MDF Panel Manufacturers in Brazil And Latin America: A Comparative Overview

| Company | Country / Region | Annual MDF Capacity (m³) | Technology & Equipment | Density Range (kg/m³) | Key Product Focus | Sustainability & Certifications | Market Presence |

|---|---|---|---|---|---|---|---|

| Baier | China | ≈600,000 | Continuous hot-press lines, automated sanding & trimming, precision refining | 650–850 | MDF, MR MDF, HDF, melamine-coated panels | CARB2, E1, FSC, ISO 14001; biomass power & waste heat recycling | Asia-Pacific, Middle East, Oceania |

| Arauco | Brazil / Latin America | ≈815,000 (Brazil) / 2.9 million (LATAM) | Siempelkamp lines, Wemhöner laminating systems | 650–850 | MDF, PB, Plywood, melamine & HDF | Sustainable forestry (1M ha managed forest) | Latin America, Global export |

| Guararapes | Brazil (Caçador) | ≈1.14 million | Siempelkamp ContiRoll Gen 9, EcoResinator, Valmet Defibrator EVO | 700–850 | MDF, HDF, Plywood | Closed-circuit water reuse, rainwater collection, low-chemical resin | Brazil, Latin America export |

| Berneck | Brazil (Lages, Curitibanos) | ≈1.2 million | Siempelkamp ContiRoll Gen 9, Dieffenbacher dryers | 700–850 | MDF, HDF, MDP, laminated panels | Renewable raw materials, efficiency-focused upgrades | Brazil, Latin America export |

| Asperbras (GreenPlac) | Brazil (Mato Grosso do Sul) | 300,000 → 460,000 (planned) | Fully automated Siempelkamp line | 650–850 | Melamine-faced MDF | 100% self-produced resin & biomass energy; FSC forests | Brazil domestic |

| Fibraplac | Brazil | ≈550,000 | German Siempelkamp lines, advanced coating systems | 700–850 | Laminated MDF | Sustainable sourcing; ongoing process innovation | Brazil, international |

| Eucatex | Brazil (Salto) | ≈275,000 | Dieffenbacher MDF/HDF line | 850–880 (HDF) | Thin HDF, MDF | FSC forestry, ISO-compliant; reforestation (13M seedlings/year) | Brazil domestic |

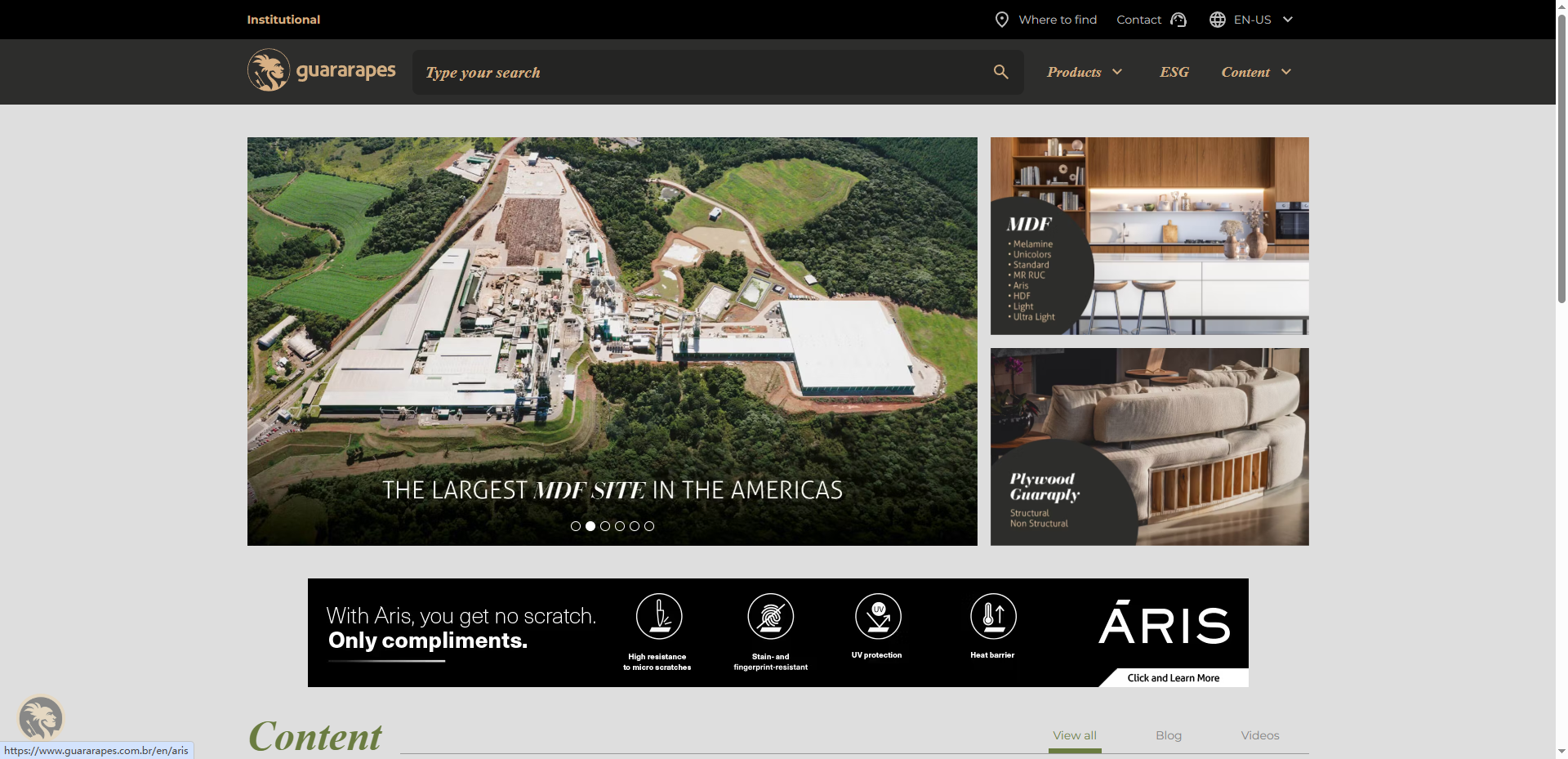

Guararapes: A Top MDF Panel Maker in Brazil

Facility and Production Capacity

Caçador Industrial Complex:

The site covers 243,568 sqm and has three MDF production lines.

I find their water system very smart. It has special drainage and three lakes that collect rainwater. These lakes hold a combined 38,132 cbm, which greatly helps in saving water.

Advanced Technology:

The factory uses a Siempelkamp ContiRoll® Generation 9 press (9′ x 48.7m). This machine can produce 1,500 m³ of MDF each day.

They also have EcoResinator glue blending and Valmet Defibrator EVO systems. In my opinion, this is great because these systems improve fiber quality and use less energy. This lowers their impact on the environment.

Digital scanners constantly check the surface quality. I suggest this is a good way to make sure every product meets a high standard.

Sustainability and What They Do for the Environment

Water Reuse:

They use closed-circuit evaporators and rainwater lakes. This setup recycles water well and creates almost no wastewater.

Green Production:

The EcoResinator technology reduces the need for chemicals. They also reuse condensate from wastewater treatment in the production process.

Economic and Social Benefits

Job Creation:

The most recent plant expansion created around 280 direct jobs and 650 indirect jobs.

While building the plant, over 700 workers had jobs. I believe this provided a real economic boost to the local region.

Products and Market Presence

Products:

The company makes a variety of MDF and plywood panels. These are designed for use in construction and furniture.

Export Presence:

They supply products to the Brazilian market and export to many countries across Latin America.

Growth and Industry Position

Guararapes began in 1984 as a small sawmill. Now, I see them as a model for sustainable MDF production in Latin America. Here are some of their key achievements:

– They made smart investments in their facilities and expanded into new markets.

– They launched their first MDF plant in 2009 and have been upgrading capacity ever since.

– They reached a top spot with a production ability of 1.14 million cbm.

Key Sustainability Features I Like

A closed-circuit evaporator system that reuses condensate

Rainwater collection lakes with a 38,132 cbm capacity

EcoResinator glue blending that uses few chemicals

Digital inspection to ensure high product quality

Baier Floor: Leading MDF Panel Manufacturer in China and Asia-Pacific

Production Capacity and Core Operations in China

High-Volume Manufacturing: Baier operates one of the largest MDF production bases in East China. Its main facility, located in Wuhan, Hubei Province, has an annual MDF output of approximately 600,000 m³, supported by advanced continuous press technology. The plant maintains multiple production lines for both standard and moisture-resistant MDF panels, ensuring a flexible supply across the Asia-Pacific region.

Regional Presence:

Through a combination of domestic manufacturing and export distribution networks, Baier now supplies MDF to more than 30 countries, including Australia, Southeast Asia, and the Middle East. This network enables consistent delivery and short lead times for high-volume customers.

Product Range:

Baier’s MDF portfolio includes standard, moisture-resistant (MR), and high-density (HDF) grades, as well as melamine-coated and veneered panels. Product thicknesses range from 2 mm to 25 mm, with densities between 650 and 850 kg/m³, covering requirements for furniture, flooring substrates, cabinetry, and decorative applications.

Technology, Investment, and Expansion

Advanced Production Lines:

Baier’s MDF manufacturing lines are equipped with continuous hot-press systems, precision fiber refiners, and automated sanding and trimming machines. These systems improve board uniformity, minimize waste, and ensure stable mechanical performance—particularly important for architectural and furniture applications.

Ongoing Investments: In recent years, Baier has continued to modernize its production and environmental facilities, investing over US$50 million in high-efficiency fiber preparation, resin blending, and emission control equipment. This ensures compliance with CARB2, E1, and FSC requirements while maintaining high output consistency.

Expansion into Laminated Products:

To meet the global shift toward value-added MDF, Baier has increased its laminating and surface finishing capacity by more than 40% since 2022. The company’s decorative panel line can produce up to 300 melamine-coated panels per hour, supporting both OEM and branded exports.

Sustainable Forestry and Raw Material Chain

Integrated Resource Management:

Baier sources its wood fiber from certified, sustainably managed plantations within China’s Yangtze River Delta region. The company maintains long-term partnerships with FSC-certified forestry suppliers, ensuring a traceable and eco-responsible material chain from plantation to final board.

Environmental Benchmark: All MDF production meets E0–E1 formaldehyde emission limits and aligns with ISO 14001 environmental management standards. Waste heat and biomass are recycled for power generation, reducing total CO₂ emissions by over 15% per cubic meter of production compared with conventional plants.

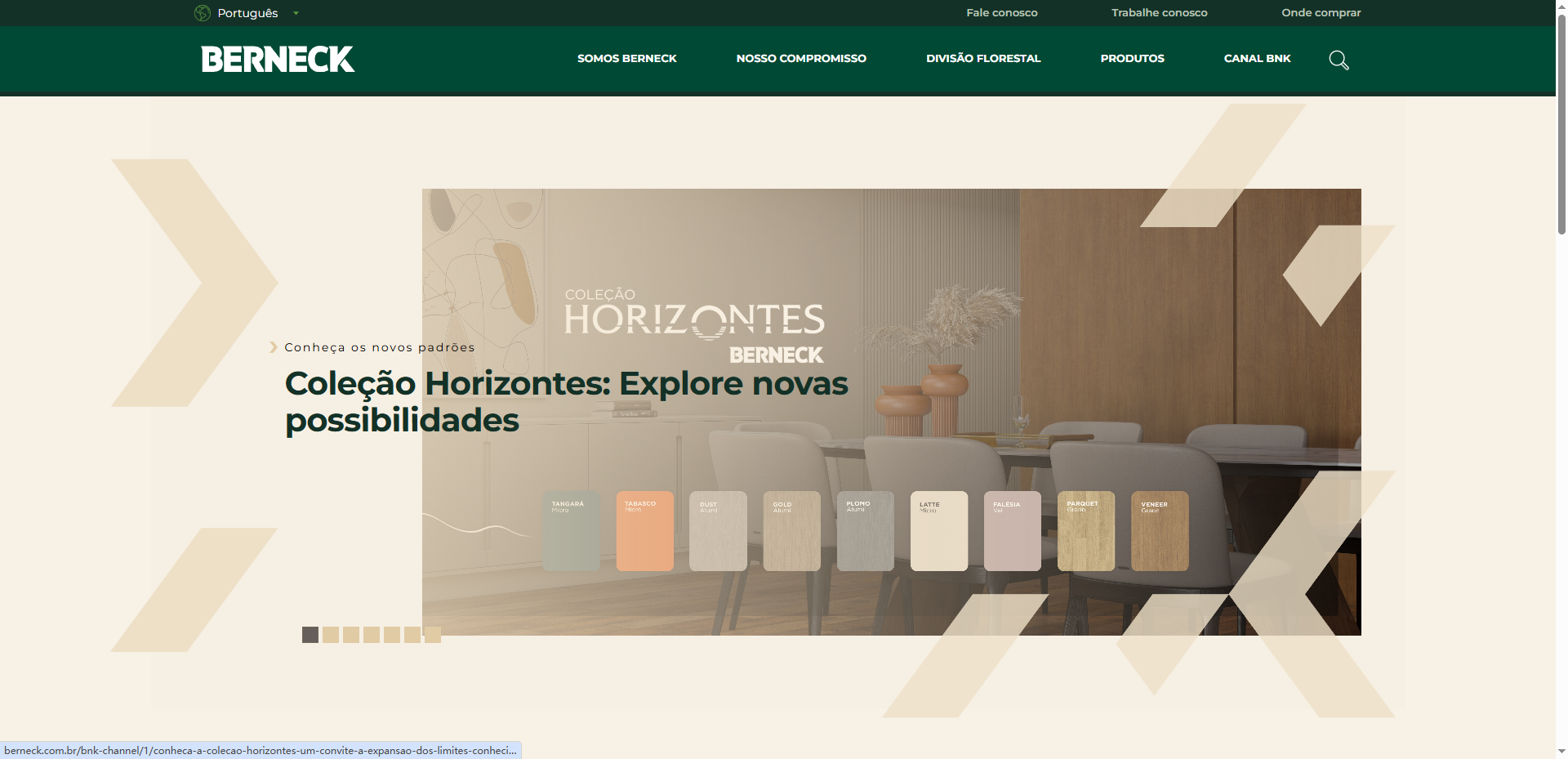

Berneck: A Leading Panel Producer in Brazil

Production Capacity and Manufacturing Sites

Lages Mill: The modern Lages Mill in Santa Catarina is a great example of their scale. From what I’ve seen, it produces 1,665 m³ of MDF each day. This adds over 600,000 m³ to Berneck’s output every year.

Curitibanos Facility: At their Curitibanos factory, they upgraded to the world’s largest drum dryer from Dieffenbacher. I think this was a smart move. It is increasing their particleboard (MDP) production from 1,200 m³ to 2,700 m³ per day.

Overall Capacity: With all factories combined, Berneck produces more than 1,200,000 m³ of panels a year. This production level easily places them among the largest panel producers in Latin America.

Scale of Operations: They have a large team of about 1,600 employees. Their three production sites cover a built area of more than 170,000 m².

Technology and Innovation

Advanced Machinery: I’m impressed that Berneck uses advanced machines. Their new Lages line, for example, uses Siempelkamp ContiRoll Generation 9 technology. This system has a very flexible press that helps them work efficiently and make high-quality products.

Investment in Coating: In 2020, they added a Wemhöner short-cycle press in Curitibanos. I feel this was a direct response to strong market demand, and it helped them increase the production of laminated MDF and HDF panels.

Engineering Partnerships: The company works with top technology suppliers like Dieffenbacher and Inserco. From my experience, partnerships like these are key to creating new and better processes.

Market Influence and Product Applications

Distribution and Exports: Berneck is Brazil’s biggest exporter of wood-based panels. They supply panels for furniture, construction, and architecture. I’ve noticed they serve markets both inside Brazil and in other countries.

Sector Leadership: Their continued growth has made Brazil’s market stronger. The country now has an installed MDF/HDF capacity of over 8 million m³ per year. This is the highest capacity in all of South America.

Product Range: I recommend paying attention to their product focus. They make panels that are useful for many things in the construction and furniture industries. They also use renewable raw materials, which is important.

Impact and Industry Position

Berneck keeps investing in new technology and upgrades. This has helped them become one of the top six wood panel companies in Latin America.

Based on my experience, people know their panels for their quality and new ideas. They are a big reason why Brazil is growing as a top global producer of MDF and HDF.

Asperbras (GreenPlac): Integrated and Sustainable MDF Panel Production in Brazil

Production Facilities and Capacity

Annual MDF Output: They make 300,000 cubic meters of MDF a year. They have plans to increase this to 460,000 m³ with a second production line.

Industrial Complex: The company’s complex covers 510,000 m². It includes the MDF production lines plus their own resin and Formaldehyde plants.

Vertical Integration: I like how they operate a 17,000-hectare eucalyptus farm with FSC certification. This provides a steady and sustainable wood source.

Laminating Line: They invested to increase laminating capacity by over 70,000 m³ per year.

Resin & Formaldehyde: Their own resin plant makes 160 tons a day. Formaldehyde production is at 3,000 tons per year and is in a testing phase.

Sustainability and Innovation

Self-sufficiency: I recommend their approach. They make 100% of the resin and formaldehyde used in their MDF. This ensures good quality control and a stable material supply.

Energy Efficiency: They use biomass energy from wood waste. This is impressive because it reduces their need for outside energy.

Eco-Certification: All their forest wood is FSC-certified. This shows a real focus on responsible forestry, which I admire.

Automation: The factory is completely automated using German Siempelkamp technology. This improves efficiency and keeps product quality consistent.

Product Range, Market, and Expansion

Core Products: Their main products are melamine-faced MDF panels for the furniture market. They offer over 22 coatings. I find their focus on cut-to-size jobs to be a great service.

Distribution: The company crew very fast. They built a network of 175 sales points across Brazil in their first year. This shows the market accepted their products well.

Expansion Plans: A second MDF line is planned. This will raise their total production capacity as their forests mature. I suggest watching their next moves, as they also plan to expand into other processes.

Financial Investment and Growth Strategy

Initial Investment: They began with an R$500 million (US$160 million) investment. I think this made GreenPlac one of the most modern MDF production sites in Latin America.

Business Focus: Their goal is to meet the demand from Brazil’s growing middle class. The urban housing and furniture markets are also getting bigger.

Recognition: FIEMS has given them awards. This recognizes their positive impact on the economy of Mato Grosso do Sul.

Key Highlights

They control the entire supply chain, from the eucalyptus forest to the finished MDF panel.

I like that they produce their own resin and formaldehyde. This helps ensure quality and keeps costs down.

They use renewable energy from their own biomass power plant.

They have a creative product lineup and offer customization for the furniture industry.

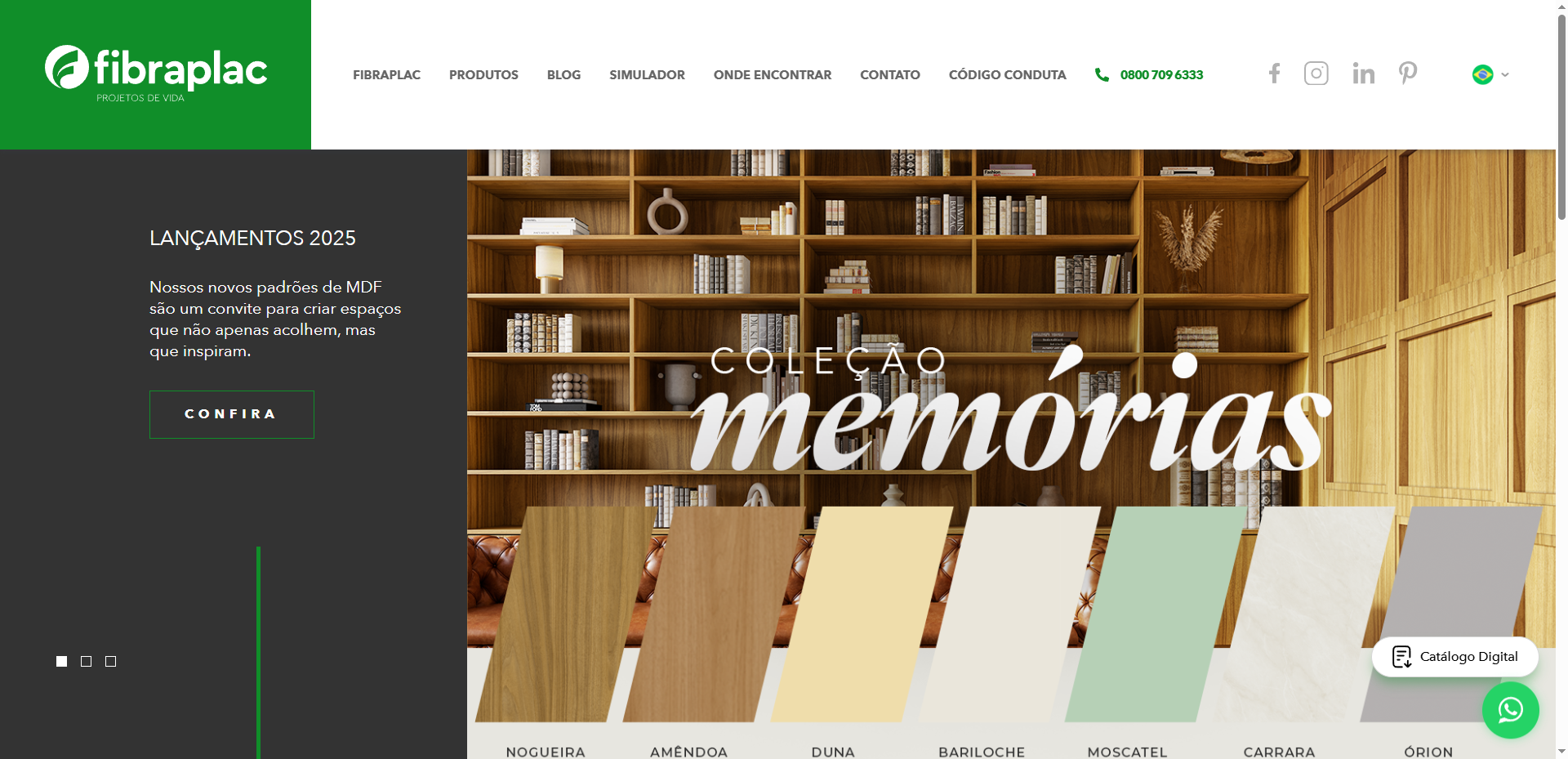

Let’s Look at Fibraplac: A Tech Leader in MDF Panels

Production Capacity and Advanced Technology

Annual Output: Fibraplac produces about 550,000 m³ of MDF each year. In my opinion, this volume makes them a top producer in Brazil. That is a significant part of the country’s total panel capacity of over 8 million m³ per year.

Production Lines: The factory has two main MDF production lines. Each line makes around 250,000 m³ per year. Through smart investments, their total output now exceeds 500,000 m³.

Automation and Machinery: I think it’s notable that the company uses automated production lines from Germany’s Siempelkamp. They keep upgrading with new presses and advanced coating tech. Based on my experience, this focus supports Fibraplac’s reputation as a tech leader in Brazil.

Product Range and Markets

Laminated MDF Panels: I see that Fibraplac concentrates on laminated MDF boards. I recommend these for furniture manufacturing, construction, and interior design projects.

Raw Materials: Their MDF panels use eucalyptus and pinus. These materials come from Brazilian forests.

Domestic and Export Presence: I believe their focus on quality is key. It helps them serve clients all over Brazil. It also opens doors to international markets.

Key Competitive Strengths

Commitment to Innovation: The company always invests in technology and process upgrades. From my view, this is to get higher efficiency and better products.

Employee Training: I suggest paying attention to their employee training. They invest in their team to build expertise. This supports Fibraplac’s high standards.

Industry Recognition: The company is young; commercial production started in 2004. Even so, it is now a major player in the Latin American MDF sector. I have seen it ranked with big names like Duratex/Dexco, Guararapes, Berneck, and Arauco.

Industrial Growth and Resilience

Isdra Group Backing: I think being part of the Isdra Group helps. It has allowed Fibraplac to handle economic challenges by investing in expansion and modern manufacturing.

Expansion Milestones: I recommend looking at their growth. A major expansion in 2006 doubled its production lines. More growth in the coating line in 2008 raised capacity to today’s levels.

Quality Reference: Fibraplac is a global benchmark for laminated MDF quality. This makes the company a leader in local and export markets.

Eucatex: A Key MDF & HDF Panel Maker in Brazil

What I See in Their Facility and Production

Single MDF/HDF Line: Eucatex uses one Dieffenbacher production line. This line has a yearly capacity of 275,000 cubic meters. This number represents about 3.3% of Brazil’s total MDF production, which tops 8 million m³ a year.

Thin HDF Focus: I find it interesting that their Salto facility was the first in Brazil built for thin fibreboard production. It makes HDF panels with a density of 850-880kg/m³. this is much higher than the standard 750kg/m³ for MDF.

Top-Notch Surface: This specialized process results in a superior surface finish. I believe this makes their thin HDF products notable for their quality.

Market Strategy and Growth

Focus on Brazil: Almost all of their products are for the Brazilian market. A small 10% portion is exported.

High Demand: I was impressed to learn the plant was expected to sell out its capacity just six months after it opened. This shows a very strong local need for their thin, high-density boards.

Smart Investments: In November 2022, Eucatex started to grow its MDF production. They invested in new technologies and equipment to improve output and efficiency.

My Thoughts on Their Forestry and Sustainability

Self-Sufficient Wood Supply: I like their sustainable approach. Eucatex plants about 6,000 hectares of forest each year. They also produce 13 million seedlings every year to secure their material supply.

Diverse Products: The company is also one of two top producers of wet process hardboard in Brazil. I suggest this is a good move, as it gives them a wider product range than just MDF and HDF.

Strategic Plans and Industry Standing

Future Projects: I see that Eucatex has explored plans for a bigger MDF plant. It would have a 500,000m³/year capacity. They have also thought about expanding into Mato Grosso do Sul. I recommend watching their development of wood complexes in southern and northern Brazil.

Market Opportunity: Eucatex is targeting Brazil’s growing panel market. This segment has seen more than 30% average growth. MDF volumes increased by 50% and thin MDF by 25% in recovery periods.

My Key Takeaways

First Brazilian facility creating thin, high-density HDF.

The company serves the domestic market with few exports.

I like their ongoing investments in MDF efficiency and tech.

They have a solid focus on managing forests for sustainable wood.

They are looking at large-scale expansion to meet market growth.