Spc Flooring thickness isn’t about spec sheet numbers. It’s about matching performance to real project needs.

You’re installing floors in a busy retail space? A cozy bedroom? A high-traffic commercial hallway? The difference between 4mm, 5mm, and 6mm matters. Your installation budget depends on it. So does how well those floors perform five years from now.

This SPC flooring thickness comparison covers what contractors and homeowners care about. Upfront costs versus long-term value. Which thickness works best for different spaces. How each one handles imperfect subfloors. What to expect for durability and noise control.

You’ll know which thickness fits your specific project. Plus, why settling for “standard” might cost you more than you think.

SPC Flooring Thickness Guide: 4mm, 5mm, 6mm

You can find four common SPC flooring thickness options: 3.2mm, 4mm, 5mm, and 6mm. Each one fits different uses. Think about traffic patterns, subfloor conditions, and your budget.

4mm SPC Flooring: The Budget-Conscious Choice

4mm thickness gives you the best price-to-performance ratio. You get solid structure without paying extra.

Best Applications:

– Low-traffic residential spaces

– Rental properties

– Office environments

– Light-traffic shopping areas

This thickness works alone in moderate traffic zones. Got a living room or sports area? Add an underlayment liner for better comfort. The thinner profile cuts easier during installation. DIY installers love this feature.

Critical limitation: 4mm SPC needs a very flat subfloor. It bends over bumps. This creates weak spots. Use a wear layer of at least 4 mil (0.004 inches). This gives you 5+ years of service life.

Example products: Hardwood SPC 3210, Rigid Core Oak LXS2023207, Anti-Bacteria Soundproof LXS2023368

5mm-6.5mm SPC Flooring: The Sweet Spot

The 5mm to 6.5mm range works best for most homes and light commercial spaces. You get a good mix of cost, comfort, and durability.

Typical options:

– 5mm systems: Studio SPC features a 4mm core with 1mm integrated foam pad

– 6mm systems: Sound-Tec combines 4.5mm core with 1.5mm foam underlayment

Subfloor tolerance: Maximum 3/16 inch (5mm) deflection over 6 feet (1.8m). This handles minor surface bumps. Your floor still performs well.

6mm-8mm SPC Flooring: Heavy-Duty Performance

Thicker 6mm to 8mm SPC flooring handles busy commercial spaces. Durability and sound control are must-haves here.

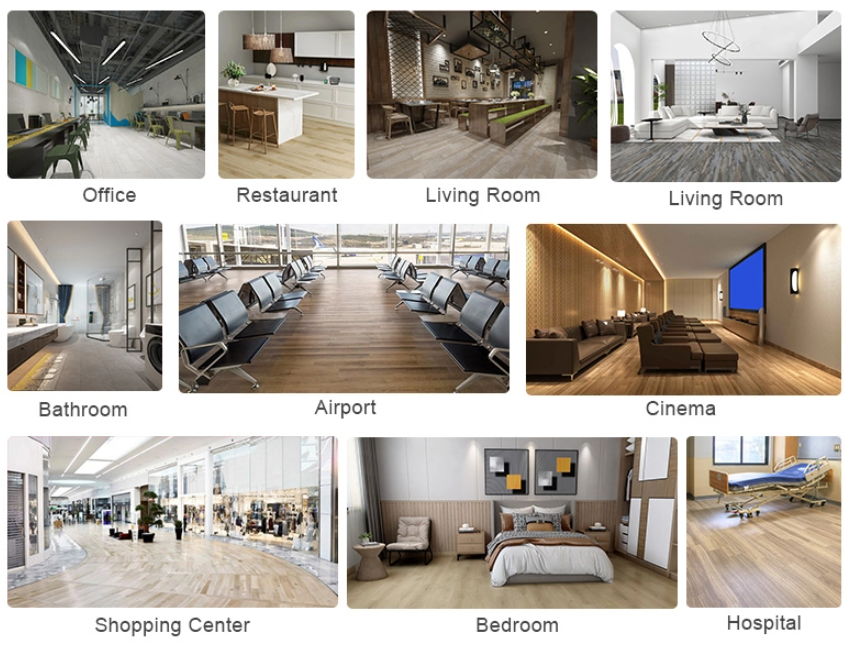

Commercial Applications: – Schools and hospitals – Shopping mall corridors – Hotel lobbies – Public gathering spaces

These products last 20+ years under normal commercial use. The extra thickness covers subfloor bumps up to 1/4 inch (6mm) over 6 feet. This cuts down on prep costs.

Example product: Anti-Scratch Vinyl Plank LXS2023128 (6mm)

1. Cost & Value :SPC Flooring Thickness vs Cost & Longevity (1,000 sq.ft example)

| Floor Thickness | Installed Cost per sq.ft | Total Project Cost | Expected Lifespan | Amortized Annual Cost | Key Benefits / Notes |

|---|---|---|---|---|---|

| 4mm | $2.50–$4.00 | $2,500–$4,000 | 6–8 years (busy hallway) | $500/year (avg. 7 yrs) | Lower upfront cost; shorter lifespan; higher annual cost due to earlier replacement |

| 5mm | $3.50–$5.50 | $3,500–$5,500 | 10–12 years | $292–$458/year | Balanced cost vs durability; moderate wear resistance and sound dampening |

| 6mm+ | $5.00–$7.50 | $5,000–$7,500 | 15–20 years | $325–$500/year (avg. 17 yrs) | Denser structure, better sound dampening, tougher wear layer; lower annual ownership cost; fewer re-installation expenses |

Key Takeaways

Thicker floors = higher upfront cost but longer lifespan and lower annualized cost.

4mm floors may be suitable for low-traffic areas or budget projects.

6mm+ floors protect investment in high-traffic areas, reducing reinstallation and labor costs.

Match thickness to actual traffic and usage, not just the “highest spec.”

2. Recommended Applications

Floor thickness makes or breaks your SPC installation. Traffic levels, subfloor condition, and sound needs determine which thickness works best for each space.

4mm SPC Flooring Applications

Primary residential zones:

– Bedrooms and guest rooms with under 500 steps per day

– Home offices with rolling chairs over protective mats

– Closets and storage areas you don’t use often

– Seasonal rental properties on 3–5 year replacement cycles

Light commercial environments:

– Private office suites with carpeted zones that absorb hallway traffic

– Boutique retail fitting rooms and display areas (skip the main aisles)

– Medical exam rooms in low-volume clinics (under 15 patients per day)

The 4mm profile works great on tight budgets. You need a very flat subfloor though—tolerance under 1/8 inch per 10 feet. This prevents minor bumps from showing through. Add 0.5mm cork underlayment in second-floor bedrooms. You’ll meet basic sound ratings without paying for thicker flooring.

Skip 4mm in these spots: Entryways, kitchens, laundry rooms, or spaces with rolling carts, pet claws, or water sitting for 30+ minutes.

5mm-6mm SPC Flooring Applications

Whole-home installations:

– Open-concept living areas that combine kitchen, dining, and living zones

– Finished basements over concrete with moisture barriers

– Main-floor bathrooms (powder rooms and full baths with proper sealing)

– Mudrooms and foyers getting 1,000–2,000 steps per day

Multi-family housing:

– Apartment units needing IIC 50+ and STC 50+ ratings for noise control between floors

– Condo hallways with moderate traffic (under 100 units per building)

– Townhome staircases paired with 1.5mm acoustic pad

Commercial light-duty:

– Boutique hotels with guest rooms and small lobbies (under 50 rooms)

– Corporate training rooms with movable furniture on glides

– Daycare centers in play zones over 2mm foam underlayment for fall protection

This thickness handles bumpy subfloors better. You can skip pre-leveling in 70% of homes—it tolerates deviations up to 3/16 inch. The underlayment cuts 12–18 dB of impact noise. That’s crucial for second-story rooms and shared walls.

6mm+ SPC Flooring Applications

High-traffic commercial:

– Retail main aisles in stores with 500+ customers per day

– Hospital corridors and patient rooms needing Class 32–33 commercial ratings

– School hallways and cafeterias handling wheeled carts and 1,000+ students per period

– Hotel lobbies in properties with 100+ rooms and conference spaces

Specialized residential:

– Home gyms with free weights (add 3mm rubber underlayment for extra impact protection)

– Pet boarding areas in homes with several large dogs

– Wheelchair-accessible homes needing firm, stable rolling surfaces

The 6mm structure gives you wear layers of 20 mil (0.5mm) or thicker. Commercial warranties stretch to 15–20 years. The core density reaches 2,100 kg/m³. This supports 400+ PSI loads—vital under vending machines, retail fixtures, and institutional gear.

Subfloor forgiveness: This thickness handles up to 1/4 inch variation over 10 feet. You’ll save $0.75–$1.50 per square foot on leveling compound in renovation jobs. The extra thickness hides seams in plywood and small cracks in old concrete.

3. Subfloor Flatness & Stability

SPC flooring won’t fix a wavy subfloor. Thicker planks give you more forgiveness—but industry standards still matter.

ASTM F710 sets the baseline for concrete subfloors: maximum 3/16 inch (4.8mm) deviation over a 10-foot straightedge. Place that straightedge anywhere on your floor. The gap underneath can’t exceed 3/16 inch. Most resilient flooring makers follow this spec. Some tighten it to 1/8 inch in 6 feet for premium installations.

Wood subfloors use NWFA guidelines. Floating or glue-down installations need 1/8 inch in 6 feet or 3/16 inch in 10 feet flatness. Using mechanical fasteners longer than 1½ inches? You get a bit more tolerance: 3/16 inch in 6 feet or 1/4 inch in 10 feet.

How SPC Thickness Handles Subfloor Bumps

4mm SPC flooring demands near-perfect prep. Small surface bumps show through the thinner core. You see them. You feel them underfoot. Budget $0.75–$1.25 per square foot for self-leveling underlayment (SLU) to hit that 1/8 inch tolerance. Skip this step? Your floor develops weak spots within 18–24 months.

5mm-6mm SPC flooring bridges small gaps. The denser core hides bumps up to 3/16 inch without pre-leveling. This cuts prep costs by 40–60% on renovation jobs. You still need to grind down high spots. Fill deep valleys too. But those minor dips in old concrete? The flooring handles them.

6mm+ commercial-grade SPC tolerates up to 1/4 inch variation over 10 feet. The rigid core spreads weight across a larger area. This stops point loading that causes cracks or hollow spots. Skip aggressive subfloor grinding and save $1,200–$2,000 on a 1,000-square-foot project.

Check flatness with a 10-foot straightedge. Run it in multiple directions across each room. Any gap over 3/16 inch needs attention. Mark high spots for grinding. Fill low areas with patching compound or SLU rated for ≤1/8 inch plane variation. Take photos of problem zones before installation—this protects your warranty claims if issues pop up later.

Some commercial projects need FF/FL numbers (Floor Flatness/Floor Levelness per ASTM E1155). General office spaces target FF 25/FL 20. High-traffic retail or warehouse spaces need FF 30/FL 30 or higher. These specs keep your floor stable under heavy loads and equipment.

4. Durability & Lifespan

SPC flooring thickness determines how many years you get before replacement. The wear layer, core density, and total thickness resist scratches, dents, and regular use.

4mm SPC flooring lasts 5–10 years in homes with normal foot traffic. The thinner core (3.5–4mm) handles light use well. Bedrooms, closets, and quiet offices stay protected. Use this thickness in busy kitchens or entryways? You’ll see visible wear around year 4–5. The wear layer on budget 4mm options runs 12–20 mil (0.3–0.5mm). That’s enough for Class 23 residential ratings. But it fails under commercial loads.

Real-world limitation: A rental property kitchen with 4mm SPC shows traffic patterns after 18–24 months. High-traffic zones near the sink and stove fade first. The thinner core flexes more under point loads. Micro-cracks form. They spread over time.

5mm-6mm SPC flooring delivers 12–20 year lifespans in homes and 8–12 years in light commercial use. The core thickness jumps to 4.5–5mm. Wear layers reach 20–30 mil (0.5–0.76mm). This supports Class 31–32 commercial ratings. Apartment hallways, hotel guest rooms, and retail fitting rooms get this performance.

These mid-range products use virgin PVC and calcium carbonate cores with densities around 1,950–2,050 kg/m³. The structure holds up under furniture legs and wheeled office chairs. A 1,000-square-foot living room with 5.5mm SPC flooring shows minimal wear after 8 years of regular use. Just maintain it properly and avoid standing water.

6mm+ commercial-grade SPC lasts 15–25+ years under heavy traffic. Hospital corridors, school cafeterias, and retail main aisles need this durability. The wear layer thickness hits 30–40 mil (0.76–1.0mm). Core density reaches 2,100+ kg/m³. These products carry Class 33–34 commercial ratings. They support loads exceeding 400 PSI.

Cost-per-year analysis shows the value gap:

– 4mm option at $3,500 ÷ 7 years = $500/year

– 5mm option at $4,500 ÷ 15 years = $300/year

– 6mm option at $6,500 ÷ 20 years = $325/year

The 5mm thickness offers the lowest annual ownership cost for most home projects. The 6mm option makes sense for commercial spaces. Replacement labor costs matter there. Shutting down for re-installation disrupts business.

Warranty coverage reflects real durability: 4mm products carry 10–15 year residential warranties. No commercial coverage. 5mm–6mm options include 15–25 year residential warranties plus 5–10 year light commercial protection. Premium 6mm+ flooring offers lifetime residential warranties and 15–20 year commercial guarantees.

5. Comfort & Sound

Underfoot feel and noise control separate good flooring from regret. SPC thickness affects both. Most installers miss this until complaints start.

4mm SPC flooring feels firm. The thin core (3.5–4mm) sits close to the subfloor. Each footstep goes straight to the structure below. You feel minor subfloor flaws through the planks. Small bumps that passed the 3/16 inch tolerance? You notice them barefoot.

Sound transmission is the bigger problem. A 4mm floor alone offers minimal acoustic dampening. Expect IIC 28–32 and STC 30–35 ratings. That’s below code for apartment buildings. Most areas require IIC 50+ and STC 50+ between floors. You’ll need separate underlayment to meet those specs.

Add 2mm foam or cork underlayment beneath 4mm SPC. Your ratings jump to IIC 50–55 and STC 48–52. The cost? Another $0.35–$0.65 per square foot. Budget $350–$650 extra on a 1,000-square-foot project. Skip it in a second-floor bedroom? Downstairs neighbors hear every footstep, dropped item, and furniture drag.

5mm–6mm SPC flooring with integrated padding delivers better comfort. Many 5.5mm products include 1mm–1.5mm attached foam or cork backing. The composite structure absorbs impact better. Walking feels softer than bare 4mm planks. IIC ratings reach 50–58 and STC ratings hit 50–55 without separate underlayment. You meet building codes. Plus, you save installation time.

The thicker core (4.5–5mm) creates more distance between your feet and the subfloor. Minor surface bumps disappear. A small hump that felt obvious on 4mm SPC vanishes under 5.5mm planks with padding.

Commercial 6mm+ SPC focuses on durability over cushion. These products use dense, rigid cores—2,100+ kg/m³—to support heavy loads. Comfort ranks second to structural stability. This trade-off makes sense in retail aisles, hospital corridors, and school hallways. Staff and visitors wear shoes. The shoes provide cushioning.

Sound control stays strong with premium 6mm SPC. Products made for apartments include 2mm–3mm acoustic backing. Ratings reach IIC 60–67 and STC 55–60. This handles rolling carts, dropped equipment, and high foot traffic. Spaces below stay quiet.

Real project example: A 1,200-square-foot second-floor condo switched from 4mm SPC (with separate 2mm underlayment) to 5.5mm SPC with integrated 1.5mm padding. Material cost rose $480 ($0.40/sq ft difference). Installation time dropped 3 hours. No separate underlayment to roll and tape. Noise complaints from the downstairs unit stopped. Impact noise dropped by an estimated 15–18 dB based on manufacturer IIC testing.

Choose thickness based on what’s below and above your floor. Installing over a concrete slab on grade? Comfort matters more than sound. Pick 5mm–6mm with integrated padding for better underfoot feel. Installing a second-floor apartment? Sound ratings become critical. Verify your product meets local IIC and STC minimums. Don’t trust thickness alone.

Contractor Takeaway

SPC flooring thickness affects your material procurement, labor scheduling, and bid accuracy. Treat it like any critical specification that drives job costs and client satisfaction.

Quantify your thickness requirements at the start of the takeoff process. Measure square footage for SPC flooring installations. Add a dedicated column for thickness specification alongside the standard SF count. A 2,000 SF commercial office renovation might break down like this: 1,200 SF of 6mm SPC in corridors and reception (high traffic), 600 SF of 5mm in conference rooms (moderate use), and 200 SF of 4mm in storage areas (minimal traffic). This detailed approach prevents ordering a single thickness for mixed-use spaces. That mistake costs money.

Build your unit pricing with the hidden costs baked in. Your material cost per SF jumps 40–60% from 4mm to 6mm product. Don’t stop there. Factor subfloor prep into your labor hours. 4mm installations demand near-perfect flatness (1/8″ in 6′). This adds 2–4 hours of grinding and leveling per 500 SF. Specify 6mm SPC that tolerates 1/4″ variance? You’ve just cut prep time by half. Labor costs drop too. Calculate installed cost including these preparation hours. Don’t just count material and basic installation.

Use thickness specs to manage client expectations and change orders. A client pushes for 4mm to hit a budget number? Document the limitations in your proposal: “4mm SPC suitable for light-traffic areas. High-traffic zones require 6mm upgrade at $X.XX/SF to meet 15-year performance expectations.” This creates a clear audit trail. Warranty claims or premature wear complaints surface three years into a project? You’re covered.

Leverage thickness data for value engineering discussions. Present clients with a cost-per-year analysis during bid review. Show them this: “The 6mm option costs $2,000 more upfront but delivers $118/year lower ownership cost over 20 years versus replacing 4mm product at year 8.” Hard numbers close value-engineering conversations faster than vague “better quality” claims.