Australia’s MDF Industry Overview – Leading Sustainable and Certified Suppliers

Australia’s MDF industry is driven by a strong focus on sustainability, certification, and precision manufacturing. Local and international suppliers alike are investing in greener production and advanced fiberboard technology to meet rising demand from the furniture, construction, and interior design sectors.

What stands out in Australia’s MDF supply chain is the balance between technical consistency—with densities ranging from 650 to 850 kg/m³ and sheet sizes up to 3600 mm—and environmental performance, such as E0 and CARB2 compliance. Annual production across leading suppliers now exceeds several hundred thousand cubic meters, reflecting both growing domestic needs and the expansion of export capacity.

In this report, I’ve reviewed several of the most reputable MDF suppliers in Australia — comparing their sustainability credentials, product ranges, certifications, and industrial scale — to help builders, designers, and procurement professionals choose the best partner for their projects.

FA Mitchell – One of Top MDF Suppliers Australia I Recommend

Their Wide Range of MDF Products

Sheet sizes: 1800×1200mm up to 3600×1800mm

Thickness options: 3mm to 32mm

Formats: Standard and Moisture Resistant (MR)

Decor finishes: You can get a white melamine overlay or choose from many other decorative colors.

Why I Trust Their Focus on Safety and the Environment

Their MDF is 100% sourced from Australian plantations.

I recommend their products because they have a zero formaldehyde emission rating. This makes their products safer and lower in emissions.

The EWPAA audits all their MDF to ensure it meets quality and safety rules.

Their support for green practices separates them from overseas providers. I think this is a huge plus.

Custom Services and What Makes Them Stand Out

They offer in-house cut-to-size solutions. Their team uses advanced tools like band saws, scroll saws, and jigsaws. I’ve seen them make very precise cuts, even for complex scrolled or scalloped designs.

They help you meet safety regulations for on-site MDF cutting related to dust.

I suggest their professional edge banding. They color-match it to reduce waste.

Their own trained, in-house contractors perform all custom work.

My Thoughts on Their Pricing, Reliability, and Service

I think they offer very competitive prices and great services for trade professionals.

They provide a quick turnaround on custom orders. Their shipping is reliable nationwide.

Their expert staff helps you select the right products. They can also offer good technical advice.

They supply MDF to a wide range of customers, including schools, offices, warehouses, and film sets.

Their National Network and Industry Standing

They are a member of Big River Industries. This group also includes Big River Group, Timberwood Panels, Revolution Wood Panels, and Plytech NZ.

They have a large network of offices and warehouses in Victoria, NSW, Queensland, and WA.

If your business needs a sustainable, safe, and affordable MDF supplier in Australia, I suggest FA Mitchell. From my experience, they deliver excellent quality, value, and service.

Baier – Sustainable and Certified MDF Supplier in Melbourne & Australia

Key Features and Trade Benefits

Extensive MDF Range Baier offers an impressive range of MDF boards that cover multiple thicknesses, densities, and dimensions. I found their standard options include 2 mm to 25 mm thickness, with popular sheet sizes such as 1220×2440 mm, 1220×3050 mm, and 1830×2745 mm. The boards are produced at a density range of 650 – 850 kg/m³, which ensures both surface stability and machining performance.

This variety makes it easy for builders, designers, and furniture manufacturers to source the right material for each project — whether it’s fine interior joinery or heavy-duty commercial fit-outs.

Industrial-Grade Strength

Baier’s MDF demonstrates consistent physical strength. The internal bond value typically reaches ≥ 0.55 MPa, with a modulus of rupture (MOR) above 20 MPa and modulus of elasticity (MOE) exceeding 2,300 MPa. The moisture content (5 – 10 %) and thickness swelling (< 8 %) are well-controlled, resulting in dimensional stability even under variable humidity.

Trade and Wholesale Advantages

Their trade program provides tangible value for repeat buyers, offering up to 10 % in savings for bulk purchases. Combined with factory-direct supply, Baier’s MDF delivers reliable performance at competitive pricing for both manufacturers and distributors.

Sustainable Sourcing and Environmental Certifications

FSC-Certified Materials Baier supplies MDF that meets FSC standards, confirming that the wood fibers originate from responsibly managed forests. This certification supports builders and specifiers who must meet sustainability benchmarks in public or green-certified projects.

Global GreenTag Recognition

Some of Baier’s MDF lines also carry Global GreenTag certification, one of Australia’s leading ecolabels. These certifications reinforce the company’s alignment with low-emission, health-conscious production, and environmentally responsible sourcing.

Low Formaldehyde Emissions The MDF products comply with CARB2 and E1 emission limits, ensuring safer use in interior applications such as cabinetry and wall panels.

Technical Specifications & Manufacturing Scale

| Property | Standard Value / Range | Technical Notes |

|---|---|---|

| Density | 650 – 850 kg/m³ | Standard range for high-quality MDF |

| Thickness Range | 2 mm – 25 mm | Custom thicknesses available on request |

| Common Sheet Sizes | 1220×2440 mm, 1220×3050 mm, 1830×2745 mm | Suitable for both furniture and construction applications |

| Moisture Content | 5 – 10 % | Controlled during pressing to reduce warping |

| Internal Bond (IB) | ≥ 0.55 MPa | Indicates strong fiber cohesion |

| Modulus of Rupture (MOR) | > 20 MPa | Good bending resistance |

| Modulus of Elasticity (MOE) | ≥ 2,300 MPa | High stiffness under load |

| Thickness Swelling (24 h) | < 8 % | Maintains flatness in humid environments |

Annual Production Capacity

Baier’s MDF operations maintain an annual output of roughly 60,000 m³, equivalent to about 300,000 sheets (1220×2440×18 mm).

Monthly capacity averages 5,000 m³, with production efficiency maintained above 80 % utilization even during high-demand periods.

Product Applications and Industry Examples

Baier MDF is widely used in architectural joinery, commercial furniture, cabinetry, and caravan interiors. The boards’ smooth surfaces and uniform density make them suitable for painting, veneering, lamination, and CNC machining.

Beyond standard MDF, Baier also offers decorative laminates, HDF substrates, and matching edge banding, which support both structural and aesthetic continuity in furniture production and interior design.

Alpine MDF (Wangaratta, VIC) – Sustainable Pine MDF Manufacturer

Alpine MDF in Wangaratta, VIC, is a top Australian maker of Pine Medium Density Fibreboard (MDF). The company started in 1994 and is a key player in the engineered wood business. It has a team of 90–200 employees and earns around $6.9 million in revenue each year.

My View on Their Sustainable Practices and Certifications

Alpine MDF makes over 150,000 m³ of MDF per year. I think they do a great job focusing on product quality and consistency.

The company manages its timber resources in a sustainable way. I suggest this is a great approach because it keeps their environmental impact low.

They hold both Responsible Wood Chain of Custody (EWPAA-RW-COC-1) and PEFC (PEFC/21-31-184) certifications. These are valid through 2028. These certificates prove they follow strict global standards for sustainable wood.

I have seen that these certifications apply to their Medium Density Fibreboard, High Density Fibreboard, and architectural joinery.

Technology and Modern Operations

I find it impressive that Alpine MDF uses modern manufacturing methods and advanced quality control. This helps them create new and consistent products.

To run their business communications and daily tasks, they use major software from providers like Google and Microsoft.

Product Line and Extra Services

I suggest looking at their wide range of products. They offer Pine MDF, High Density Fibreboard, primed mouldings, and flat painted panels. They added a special paint line for mouldings and panels back in 2009.

Their products serve many industries. Based on my experience, they are mostly used in furniture, cabinetry, and architectural joinery.

ForestOne – Australia’s Largest Sustainable MDF and Building Materials Distributor

Sustainability Credentials and Certifications

Responsible Wood and PEFC certified: I notice they hold both Responsible Wood and PEFC certifications. This assures me that their products come from responsible sources and sustainable production lines.

This certification covers products like MDF, engineered wood panels, plywood, particleboard, OSB, sawn wood, and veneer sheets.

I also suggest looking at their many ranges that are FSC or PEFC certified. I like that some panels are made with no added formaldehyde, silica, or resins.

Their Responsible Wood certification is valid until 21/01/2030. For me, this provides long-term confidence that their supply chain is accountable.

Wide Product Selection and Affordable Pricing

I find their MDF Standard panels have very competitive pricing. Prices range from $23.55 to $187.35 based on thickness and size. I think this makes them suitable for both budget and premium projects.

You can find popular sizes like 3660 x 1196 x 9.5mm. They also offer thicknesses of 3mm, 9mm, and 38mm.

I recommend their special ranges like DesignerOne (which is Australian-made and PEFC certified), EGGER Eurodekor, and COLOURpyne. These are great, cost-effective choices for interior projects.

For moisture resistance, I look at options like WallART panels and Weather Groove cladding, which start at $198.50. I value these products because they are easy to install and have great water resistance.

You can get high-end worktops like EGGER starting from $385.19.

I really appreciate that all of ForestOne’s interior finishes, benchtops, and linings are 100% silica-free. This is a huge plus for health and safety in any home or commercial building.

Why I Recommend ForestOne for Sustainable MDF and Panels

I strongly recommend ForestOne for sustainable MDF and panels. They offer a great mix of certified sustainability, a broad product choice, sharp pricing, and strong national logistics. This makes them a top reference for architects, builders, and designers looking for dependable MDF suppliers in Australia who care about the environment. From my perspective, their focus on recyclable, low-emission, and health-conscious materials truly makes them a standout supplier for residential and commercial projects.

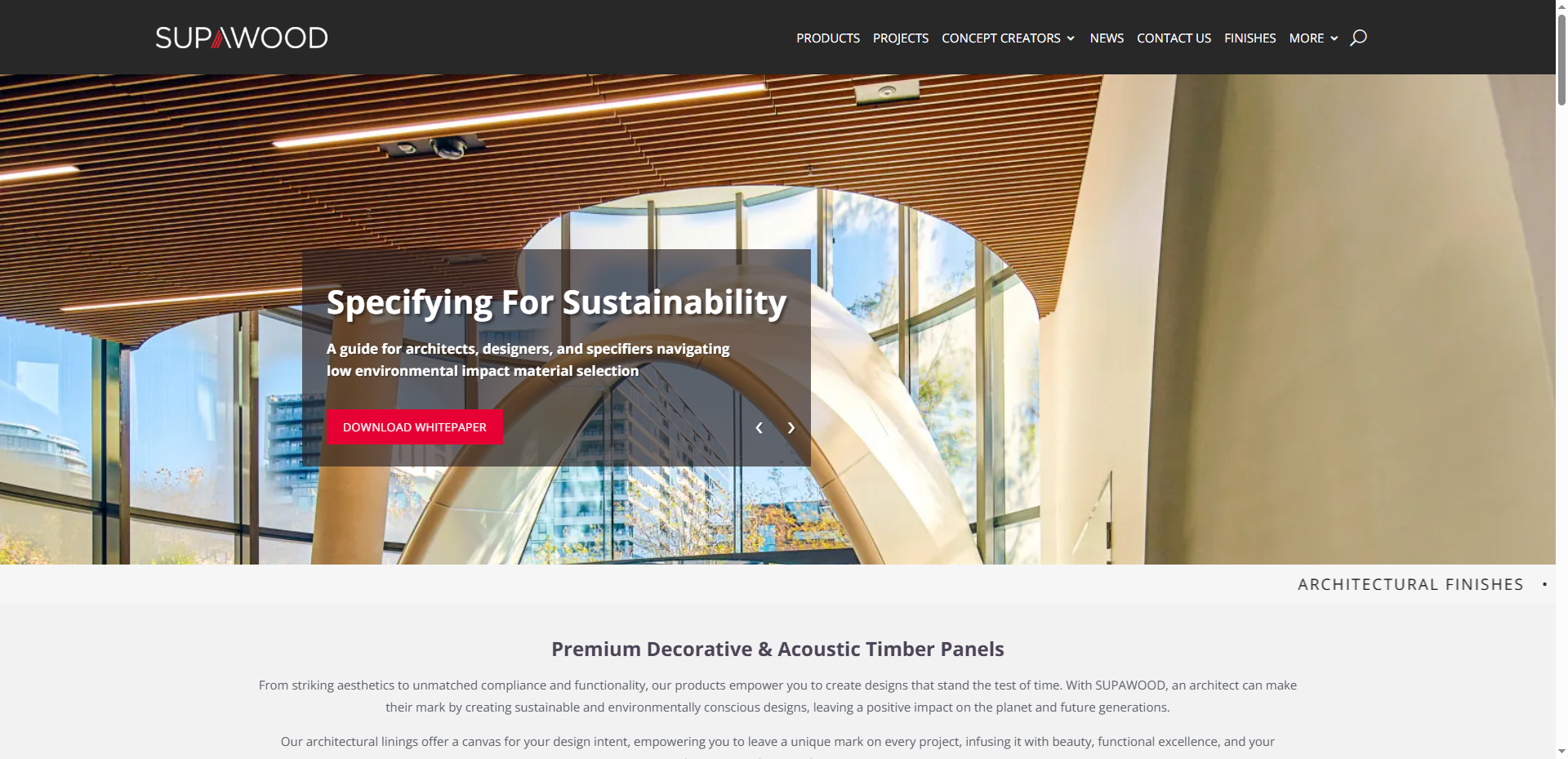

Supawood – Leading Supplier of Architectural Wall & Ceiling Lining Systems (Not Raw MDF)

Supawood’s Product Focus

Decorative Panel Systems: From my perspective, Supawood’s main business is high-quality, decorative systems for walls and ceilings. You might know their Supaline and Supaslat ranges.

Australian-Made: They make their products in Australia. They focus on good design, easy installation, and great sound control.

Pre-finished & Modular: The panels arrive ready for you to install. I like that they often include hidden or visible fixing systems. This makes the job fast and clean.

Product Types – What Sets Supawood Apart

Supaline: This product is a decorative panel for inside spaces. It gives a high-end look. I’ve noticed their materials don’t list MDF as the base material. This makes them very different from suppliers who just sell MDF panels.

Supaslat: These are timber slat systems that come in modules. I think their best feature is how you can customize them. You can use them for curved walls or unique feature walls. Again, the product details don’t mention MDF. They highlight that timber is the main material.

Not a Direct MDF Supplier

No Raw MDF Sheets or Standard Boards: Supawood won’t sell you raw, unfinished MDF. They also don’t offer different MDF sheet sizes, thicknesses, or grades. These are things you would need for joinery, cabinetmaking, or DIY projects.

No Moisture-Resistant or Specialty MDF: You won’t find special MDF types from Supawood. This includes options like MR (moisture resistant) or zero-formaldehyde panels. They also don’t offer cut-to-size services for raw boards, which I know many MDF brands do.

Focus on Interior Finish & Acoustic Performance: In my opinion, their value is the final look and sound performance. They don’t focus on providing the base material for making cabinets or furniture.

Recommendation and Suitability

Does your project need raw MDF, special MDF sheets, or custom-sized boards? If you’re working on joinery, cabinets, or manufacturing, then I suggest you do not contact Supawood.

For things like specific environmental information, wholesale prices, or technical data on MDF, I recommend you look at dedicated Australian suppliers. Based on my experience, FA Mitchell, Plyco, and Trademaster are great choices.

I would recommend Supawood for architectural projects. They are a great fit if you need high-end lining panels that are ready to install. This is especially true if your main goals are appearance and sound control.

Are you unsure about the base materials? Or do you need the finish to meet a sustainability goal? I suggest you reach out to Supawood for their product details and paperwork.

Plywood Australia

Main Uses and Market Segments

Residential Construction: I see plywood used all the time for new homes, renovations, and fit-outs.

Commercial Projects: Offices, retail stores, and infrastructure projects all increase plywood sales.

Furniture Manufacturing: Demand is growing. The furniture sector is expected to grow at a 5.8% CAGR from 2025 to 2033.

Flooring Specialty: This is a solid niche for architectural and prefabricated building.

Buying trends differ for new construction versus replacement jobs. Demand also changes by region—NSW, Victoria, Queensland, and WA are very strong markets. In my opinion, Softwood plywood is the most common type used.

Leading Plywood Suppliers and Brands

Here are some of the leading suppliers I think you should know:

– Austral Plywoods Pty Ltd – A well-known local maker.

– Borg Manufacturing – Has a large presence and a wide range of products.

– Parkside Plywood – Popular for its sustainable plywood.

– Plyco – Focuses on quality and new designs.

– FormPly – A specialist in plywood formwork.

– Hume Doors & Timber – A leading supplier in Victoria.

– James Hardie Australia – Offers a wide variety of engineered wood products.

– Big River Group – Operates across the country and in local regions.

– Auswood International & IPL Plywood Ltd – Importers and major distributors.

International brands like Wisa Plywood, Koskisen, and Metsä Group compete in this region. This gives buyers more choices but puts pressure on local producers.

Market Data and Trade Highlights

In 2023, Australia imported $470 million worth of plywood. This made it the 6th largest importer in the world. Cheaper imports create tough competition for local producers, coming from major international suppliers.

Technology, Sustainability, and Trends

From what I’ve seen, AI-driven quality control and auto defect detection are now standard in top factories.

Predictive maintenance helps cut costs and prevent downtime.

Local suppliers now use new digital platforms. These connect them with trade and retail buyers, which improves access and lowers costs.

Sustainability is very important now. I notice that buyers and authorities ask for certified, green plywood, even if it raises costs.

Industry Challenges and Recent Moves

The main challenges I see are unstable global timber prices, supply chain problems, labor shortages, and the high cost of following Australia’s strict environmental rules.

Here are some recent industry moves I find interesting:

– Vertical integration: Big players now handle their own timber sourcing, production, and shipping. I believe this helps them improve efficiency and control their profit margins.

– Expansion in growth areas: Companies are opening factories and distribution centers closer to busy construction zones.

– Partnerships: I like that suppliers are collaborating with architects, builders, and designers. They work together to offer custom, high-value plywood solutions.

ROCPLEX (ROCPLY) – A Top MDF Supplier for Australia

Complete MDF Product Selection

Standard Raw MDF: These panels are made from wood fibers and resin. The result is a smooth, even surface. I find them great for painting, cutting, and other wood projects.

Moisture-Resistant MDF (MR MDF): This MDF is made for damp places. I recommend it for kitchens, laundries, and bathrooms.

Fire-Rated MDF: If fire safety is a priority, I suggest this option. It’s a good fit for commercial spaces, doors, and wall panels.

Melamine-Faced MDF: These come in many finishes, like high gloss, wood grain, and textured styles. A key feature I appreciate is that all panels are E0 grade. This means they have low formaldehyde, which is better for indoor air quality.

Sustainability and Certifications

E0 Formaldehyde Emissions: It’s good to know their melamine and MDF panels meet strict E0 standards. This makes indoor spaces safer to breathe in.

Environmental Compliance: ROCPLEX has top certifications like ISO 9001, ISO 14001, CE, and JAS-ANZ. In my opinion, these show a real commitment to quality and the environment. This helps support green building in Australia and other countries.

Global Reach: They ship their products to over 100 countries. This shows their quality is consistent and meets global standards.

Customization and Great Prices

Great Prices: I find ROCPLEX MDF offers great value. It performs well without breaking the bank, which is perfect for projects on a budget.

Standard and Custom Sizes: You can get sheets in standard Australian sizes, like 2440 x 1220mm. Thicknesses range from 1mm to 32mm. If you need something different, they can also do custom sizes.

OEM and ODM Options: ROCPLEX offers custom solutions. This means Australian clients can order panels with their own branding and specific designs.

Applications and Market Focus

Many Uses: I’ve seen ROCPLEX MDF used for many things in Australia. This includes furniture, cabinets, wall panels, and shop displays like Melamine Slatwall. It’s also great for commercial interiors.

One-Stop Shop: ROCPLEX is both a wholesaler and a maker. They can handle big and custom orders. I like that they also help find materials, which can make projects run smoother.

Logistics and Manufacturer Support

Reliable Logistics: ROCPLEX has a strong supply chain. Their quality control teams and large production capacity ensure you get what you need. They produce over 1,000,000 m³ of wood panels each year.

Local Brand: The products come from China’s Home World Group. In Australia, they are sold as ROCPLY. I find this helps keep quality and support consistent for local buyers.

Key Advantages for Australian Buyers

Product Variety: They have a board for almost any MDF job. You can get raw, specialty, or decorative panels.

Eco-Friendly: Their E0 low-emission products are a great choice for green building. I recommend them for creating healthier indoor spaces.

Good Prices: You get good pricing, whether your project is standard or custom.

Easy Customization: It’s simple to order custom sizes, thicknesses, and finishes.

Trusted Quality: With many international certifications and modern production, you can trust their products.