Step 1: Plan the Layout and Find the Center Line

Good planning and precise measuring are key to a great herringbone floor. I’ll show you how I get started:

Measuring the Center of the Room

Use a tape measure to find the exact midpoint between the two opposite walls.

I suggest you do not measure right against the baseboard. Measure about 6–8 inches (a hand’s width) away from the wall. This leaves room for the expansion gap and helps you avoid problems from uneven walls.

Example: For a room 150 inches wide, mark at 75 inches from each wall.

Marking and Connecting the Center Line

I use a pencil or chalk to mark the midpoints and label them “Center” on both ends so I don’t get confused.

Snap a chalk line between these marks to make a straight centerline down the length of the room. This line is your main guide and helps keep the pattern straight and even.

Deciding Pattern Direction

Choose a direction for your herringbone pattern. I usually align the pattern with the main window or the room’s longest wall. I find this uses natural light well and creates a nice flow.

In a rectangular room, running the pattern along the longest side can make the space feel bigger.

Creating Perpendicular Guidelines

Use a rafter square to mark guidelines at a 45-degree angle from your centerline. These new lines show you where to place your first planks.

Your laminate plank size might require you to add offset lines. For example, you could add a 46mm offset on each side of your centerline. I do this to make the pattern perfectly even.

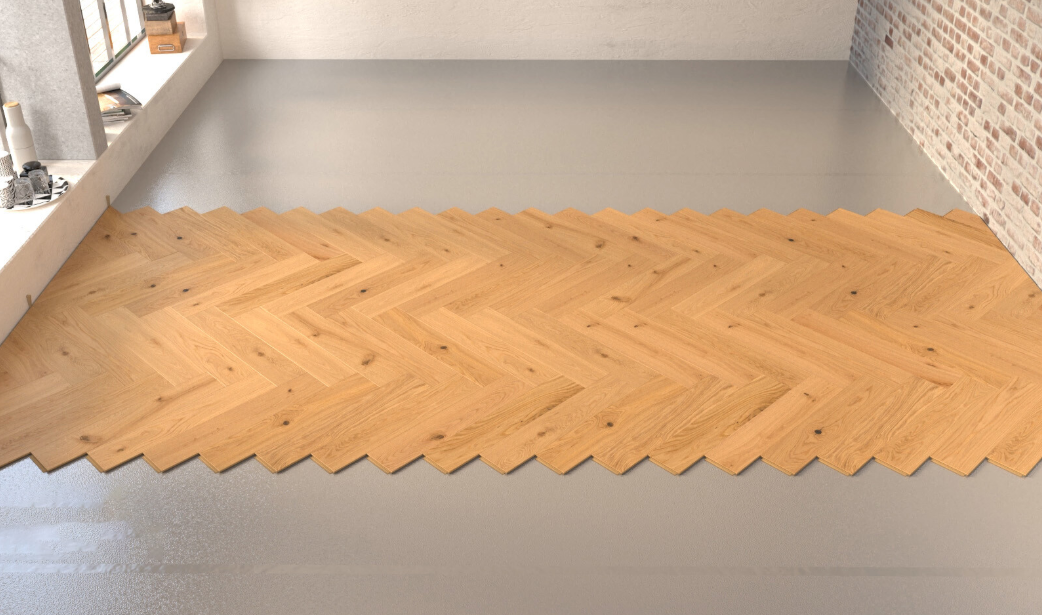

Step 2: Lay Out a Dry Run (Optional but Recommend It)

A dry run is a step I never skip. It helps you check that your herringbone pattern is straight and looks balanced before you install it for good.

How to Arrange a Dry Run for Herringbone Laminate Flooring

Lay out 10–20 planks on the subfloor without locking them together. I suggest you follow the herringbone pattern you chose. Use the centerline you marked earlier to center your layout. This gives you a balanced look.

Place your first “V” shape right on the midpoint of the room. Your chalk line is the perfect guide for this.

Take a look at the pattern: You need to make sure the A and B panels alternate. This creates that classic herringbone style.

Check for very narrow pieces next to the walls. If you see pieces that are too thin, just shift the entire layout a little bit. This little adjustment saves you from cutting odd, small pieces later.

Ensuring Consistent Angles and Accurate Alignment

Make sure every “V” shape is a 90-degree angle. The points of your pattern should line up with your guides.

If your room has an odd shape, I recommend doing a few smaller dry runs in different spots. This lets you see how the pattern flows around corners and through doorways.

I always take photos of my dry run layout. These pictures are a great reference during the final installation. You can quickly look at them to check your pattern.

Professional Insights and Dry Run Data

From my experience, a dry run for a 200–250 sq. ft. room takes about 25–40 minutes.

This step helps you find any alignment issues early. It saves you from having to re-cut or move planks later, which takes a lot of time.

Here’s a tip from my experience: About 90% of installers find they make fewer mistakes and finish faster when they do a full dry run.

If you have a big room, I suggest you divide the dry run into smaller sections. This helps keep the pattern consistent where the sections meet.

I also recommend you think about the room’s natural light and where furniture will go. You can adjust the planks to make your floor look its best.

Dry Run Checklist

- Planks are face up and not locked together.

- A and B panels alternate correctly across the layout.

- You can see your centerline and other guide lines.

- Consistent 90-degree “V” shapes across the pattern.

- You can see the gaps at the walls to plan your cuts.

- You have marked where you need to adjust for floor vents or doorways.

- You took photos of the final layout for reference.

Step 3: Build the Starting Triangles for Your Herringbone Laminate Floor

Okay, I’m ready to start laying my herringbone floor. The first thing I do is build the starting triangles, which are sometimes called chevrons or “V” shapes. From my experience, getting this step right is the most important part because it ensures the whole floor looks straight and even.

Lay Out and Align the First Triangles

Start at the center line, the one I marked in Step 1. I place the first triangle with its long side facing the wall I’m starting from.

Suggest making sure the tip of this middle triangle lines up right on the centerline. This is how I keep the pattern consistent and true across the room.

Use A-panels and B-panels one after the other:

Place B-panels (which are beveled to the left) on the left side.

Place A-panels (beveled to the right) on the right side.

Techniques for Good Assembly

Make sure each triangle locks together at a 90-degree angle. The tops should be flush, and the joints should fit tight with no edges sticking out.

A rubber hammer to tap the boards together. I always follow the instruction manual for the specific locking system of my laminate product.

Keep a 10-12mm expansion gap along the wall. I do this by placing expansion wedges. I recommend this for all laminate flooring. It gives the boards room to expand and shrink so they don’t buckle.

After every 2–3 triangles, I use a straightedge to check the alignment along the centerline. Checking now stops the pattern from getting crooked later.

Layout Examples and How Many Panels I Use

In a typical home, I find the starting row needs about 5–7 panels. This number can change based on the plank width. Most planks are 100–120mm wide and 600–700mm long.

For the layout: I suggest trying three triangles to the left and two to the right of the center. This creates a central meeting point at a 45-degree angle that I feel anchors the whole design.

To work efficiently, if I assemble an even number of triangles, I set one aside for now. If I have an odd number, I remove the two outermost triangles. I can adjust them later. This makes it easier to get a perfect fit.

Step 4: My Guide to Installing the First Full Row

I can’t stress this enough: getting the first row right is the key to a great-looking herringbone floor. This row acts as the foundation for everything that follows.

Center and Align the First Row

I always start by finding the room’s centerline. Measure the longest wall and mark its middle point. Then, I snap a chalk line down the floor to get a straight guide.

Next, lay out your A and B planks. I place the A boards on one side of the line and the B boards on the other. You need to get this right to form that classic V-shape.

Assembling and Locking the Planks Together

I begin building the first triangle where my chalk lines cross. Make sure all the V-shapes point in the same direction.

I suggest you check the row for straightness often. As you connect the boards, use a tapping block and mallet. This gives you a tight fit with no gaps. You’ll know it’s connected when the plank clicks into place.

Pay close attention to the connections. When a board is seated right, you will hear a solid “click.” You should see no gaps between the planks.

Making Sure the First Row is Centered

I recommend you double-check that your first row is centered. Is the space left at the wall smaller than one plank’s width? If so, you should adjust the whole row. This helps you avoid cutting tiny, awkward slivers of wood for the edges.

Just so you know, if you start from the center, your leftover pieces at the edges will usually be 250–400 mm long in small rooms. In larger rooms, they can be up to 600 mm.

Step 5: Continue Laying the Pattern Row by Row

Keeping the herringbone pattern consistent requires patience. You need to work in a set, repeatable way. This is the process I use after the first row to get a precise, professional look.

How I Lay A-Panels and B-Panels for the Pattern

Start each new row with A-panels. I work left to right. First, lock the short edge of an A-panel into the previous row. Then, fold it down and click the edges into place.

Once you finish the A-panels in a row, start installing the B-panels from right to left. Fold and click each one to complete the V-shape. This creates the classic herringbone zigzag with a tight, clean joint.

You should stick to this system for every row. Don’t switch the panel order or direction in the middle of the job.

Keeping the Right Expansion Gaps and Fit

I recommend using spacers or wedges along all the walls. This ensures you have a 10–12mm expansion gap. The gap is important. It lets the laminate expand and shift with humidity changes in the room.

At the end of each row, I use a straightedge and a utility knife (or saw) to cut the last panel. When you measure for this cut, double-check that you’ve included the expansion gap against the wall.

Step 6: Keep Joints Staggered and Aligned for a Perfect Herringbone Floor

To get a good-looking and long-lasting floor, I make sure every joint is staggered. The planks must stay straight and tight. Let me show you my method for getting a perfect finish on this critical step.

Maintain Herringbone Pattern Alignment

After installing a section, I always check the alignment. The plank edges and herringbone pattern must line up with my center line. A small error here can grow and ruin the look of the whole room.

Use a straight edge often. I place it on my main center line or chalk lines to check for any drift. It is much easier to make small fixes now than to deal with big problems later.

Step 7: Cutting Herringbone Laminate Planks for Walls, Corners, and Obstacles

To get a clean finish on your herringbone floor, you need to cut planks to fit at walls and around things. I’ve found this is a key step. It makes the floor look seamless and helps it last a long time.

Measuring and Marking for Precision

Measure each cut location with care: I use a tape measure and make a fine pencil mark on the plank.

For corners or odd shapes, I suggest using an angle measurer. This tool helps get the angles just right.

You must leave an expansion gap. I always recommend a 7 mm gap. Leave this space at all room edges, in transitions, and around any fixed objects. I use spacers to hold that gap open. This simple step prevents the floor from buckling later.

Before you cut, check your measurements again. Make sure your cut lines are easy to see.

Handling Obstacles and Edges

Corners: For corners, I measure the length with a tape and an angle finder. Then I mark, cut, and place the piece. I always leave my 7 mm spacer in place to double-check the gap.

Doors: You might need to remove the base molding. I lay a plank flat and slide it under the door jamb. Then, I trace the shape of the jamb onto the plank. I use a jigsaw to cut this shape out, which gives a nice, tight fit.

Pipes: Mark where the pipe is on the plank. Then, I drill a hole that is bigger than the pipe to allow for the expansion gap. I split the plank piece through the center of the hole. You can then fit the main part of the plank around the pipe. Glue the small split piece back in place behind the pipe for a finish that is hard to see.

45-Degree End Cuts: When you get to the edge of your pattern, you’ll need to finish the “V” shape. I do this by measuring and cutting a 45-degree angle. This sharp cut keeps that classic herringbone look all the way to the wall.

Step 8: Finishing the Last Row of Herringbone Flooring

To get a Professional look on the last row, I focus on careful measuring and precise cuts. Here is the step-by-step process I follow:

Measure and Plan for the Final Row

Start by measuring the gap width between the installed row and the wall. I do this in several spots. Based on my experience, you must leave a 10–12mm expansion gap. Don’t skip this part.

I recommend using spacers or expansion wedges every meter. This ensures the expansion gap stays even.

Trim and Fit Your Planks

Mark each plank: I lay the plank loosely next to the gap. Then I use a pencil to mark where I need to cut it. I double-check that all A and B panels are in the right position to keep the herringbone pattern correct.

Cut the planks to size. I use a jigsaw or a laminate cutter. For example, in a 2.5m wide room, I usually have to trim every plank in the final row. This can leave me with narrow strips, sometimes only 8–12cm wide.

Test-fit every piece. I always make sure the plank fits before I install it. Each piece should lock in without pressing against the wall. I use a straightedge to check for proper alignment and height.

Install the Final Row

To fit a plank, I angle its long side up to about 30°. Then, I pull it toward myself to lock it into the tongue-and-groove.

Use a rubber mallet to tap the short ends of the planks together. This gives me a tight, flush seam.

For the smallest pieces, I suggest using a small dab of laminate glue. The locking system might not hold tiny triangles, and glue stops them from shifting.

For example, in a 4m x 3m room, I often need to fit 6–10 separate pieces for the last row. This is common when walls are not straight.

Step 9: Install Flooring in Doorways and Thresholds: Expansion Gap & Trim Guide

When I install herringbone laminate in doorways and at thresholds, I focus on two things. First, the look needs to be seamless. Second, the floor must have room to move. Here’s the workflow I use every time:

Essential Steps for Fitting Herringbone Laminate in Doorways

Leave a 10mm Expansion Gap:

Seave a 10mm gap between the new laminate and any old flooring. This gap stops the floor from buckling when it expands or contracts. To get the distance right, I use a spacer or a small wooden wedge.

Undercut Doorjambs for a Professional Finish:

Before I fit planks in a doorway, I first undercut the doorframe. The cut must match the thickness of the laminate. I use a scrap plank as a guide. I place it flat against the jamb to mark my cutting line. Then, I use a handsaw or a multi-tool to make the cut. This lets the new plank slide right underneath.

My Tip: With this method, you don’t have to cut the laminate to fit around the frame. You get a much tighter and cleaner edge.

Cut Planks for the Doorway:

Measure the doorway’s width and subtract 10mm for the expansion gap. This means 5mm on each side. I use a try square and pencil to get accurate marks. I always suggest cutting the plank with the décor side down for the cleanest edge.

Install Planks Halfway Under the Door:

For the best look, I recommend laying the floor so it ends halfway under the closed door. This makes the transition between rooms look sharp. It also hides the expansion gap under the door.

Adding Threshold Bars & Finishing Touches

Fit the Threshold Bar or Transition Trim:

After I lock the planks in, I add a threshold bar or a matching trim. I make sure it’s one the manufacturer recommends. This bar covers the expansion gap. It also creates a strong and clean transition. I find this works very well between two different floor types or at an exterior door.

For a standard UK doorway (about 762mm wide), my plank cut is 742mm to allow for the gap.

Finalize the Fit:

Slide each cut plank into place under the jamb. I always double-check that my threshold bar sits level and lines up with both floors.

Data Point: The expansion gap needs to be 10mm.

For a high-end look, I use a threshold bar that is thick enough to sit flush with both floors.