity Optimization

Precise engineering makes particle board structures perform better than expected. Two-cell box girder setups boost bearing capacity by 20%. No extra weight needed. Local stress modeling creates this gain. Maximum deflection stays within 4% deviation. Tests against FEM and ANSYS benchmarks prove this. The numbers confirm what designers know—smart geometry works better than adding more material.

Multicell box girder designs handle more load than traditional single-cell systems. You get more support per kilogram of material. Buckling resistance goes up. Stress spreads through multiple paths. No single point of failure exists. The structure bends in expected ways under different loads.

Structural Constraint Mathematics

Maximum stress constraints use simple formulas. Stress equals force times length divided by four times section modulus. Section modulus must be at or above force times length divided by four times allowable stress. Deflection follows the same logic. Moment of inertia must meet or beat force times length cubed divided by 48 times elastic modulus times allowed deflection. These equations work in real life. They show what particle board furniture can support in actual offices.

Anisotropic nodes in shear wall uses reach 7.6 MPa maximum shear strength. Optimization algorithms run 160 minimum cycles to find stable answers. The system checks 4,500 best strategies for different load cases. Anti-overturning ratios drop a lot—0.45 for wind loads and 0.13 for seismic events. Particle board structures handle side forces better. Engineers just need to account for directional material traits.

Topology optimization cuts computing time. Accuracy stays high. Simplified damage models create topologies that match complete nonlinear analysis results. Efficiency holds steady. Design teams get quick answers that pass testing. This speeds up product development for load-critical particle board uses in desks, storage systems, and modular walls.

Customization and Rapid Manufacturing

Custom manufacturing changes how particle board furniture gets to offices. The market grows from USD 939.7 billion in 2024 to USD 1,356.9 billion by 2031. That’s 4.7% growth each year. Rapid prototyping adds another 1.9% annual boost across industries. Particle board uses benefit from these shifts.

CAD/CAM integration powers this speed. Design files go from concept to cut in hours, not days. CNC machines just need raw particle board sheets on-site. No precut stock sits in warehouses. Last-minute changes happen without wasting materials. A client wants logo placement moved three inches left? Done before lunch. Old methods took days for the same edit.

AI and cloud systems connect production across continents. Siemens proved this by linking Germany and China factories. Quality control catches defects as they happen. Machines get fixed before breakdowns delay orders. Your custom conference table ships on time. No waiting on parts that broke down last week.

On-Demand Design Flexibility

Hybrid manufacturing mixes 3D printing with CNC cutting. Edge profiles that used to need five setups now need two. Replacement parts print in less time than warehouse shipping. Nike’s NIKEiD model shows how networked production handles custom orders at scale. Customers add personal touches. Systems route orders. Factories make them without slow handoffs.

Eighty percent of executives put twenty percent or more of budgets into smart manufacturing for 2026. Twenty-two percent plan physical AI robots—up from nine percent last year. Particle board furniture makers use flexible tech for small custom batches. Product platforms speed up market launches. Sales teams, engineers, and factory floors work through shared systems. Customer data shapes designs before you build prototypes.

Long-Term Durability in Commercial Settings

Commercial particle board furniture lasts longer than most people think. Spec it right and you’ll see the difference. Office desks and storage systems built from quality particle board run eight to fifteen years with daily use. That beats the industry assumption of five to seven years. The difference? Density grade, surface treatment, and edge sealing—not the base material itself.

Medium-density particle board at 600 to 800 kg/m³ handles commercial loads. Desktops support 50 to 100 kg per square meter. Filing cabinets handle drawer slides that open and close 10,000 cycles before showing wear. Compare this to building systems. HVAC units need replacement every eight to twenty years. Roof surfaces last fifteen to thirty years. Your particle board workstations sit in the middle of that range. They’re not structural steel at 100-plus years. They don’t need to be.

Maintenance Requirements vs. Building Systems

Particle board furniture needs little work. Wipe surfaces clean. Check fasteners once a year. Tighten loose screws before they strip threads. That’s it. No tuck-pointing like brick veneer at seventy years. No EPDM roof membrane replacement at twenty-five years. Office furniture maintenance costs stay predictable. Budget fifteen minutes per workstation each quarter. Multiply by unit count. You’ve got your labor estimate.

Surface damage happens. Coffee spills. Chair arms scrape desk edges. High-pressure laminate repairs in minutes with color-matched filler sticks. Veneer chips need edge banding tape and a heat iron. Both fixes cost under fifty dollars in materials. A facility manager handles this without calling contractors. Building envelope repairs don’t work that way. Aluminum siding lasts twenty-five to forty years, then you’re looking at five-figure replacement projects.

Location changes the numbers. Coastal offices with salt air see metal components corrode faster. Particle board stays stable. High-humidity climates need sealed edges and moisture-resistant cores. Specify this upfront. The upgrade costs ten to fifteen percent more. It prevents the thirty percent replacement rate humid environments cause in standard grades. Industrial facilities with chemical exposure need different furniture. Particle board works in standard office conditions—not lab spaces or manufacturing floors.

Preventative maintenance extends lifespan more than initial quality in some cases. A $600 desk with inspections each year outlasts a $1,200 desk left unchecked. Fasteners loosen. Weight distribution shifts. Small problems grow. Facilities teams that track furniture condition catch issues fast. They swap damaged panels before units fail. This approach matches how commercial buildings handle brick masonry. The structure lasts 100-plus years because crews fix mortar joints at seventy-five years. Same principle, different scale.

Conclusion

Particle board has changed modern offices completely. This material delivers both performance and sustainability. Executive desks project authority. Acoustic panels boost productivity. Particle board works across every part of today’s workspace design.

Better manufacturing methods have made a difference. So has eco-friendly sourcing. New surface treatments help too. Particle board is no longer just a cheap option. Organizations now choose it as a smart strategy.

Today’s particle board solutions offer more than low cost. They meet tough commercial standards. Plus, they support your company’s green goals.

Planning a full office redesign? Upgrading some furniture systems? Partner with manufacturers who know their stuff. Look for those who understand weight limits, finish durability, and commercial-grade building.

Ready to transform your workspace? Check your current furniture against the standards we’ve covered here. Find suppliers who can show you quality certifications and real case studies. Your employees will notice the difference. Your budget will too.