Custom Printed Vinyl Flooring: Design, Durability & OEM Solutions for Commercial Spaces

Custom-printed vinyl flooring is a game-changer for commercial spaces. I believe it offers incredible design freedom and branding opportunities. You can print any design on a strong vinyl surface. This includes company logos, bold graphics, and realistic patterns like wood grain or Italian tiles. You can even use photographs. Because it’s so flexible, I recommend it for retail, events, offices, museums, trade shows, and hotels.

What I Like About Its Features and Options

You can create a personal brand statement: For instance, a sports store could make its floor look like a swimming pool. An estate agency could display a city map. I’ve even seen electronics stores put complex motherboard designs right on the floor.

It comes in versatile sizes: Manufacturers offer large products up to 2.9 meters wide. This is great for creating seamless floors. You can get it in sheets or luxury vinyl tiles (LVT).

Types of Custom Printed Vinyl Flooring

If you’re a commercial buyer, you have several types of custom printed vinyl flooring to choose from. I suggest picking one based on your space, how durable you need it to be, and your branding goals.

Rolled Vinyl Flooring

Rolled vinyl flooring comes in large, seamless sheets. Standard sizes go up to 10’x10′. I find this format is great for a smooth, unbroken look. It’s a popular choice for large spaces like exhibition halls, trade show booths, and big retail stores. The printing uses CMYK dye sublimation or UV technology. This method creates bold, vivid graphics that make a strong brand statement.

Construction: It’s made of 100% PET Polyester with a vinyl backing. This gives it both strength and flexibility.

Performance: It has a 2.0 mil pile thickness. In my experience, this adds extra durability in busy areas.

Lead time & pricing: Surface-printed rolls are ready in 10–12 business days, starting at $13/sq ft. Reverse-printed rolls take 15–20 business days and start from $17/sq ft.

Printed Vinyl Tiles and Decals

If you need more creative freedom, I recommend looking at modular tiles and decals. You can get them in over ten standard and custom formats. This allows you to create unique layouts or mark special zones in your commercial space.

Construction: These are made from Polymeric PVC with a vinyl backing. You can get them in a matte finish.

Key features: They come with certified slip-resistant coatings. This improves safety in public areas and workplaces.

Adhesive: They use a strong but removable adhesive. This means you can install and adjust them quickly, without leaving any sticky mess behind.

Printing Methods: Surface vs. Reverse Printed

Surface Printing: The graphic design is printed right on the top layer of the vinyl. I like this method for its bright colors and quick turnaround. It is perfect for events, temporary branding, or anywhere you need a big visual impact. The downside is that it’s not the most durable option. I recommend it for short-term use where speed is important.

Reverse Printing: With reverse printing, the image sits underneath a tough, protective wear layer. This greatly improves durability. From my experience, it’s the best choice for busy retail stores, trade show walkways, or office spaces that need long-term branding. The cost and production time are a bit higher, but you get much better longevity and wear resistance in return.

Comparison Table: Typical Product Features

| Type | Lead Time | Price (from) | Durability | Typical Use |

|---|---|---|---|---|

| Surface-Printed Roll | 10–12 business days | $13/sq ft | Moderate (events) | Fast branding, short-term flooring |

| Reverse-Printed Roll | 15–20 business days | $17/sq ft | High (long-term) | Retail, trade shows, offices |

| Modular Tiles/Decals | 10+ sizes, fast | Custom | Medium to high | Retail, events, wayfinding, branding |

Highlighted Features and Use Cases

Slip Resistance: You can get certified anti-slip coatings on all commercial options.

Installation Flexibility: You can install most of these products with double-sided tape or pressure-sensitive adhesives. This makes it easy to move them around or take them up without hurting the floor underneath.

Eco-Friendly Options: Many products use UV, latex, or eco-solvent coatings. These have lower VOC emissions and are safer for the environment.

You have several great options: rolled sheets, modular tiles, and graphic decals. I believe that with these choices, any commercial buyer can find the right balance of durability and visual appeal for their custom printed vinyl flooring.

What You Can Do with Custom-Printed Vinyl Flooring

Custom printed vinyl flooring offers many choices for your brand and design needs. I find it works well for many business uses.

Flexible Sizing and Shaping

You can get vinyl flooring made in any size to fit your space.

I’ve seen rolls come in widths up to 3100mm (over 10 feet). You can order any length you need.

You can split designs into sections that join together perfectly on-site.

If you have a tricky or unique floor plan, I suggest using contour cutting for a perfect fit.

Advanced Printing and Visual Effects

The new digital printing creates very clear, photo-quality images.

You can print almost anything. I’ve seen abstract art, natural textures, company logos, and even large photos.

There are hundreds of templates available. You can change their colors to match your brand or specific Pantone shades.

You can also create a brand-new design from scratch based on your project goals.

Print Methods and Durability Options

Surface-Printed Vinyl: This option gives you bright colors and accurate PMS matching. It comes in large rolls up to 10 feet wide. I like that it’s fast, with a 10–12 business day turnaround. Prices start at $13 per square foot. I recommend this for trade shows or short-term events because of its standard durability.

Reverse-Printed Vinyl: Here, the print is under a strong protective layer. This is great for busy places like exhibit halls or store entrances. It takes longer to make (15–20 business days) and costs more, from $17 per square foot. I believe it’s the best choice when you need something that lasts a long time.

Finish, Texture, and Safety

I suggest choosing a surface that is tough and resists scratches.

You can also get non-slip textures. These help you meet safety rules for business spaces.

Easy Installation and Reusability

The flooring comes in either rolled sections or easy-to-handle tiles.

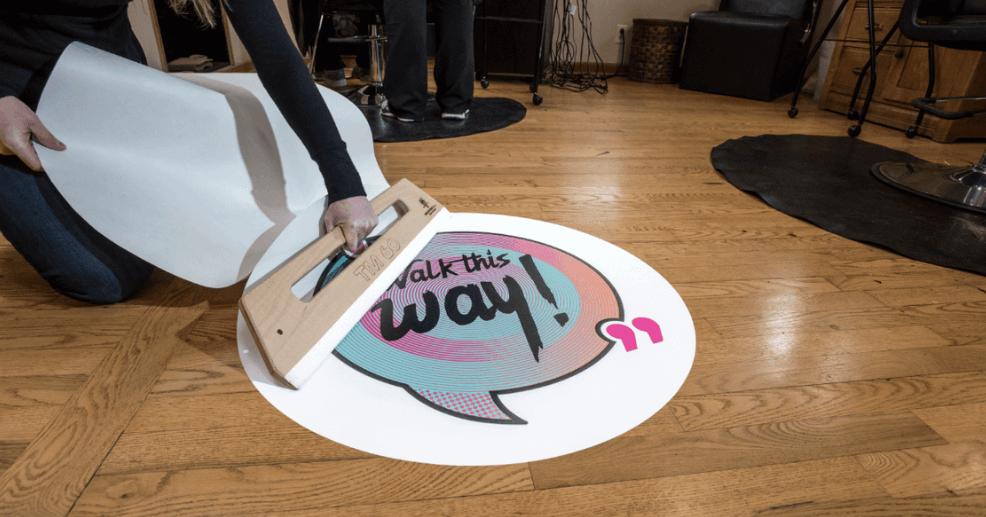

I find many of these products are easy to remove and use again. This is perfect for trade shows or events that require quick setup and tear-down.

Versatile Color and Pattern Choices

You have many design choices. You can pick simple colors, detailed brand graphics, or even realistic looks like grass or water.

Based on my experience, custom color matching ensures your flooring perfectly matches your brand.

Cost and Minimum Orders

Custom flooring starts at $13–$17 per square foot. The price depends on the printing style and how durable you need it to be.

Minimum orders usually start around $1,000. I think this makes it a good option for both small and large projects.

Typical Commercial Applications and Examples

I’ve seen it used in many places: trade show booths, pop-up shops, stores, museums, offices, and at promotional events.

People use it to create brand-focused spaces. Matching company colors and graphics makes a big impact.

I believe these custom options let you control every detail of your vinyl flooring. You get a great look and flooring that performs well in busy areas.

Buying Custom-Printed Vinyl Flooring: A B2B Guide to Design, Options & Sourcing

If you’re buying custom printed vinyl flooring for a commercial project, my experience shows that a clear process is key. Here is the approach I recommend. I will focus on important terms like the “buying process,” “OEM vinyl flooring,” and “Commercial Vinyl Flooring procurement.”

1. Choosing and Vetting Your Supplier

First, I suggest you list out exactly what you need. Think about design freedom, durability, slip resistance, the finish, size, and format.

Find suppliers who offer digital print technologies, flexible sizing, and strong, commercial-grade vinyl.

I recommend asking if they offer no minimum order quantities. This is very important if you need a prototype or have a specific custom request.

In my opinion, you should favor suppliers with experience in wide-format prints up to 10 feet (2.9–3 meters). This gives you a cleaner look with fewer seams.

2. Getting the Design, Samples, and Proofs Right

Ask for physical samples and digital proofs of your design. The best suppliers use Pantone color books to get the colors just right.

For special projects, you should confirm if they offer direct-to-vinyl or mirrored second-surface printing.

I always advise clients to approve production samples before placing a full order. This ensures the final product is exactly what you envisioned.

3. Quotes, Timelines, and Budgeting

Get full quotes that show the price per square foot. The quote should also list minimums, which are often around $1,000, and production times. For example, rolls might take 10–12 days for surface printing or 15–20 days for reverse-printing.

On-demand digital production is a great benefit. It means you hold less inventory, get a quick turnaround, and logistics are much simpler.

Remember to budget for installation costs. Professional installers often custom-cut the flooring on-site, which I believe gives a perfect fit.

4. Placing the Order and Starting Production

You can send your finished art files to the supplier. Or, you can choose from the patterns and templates they provide.

You must approve the final proofs before the main production run starts.

For commercial rolls, I suggest you ask for the widest practical width, up to 10 feet. This helps reduce seams and makes installation faster.

5. Managing Delivery and Installation

You should schedule shipping to match your construction or event timeline.

The installation process involves unrolling the vinyl, trimming it, and fixing it with tape or adhesives. This is common for trade shows and large commercial buildings.

I recommend asking your supplier for a list of professional installers they trust. This helps ensure you get the best result.

6. Support, Warranty, and Care

You should carefully review the supplier’s warranty coverage. Check what it covers for wear, graphic quality, and any installation defects.

Get clear instructions on care and cleaning. I know from experience that proper maintenance makes the floor last longer and keeps it looking new.

I believe good customer service should be available to you through every stage of your project.

If you follow this process, I am confident your OEM custom-printed vinyl flooring will meet your branding goals and practical needs. You’ll also have reliable support at every stage. Today’s digital printing provides fast, flexible, and cost-effective flooring for any commercial space.