Walk into any construction site or furniture workshop. You’ll spot sheets of this engineered wood product stacked everywhere. Yet many people still don’t know what Oriented Strand Board is. They wonder why it’s become the go-to material for builders, designers, and DIY enthusiasts.

This panel has changed how we build homes and create interiors. It offers strength and affordability. Plus, it has aesthetic potential that traditional plywood can’t always match.

Planning a major renovation? Exploring sustainable building materials? Or maybe you’re curious about that distinctive wafer-like surface you keep seeing in design magazines. Understanding OSB’s unique properties helps. Learn its diverse uses and practical limits. This knowledge leads to smarter decisions for your next project.

OSB works for structural sheathing. It also creates trendy accent walls. This guide breaks down everything you need to know about working with this material.

What Is OSB? Definition and Core Characteristics

Oriented Strand Board (OSB) is engineered wood made from compressed layers of wood strands. These strands bond together with waterproof resin adhesives. Armin Elmendorf invented this material in California in 1963. OSB changed construction forever. It uses the entire tree—crooked, knotty, and deformed timber included. Traditional lumber production throws these parts away.

The Anatomy of OSB

The details make OSB special. Each wood strand measures 8–15 cm long. Manufacturers cut them from debarked logs. Individual pieces run about 100 mm along the grain and 5–50 mm across it. These strands mix with heat-cured synthetic resin binders. Then they’re arranged into three layers. The outer strands align in the panel’s long direction. This creates that wafer-like pattern you see on every OSB panel.

Here’s what makes it strong: the oriented layers spread weight across the entire surface. No internal gaps. No voids. Just continuous wood fiber resisting deflection, warping, and distortion.

Physical Characteristics That Matter

OSB weighs between 600–680 kg/m³. A standard 2400 × 1200 × 12 mm panel weighs about 20 kg. Light enough to move around. Heavy enough to feel solid.

The surface has its own look. That rough, textured appearance ranges from light straw to medium brown. Wood species, resin type, and pressing conditions affect the color. Plywood has varying grain patterns. OSB gives you uniform strength throughout. You won’t find knotholes or weak spots beneath the surface.

OSB resists water thanks to its waterproof resin binders. But it needs extra membranes for complete water protection. Don’t skip the protective treatment on outdoor projects. That’s asking for problems.

OSB Types and Classification System

The construction industry uses clear performance grades. Oriented Strand Board comes in specific categories. Each type fits different conditions and load needs. Know these classifications. This knowledge protects you from expensive mistakes and structural problems.

European Standards: OSB/1 Through OSB/4

The EN 300:2006 standard sets four types. Load capacity and moisture resistance separate them:

OSB/1 (GP-REG) works for general use, non-load-bearing jobs. Furniture backing, interior panels, and decorative pieces use this grade. It only works in dry conditions. Humidity destroys it.

OSB/2 (LB-REG) handles load-bearing work. But it still needs dry spaces. Interior structural framing uses this grade. Pick it where moisture stays under control.

OSB/3 (LB-MR) runs most construction sites. This load-bearing panel handles humid conditions. It tolerates up to 85% relative humidity for long periods. Most builders pick OSB/3 by default. It takes real-world weather during construction. Plus, it keeps structural strength afterward.

OSB/4 (HLB-MR) gives heavy-duty performance. Tough structural jobs need this grade. High-load floors, critical roof assemblies, and engineered building systems require it. You’ll pay $18-25 per 4×8 sheet (7/16″ thickness). That’s still 10% less than similar premium plywood.

North American Performance Categories

APA standards (PS 2 / PRP-108) work differently. They sort by end-use instead of abstract grades:

Rated Sheathing panels work for walls, roofs, and subfloors. Span ratings like “24/16” show maximum joist spacing. 24 inches for roofs, 16 inches for floors. Prices run $10-15 per sheet. Great value for big structural projects.

Sturd-I-Floor panels cut out separate underlayment. These sanded, tongue-and-groove panels fight puncture damage better than standard sheathing. Expect to pay $15-22 per sheet for this premium floor option.

Rated Siding panels take on exterior exposure directly. Enhanced bond strength and weather resistance get built into production.

Structural 1 designation shows panels meeting strict requirements. Panel thickness must be ≥23/32 inches. Bending strength needs ≥34 psi parallel to grain. Internal bond requires ≥85 psi. Hurricane zones and high-wind areas need this spec. Florida Building Code requires Structural 1 panels for wind loads over 140 mph.

The Cost-Performance Reality

OSB/3 gives the best value. You’ll save 15-25% compared to equal sheathing plywood. You also get better dimensional stability. That 25% lower cost-to-strength ratio creates big differences on large jobs. A typical 2,000-square-foot home needs 60-80 sheets of sheathing. Those savings pile up quick—$200-400 in material costs alone.

Construction Applications: Structural Uses

Oriented Strand Board controls three key building areas: roofs, walls, and floors. Each spot needs different performance features. Builders switched to OSB for good reasons. It stays stable and spreads weight evenly across the whole panel.

Roof Sheathing: The Primary Defense Layer

Roof decking handles snow loads, wind uplift, and fastener forces all at once. OSB panels for roofs use 7/16″ thickness for 24-inch framing. The strand structure fights racking better than solid lumber. No weak grain patterns. No knotholes causing breaks.

Installation speed counts here. A skilled crew covers a 2,000-square-foot roof in 6-8 hours with OSB. The panels have uniform thickness. This means no shimming needed. They stay stable and prevent wavy roof lines that hit lower-grade materials. Space the edges right—1/8 inch between panel edges, 1/4 inch at end joints. Temperature changes make the panels expand. Skip these gaps and you’ll hear buckling in your first season.

Wall Sheathing: Lateral Load Resistance

Structural wall sheathing turns stud framing into solid units. OSB/3 panels for walls give you the shear strength that keeps buildings upright during wind and earthquakes. The cross-layered strands create equal strength in both directions. This matters big time since forces can hit from any angle.

Nonresidential construction proves this point. The institutional sector expects 3.8% spending growth in 2026. Healthcare facilities lead at 4.3% expansion. Education buildings grow 3.2%. These buildings need proven structural performance. Engineers pick OSB wall sheathing because it’s made consistently. It has no natural defects like plywood does. Every panel meets the same strength specs.

Data center construction grows at 20% per year. These facilities lean on OSB structural systems. They need fast build schedules and exact dimensions for equipment mounting. Structural Insulated Panels (SIPs) with OSB skins give you both. Panelized building systems get you faster dry-in times. They need less onsite labor. They beat traditional stick framing for consistency.

Floor Systems: Subfloor Performance

Floor sheathing takes point loads and spread-out weight. Tongue-and-groove OSB panels rated “Sturd-I-Floor” span 19.2 or 24 inches between joists. No Extra underlayment needed. The perpendicular strand layers stop deflection creep—that slow sagging over years.

Commercial and industrial jobs push these panels harder. Manufacturing facilities face 2.6% sector decline in 2026. But they keep updating existing spaces. Heavy-duty OSB flooring handles forklift traffic and equipment loads that crush standard residential panels. Thickness goes up to 23/32 inch or more. Edge support becomes required. But the cost-performance ratio still wins against concrete or steel decking for many jobs.

Engineered Lumber Components

I-beam making uses a lot of OSB. The webs of engineered joists use OSB because it has consistent thickness and shear strength. This creates reliable load transfer between top and bottom chords. These parts span longer distances with less material than solid lumber joists.

The construction labor crisis makes OSB more vital. Construction needs 499,000 more workers in 2026. 92% of contractors struggle to hire. Prefab OSB structural systems cut field labor hours. Educational and healthcare construction drives nonresidential starts up 13% in 2025. These projects now use panelized wall and roof units that come with OSB sheathing attached.

Public safety facilities growing in 2026 need fast construction timelines. OSB’s availability, steady quality, and fit with modern building systems make it the go-to structural sheathing. The commercial sector’s 3.9% rebound depends on construction methods that use OSB’s speed-to-occupancy benefits.

Interior and Non-Structural Applications

Designers found Oriented Strand Board years before Instagram made it trendy. This material takes over interior spaces where looks matter more than load-bearing strength. Modern homes prove this shift—44.2% of interior wall sheathing now uses OSB. Compare that to just 11.2% plywood. This isn’t random. Builders choose OSB for three reasons: cost, availability, and looks.

Interior Partition Systems

Home builders frame interior walls in clear patterns. FEMA P-58 data shows 73% of modern homes use 2×4 studs spaced 16 inches apart for interior walls. Another 17% goes to 2×6 framing at the same spacing. These walls don’t carry loads. They need sheathing that stays flat, cuts clean, and costs less.

A typical 2,000-square-foot home contains 200-250 linear feet of interior partition walls per story. Most homes have one story (48%) or two stories (49%). That’s 400-750 linear feet of interior wall per house. OSB saves you $150-300 per home compared to plywood for the same coverage.

Non-Structural Design Considerations

Interior work tracks different numbers than structural sheathing. Story drift ratios show how partitions move during earthquakes. Peak floor speeds affect ceiling systems and raised computer floors. But normal use focuses on three things: stable surfaces, strong screw hold, and impact resistance.

Commercial offices use OSB for core walls around restrooms, elevator shafts, and storage areas. The core design keeps utilities in one zone. OSB panels fit between finished surfaces. Ground floor spaces—cafeterias, loading docks, service halls—get benefits from OSB’s strength against punctures and size stability.

OSB works with different spacing too. Most homes keep 24-inch-on-center framing under 10% of wall area. But floor systems often use 19.2-inch and 24-inch joist spacing for support. OSB panels rated for these spans stop callbacks about sagging or bending that cheaper options cause.

Installation Best Practices and Technical Specifications

Oriented Strand Board demands respect during installation—treat it poorly and you’ll spend months fixing callbacks. A solid installation versus a failing one? It comes down to proven techniques and understanding the material’s limits.

Pre-Installation Preparation and Site Conditions

Store OSB panels flat on blocking at least 4 inches off the ground. Stack them in covered areas away from direct moisture. Even OSB/3 panels rated for humid conditions need protection before you install. Wet panels lose 30-40% of their strength during drying. That damage stays permanent.

Check moisture content before you start. OSB should show 8-12% on a moisture meter for interior work. Anything above 15%? You wait. Let panels adjust to the job site for 48-72 hours before installation. This stops expansion problems after you nail everything down.

Temperature matters during glue application. Work between 40°F and 85°F for proper bonding. Cold weather slows drying times. Hot conditions make glue set too fast for proper setup.

Cutting and Handling Techniques

Use carbide-tipped saw blades with at least 40 teeth for clean cuts. The resin in OSB dulls standard steel blades within hours. Support both sides of the cut line. The cross-layered strands splinter without proper backing.

Cut panels face-up with circular saws. Face-down for table saws. This puts the cleanest edge where it shows. Mark cut lines clearly—OSB’s rough surface hides pencil marks under sawdust.

Handle panels from the edges, never the middle. A 4×8 sheet that bends during transport creates tiny cracks. You won’t see them until panels fail inspection. Use two people minimum for sheets thicker than 7/16 inch. Three people for anything 23/32 inch or thicker.

Fastening Requirements and Spacing Standards

Panel edges need fasteners every 6 inches. Field areas (the middle sections) need 12-inch spacing. Use 8d common nails (2.5 inches long) for panels up to 1 inch thick. Ring-shank or spiral-shank nails give you 40% better holding power in high-wind zones.

Keep fasteners 3/8 inch from panel edges minimum. Closer placement splits the strands and destroys edge strength. Set pneumatic nailers to 100-120 PSI. This drives nails flush without going too deep. Nails driven too deep crush the wood fibers. This cuts holding strength by 25%.

Screw installations need different specs. Use #8 screws with fine threads for best grip. Pre-drill holes within 2 inches of panel edges to stop splitting. Space screws 8 inches on edges, 12 inches in the field. This matches the strength of nailed installations.

Expansion Gap Critical Measurements

Leave 1/8-inch gaps between panel edges under normal conditions. End joints need 1/4-inch spacing. These aren’t suggestions—they’re must-dos. OSB expands 0.002 inches per inch of panel width for each 1% moisture increase. A 4-foot-wide panel without proper gaps will buckle as humidity rises.

Tongue-and-groove panels still need end-joint spacing. The interlocking edges handle side-to-side movement. But length changes need that 1/4-inch gap at cross joints. Metal H-clips between panels keep spacing right. Plus, they add support between frame members.

Weather Protection Protocols

Cover installed OSB within 48 hours if rain threatens. Water-resistant doesn’t mean waterproof. Tarps need secure tie-downs that won’t flap and scratch the surface. Weight edges properly—wind-blown tarps cause more damage than light rain.

Wet panels need full drying before covering with house wrap or finish materials. Trapped moisture creates perfect conditions for mold growth and panel failure. Feel the surface—if it’s cool to touch compared to the air around it, moisture stays inside.

Put weather-resistant barriers on right after roof and wall sheathing goes up. These barriers protect OSB from long exposure while letting it dry properly. Skip this step? You’re risking the building’s structural strength.

Performance Advantages vs Alternative Materials

Oriented Strand Board costs 15-25% less than plywood sheets of equal thickness. That price gap adds up fast on construction projects. A standard 7/16-inch OSB sheathing panel runs $10-15. The same size in CDX plywood? You’ll pay $14-20. A typical home needs 60-80 sheets for sheathing. That’s $240-400 in savings right there.

Dimensional Stability That Matters

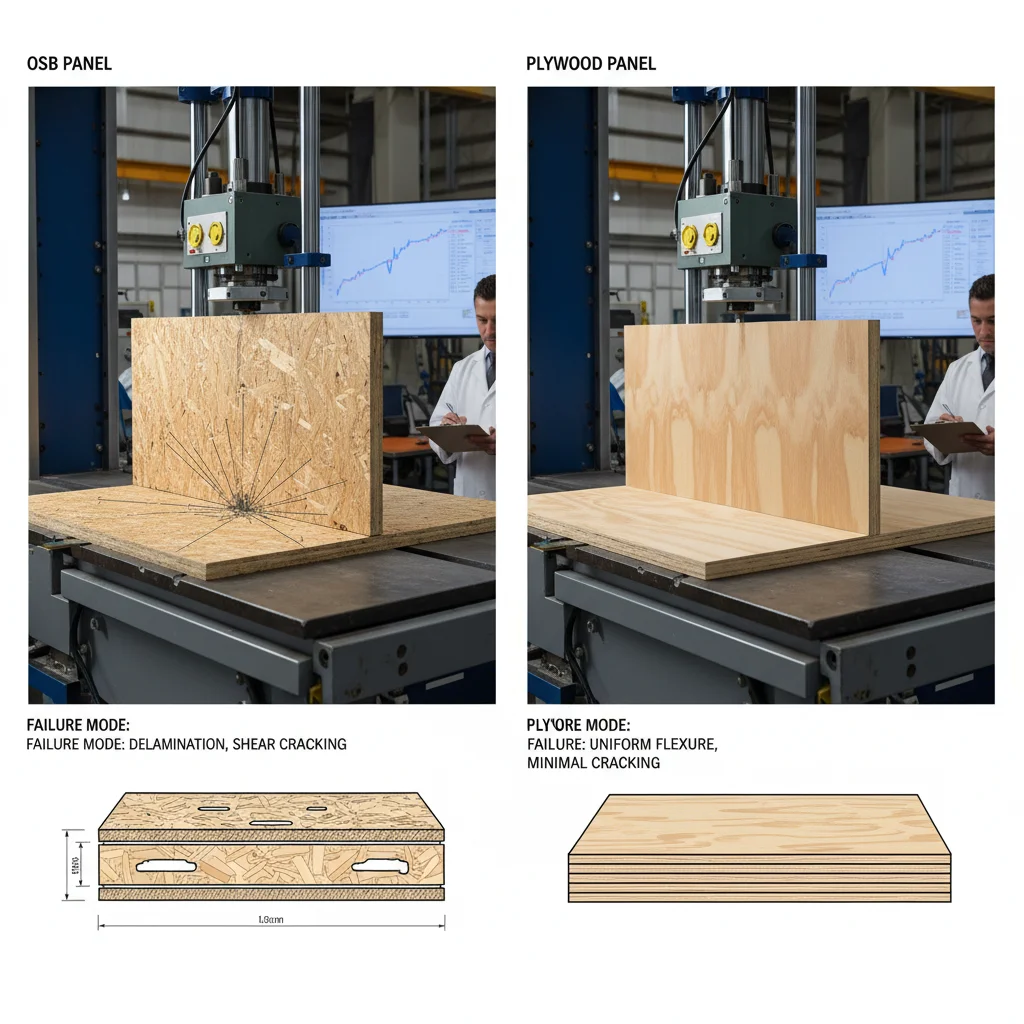

OSB stays flatter than plywood under the same conditions. The cross-oriented strand layers stop natural wood movement. Plywood uses veneer layers that follow grain direction. Those veneers still have full grain patterns. They want to move. OSB breaks wood down to individual strands. This stops directional bias.

Warping tests show the difference. Store both materials in 75% humidity for 30 days. Plywood edges curl up 3-5mm on a 4×8 sheet. OSB? Maybe 1-2mm of total movement. You get fewer callbacks about wavy roof lines or uneven walls.

Strength Distribution Without Weak Spots

Plywood hides problems under its face veneers. Knotholes, voids, and grain runout create random weak zones. A fastener pulls through or a panel cracks under load. That’s how you find them. OSB eliminates that lottery. Every square inch gives you the same strength. The manufacturing process grinds away natural defects. What you see on the surface runs through the entire thickness.

Panel ratings prove this. An OSB/3 panel rated for 24-inch roof spans carries that load anywhere you place it. Plywood with the same rating? Performance changes based on which part of the tree created each veneer layer.

Limits and Environmental Issues

Oriented Strand Board won’t fix every building problem. This material has real limits. These limits affect how it performs, how long it lasts, and its environmental impact. Ignore these limits and you’ll lose money. You’ll also face structural problems later.

Moisture Damage Is the Main Problem

OSB/3 panels handle humidity better than OSB/1 or OSB/2 grades. But “moisture resistant” doesn’t mean waterproof. Long-term water exposure causes swelling that never reverses. Panel edges soak up moisture 200-300% faster than flat surfaces. Take a standard 7/16-inch panel. Expose it to standing water for 24 hours. The edges swell 15-20%. That swelling never goes back to normal—even after it dries out.

Coastal building zones face this problem all the time. Salt air speeds up moisture getting through tiny gaps in the resin bond. Florida building inspectors reject 12-18% of OSB installations each year. The reason? Water damage from poor protection during building. The fix? You need to replace the panels. You can’t repair them.

Edge Sealing Adds Labor Costs

Protect those weak edges or pay the price. Quality edge sealants cost $8-12 per tube. Each tube covers 40-50 linear feet. A typical wall sheathing job needs 6-8 tubes just for edge treatment. That’s $60-80 in material plus 2-3 hours of labor time. Skip this step in humid climates? You’ll see edge swelling within 18 months.

Span Limits Compared to Other Options

Standard 7/16-inch OSB maxes out at 24-inch roof joist spacing. Need longer spans? You need thicker panels or switch to I-joists and LVL beams. A 23/32-inch panel costs 40% more than 7/16-inch material. Other lumber options span 30-50% farther. But they cost 60-80% more than similar OSB setups.

Surface Texture Makes Finishing Hard

That unique strand pattern makes OSB easy to spot. It also creates problems for direct paint or stain jobs. The rough surface shows through thin finishes. Proper surface prep needs sanding with 80-grit paper, then 120-grit for smooth finishes. Add primer-sealer that costs $25-35 per gallon. Each gallon covers 250-300 square feet. You’re looking at $0.10-0.14 per square foot just for surface prep materials before paint.

Formaldehyde Emissions Affect Indoor Air

Modern OSB making uses phenol-formaldehyde and polymeric methylene diphenyl diisocyanate (pMDI) resins. Formaldehyde off-gassing peaks during the first 90 days after you install it. California’s CARB Phase 2 limits formaldehyde emissions to 0.11 ppm for composite wood products. Standard OSB panels emit 0.05-0.09 ppm under controlled conditions. Poor airflow during building pushes levels higher.

Sensitive people report headaches, breathing problems, and eye discomfort in new buildings using OSB. The fix? You need mechanical ventilation running 24/7 for the first three months. That’s 2,160 kWh of electricity use at $0.12-0.15 per kWh. This adds $260-325 to energy costs for proper air exchange.

Hard to Reuse and Recycle

Pull OSB panels off a building for renovation work? The nail holes, edge damage, and moisture exposure make reuse almost impossible. Recycling facilities take OSB, but pickup options are limited. Just 22% of construction waste facilities in the US process OSB apart from mixed wood waste. The rest burns it or sends it to landfills.

Recycled OSB turns into low-grade particleboard or gets ground into landscape mulch. Neither use captures the energy and resources put into making structural panels. This one-way use model goes against circular economy ideas gaining ground in green building.

Where Materials Come From Raises Green Questions

OSB production uses small-diameter trees and mill leftovers—sold as using “waste” wood. Reality is more complex. Demand for OSB strand material drives dedicated logging of young trees in managed forests. These forests don’t often match old-growth variety. A typical OSB mill uses 150,000-200,000 tons of wood each year. That’s about 6,000-8,000 acres of managed pine plantation each year per plant.

Certification systems like FSC and SFI provide some oversight. But just 35-40% of OSB sold in North America has third-party forest certification. The rest comes from unverified sources with unknown practices.

Making OSB Uses Lots of Energy

Making OSB needs serious heat and pressure. Production uses 2.5-3.2 million BTUs per thousand square feet of finished panel. Natural gas powers most pressing work. This creates direct greenhouse gas emissions. A single OSB plant makes 45,000-60,000 tons of CO₂ equal each year just from heat energy use.

Compare this to solid lumber: sawmilling uses 0.8-1.2 million BTUs per thousand board feet. OSB’s carbon footprint runs 200-250% higher than regular lumber for the same coverage. The upside comes from using smaller trees and wood scraps. But the energy cost stays real.

Selection Guide: Choosing the Right OSB Type

The right panel grade turns an average project into one that lasts decades. Pick the panel that matches your actual site conditions. Your budget and building strength depend on this choice.

Match Panel Grade to Moisture Reality

OSB/1 belongs in furniture workshops and craft studios. Use this grade for interior cabinets, drawer bottoms, and decorative panels. Humidity stays low in these spaces. Relative humidity above 65%? You’ve picked the wrong material. Cost savings vanish fast. Panels warp within months.

OSB/2 works for structural framing in climate-controlled spaces. Interior load-bearing walls in homes with reliable HVAC systems? This grade performs well. It supports 30 psf live loads at 16-inch on-center spacing. It won’t exceed the 1/180 deflection limit. Desert climates and dry regions make OSB/2 a smart budget choice. Humid basements or coastal projects need a better grade.

OSB/3 dominates construction sites for good reason. This workhorse handles moisture changes during building and after. Relative humidity swings between 40-85%? Structural strength stays solid. Wall sheathing, roof decking, and subflooring in most climates work well with OSB/3. The 15-20% price increase over OSB/2 prevents callbacks. You won’t need to replace panels.

OSB/4 tackles extreme conditions. Industrial flooring under forklift traffic needs this grade. Roofing systems in humid regions justify the cost. You’ll pay $18-25 per 4×8 sheet for 7/16-inch thickness. That’s the highest cost tier. But modulus of rupture reaches 3,000-4,000 psi. This matches premium plywood performance. Heavy-duty jobs in moisture-prone areas make this expense worthwhile.

Calculate Load Requirements Before You Buy

Span ratings determine which thickness works. A 24/16 rating means 24-inch maximum spacing for roof joists. Floor joists need 16 inches. Standard 7/16-inch panels handle wall studs spaced 24 inches on-center. Need longer spans? Step up to 23/32-inch or thicker panels.

Structural 1 designation signals superior bending stiffness. These panels deliver higher shear values. Industrial buildings, mobile home construction, and high-stress jobs need these. The modulus of elasticity runs 0.7-1.2 × 10⁶ psi. This is built for tough structural work.

Check edge support availability. Panels with blocking between joists carry more load. Unsupported edges can’t handle as much weight. Tongue-and-groove designs provide built-in edge support. You won’t need separate blocking on floor systems.

Verify APA Certification Always

Every legitimate Oriented Strand Board panel carries the APA trademark. This stamp confirms compliance with U.S. Voluntary Product Standard PS2. Three core tests happen: structural strength, dimensional stability, and bond durability.

Panels without APA certification might look identical. They won’t perform the same. Strict testing separates certified panels from knockoffs. Inspection agencies verify consistent quality across production runs. Your building inspector will check for this trademark. Make sure it’s there before installation starts.

Panel Dimensions and Practical Considerations

Standard sheets measure 4×8 feet. Actual dimensions run 3’11-7/8″ × 7’11-7/8″. That 1/8-inch reduction provides essential expansion spacing. Installation requires this gap. Available thicknesses range from 7/16 inch up to 1-1/8 inches. This covers basic sheathing to heavy-duty industrial flooring.

The APA Rated Sturd-I-Floor category cuts out separate underlayment. These panels combine subfloor and underlayment in one installation. This cuts labor costs and material waste. Thickness options of 19/32, 23/32, and thicker sizes handle standard residential floor loads. No additional layers needed.

Conclusion

Oriented Strand Board has changed. It started as a backup option. Now it’s a smart choice that offers strength and good looks.

You might be covering a whole house. Maybe you’re building custom furniture. Or looking for affordable interior options. Either way, knowing your OSB types helps. OSB/1 works for dry spaces. OSB/4 handles heavy loads. This knowledge helps you pick what fits your project.

The beauty of oriented strand board? It’s honest. Those visible wood strands aren’t mistakes. They add texture and character. Plus, they show that eco-friendly building can still look great. Moisture control is important. You need the right Installation Methods too. But learn about exposure ratings, thickness specs, and panel types. You’ll feel confident choosing OSB.

What’s next? Take your project details to a good supplier. Ask about certified panels that match your local codes. Request samples – don’t hesitate. Touch the material. Picture it in your space. Smart building choices start here.